Question

J.K Mfg. Company produces golf carts. The company expects to sell 10,000 units yearly. Currently, the company produces the engines to power the golf carts.

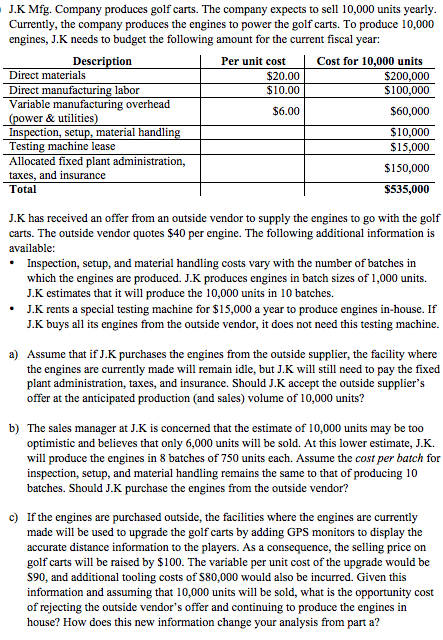

J.K Mfg. Company produces golf carts. The company expects to sell 10,000 units yearly. Currently, the company produces the engines to power the golf carts. To produce 10,000 engines, J.K needs to budget the following amount for the current fiscal year:

J.K Mfg. Company produces golf carts. The company expects to sell 10,000 units yearly. Currently, the company produces the engines to power the golf carts. To produce 10,000 engines, J.K needs to budget the following amount for the current fiscal year:

| Description | Per unit cost | Cost for 10,000 units |

| Direct materials | $20.00 | $200,000 |

| Direct manufacturing labor | $10.00 | $100,000 |

| Variable manufacturing overhead (power & utilities) | $6.00 | $60,000 |

| Inspection, setup, material handling |

| $10,000 |

| Testing machine lease |

| $15,000 |

| Allocated fixed plant administration, taxes, and insurance |

| $150,000 |

| Total |

| $535,000 |

J.K has received an offer from an outside vendor to supply the engines to go with the golf carts. The outside vendor quotes $40 per engine. The following additional information is available:

Inspection, setup, and material handling costs vary with the number of batches in which the engines are produced. J.K produces engines in batch sizes of 1,000 units. J.K estimates that it will produce the 10,000 units in 10 batches.

J.K rents a special testing machine for $15,000 a year to produce engines in-house. If J.K buys all its engines from the outside vendor, it does not need this testing machine.

Assume that if J.K purchases the engines from the outside supplier, the facility where the engines are currently made will remain idle, but J.K will still need to pay the fixed plant administration, taxes, and insurance. Should J.K accept the outside suppliers offer at the anticipated production (and sales) volume of 10,000 units?

The sales manager at J.K is concerned that the estimate of 10,000 units may be too optimistic and believes that only 6,000 units will be sold. At this lower estimate, J.K. will produce the engines in 8 batches of 750 units each. Assume the cost per batch for inspection, setup, and material handling remains the same to that of producing 10 batches. Should J.K purchase the engines from the outside vendor?

If the engines are purchased outside, the facilities where the engines are currently made will be used to upgrade the golf carts by adding GPS monitors to display the accurate distance information to the players. As a consequence, the selling price on golf carts will be raised by $100. The variable per unit cost of the upgrade would be $90, and additional tooling costs of $80,000 would also be incurred. Given this information and assuming that 10,000 units will be sold, what is the opportunity cost of rejecting the outside vendors offer and continuing to produce the engines in house? How does this new information change your analysis from part a?

J.K Mfg. Company produces golf carts. The company expects to sell 10,000 units yearly Currently, the company produces the engines to power the golf carts. To produce 10,000 engines, J.K needs to budget the following amount for the current fiscal year: Description Per unit cost Cost for 10,000 units Direct materials Direct manufacturing labor Variable manufacturing overhead $20.00 $10.00 $200,000 $100,000 S60,000 $10,000 $15,000 $150,000 S535,000 $6.00 er &utilities material handlirn Inspection, s Testing machine lease Allocated fixed plant administration, taxes, and insurance Total J.K has received an offer from an outside vendor to supply the engines to go with the golf carts. The outside vendor quotes $40 per engine. The following additional information is available: *Inspection, setup, and material handling costs vary with the number of batches in which the engines are produced. J.K produces engines in batch sizes of 1,000 units. K estimates that it will produce the 10,000 units in 10 batches. J.K rents a special testing machine for $15,000 a year to produce engines in-house. If J.K buys all its engines from the outside vendor, it does not need this testing machine. a) Assume that if J.K purchases the engines from the outside supplier, the facility where the engines are currently made will remain idle, but J.K will still need to pay the fixed plant administration, taxes, and insurance. Should J.K accept the outside supplier's offer at the anticipated production (and sales) volume of 10,000 units? b) The sales manager at J.K is concerned that the estimate of 10,000 units may be too optimistic and believes that only 6,000 units will be sold. At this lower estimate, J.K. will produce the engines in 8 batches of 750 units each. Assume the cost per batch for inspection, setup, and material handling remains the same to that of producing 10 batches. Should J.K purchase the engines from the outside vendor? c) If the engines are purchased outside, the facilities where the engines are currently made will be used to upgrade the golf carts by adding GPS monitors to display the accurate distance information to the players. As a consequence, the selling price on golf carts will be raised by $100. The variable per unit cost of the upgrade would be S90, and additional tooling costs of S80,000 would also be incurred. Given this information and assuming that 10,000 units will be sold, what is the opportunity cost of rejecting the outside vendor's offer and continuing to produce the engines in house? How does this new information change your analysis from part a

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started