just need the answers of 4.4, 4.9, 4.11, 4.12 and 4.14

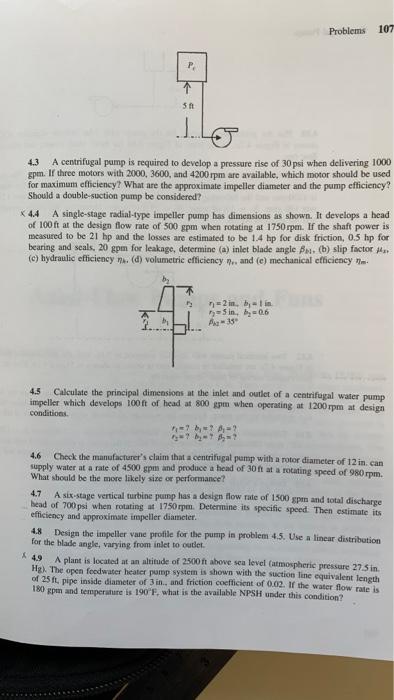

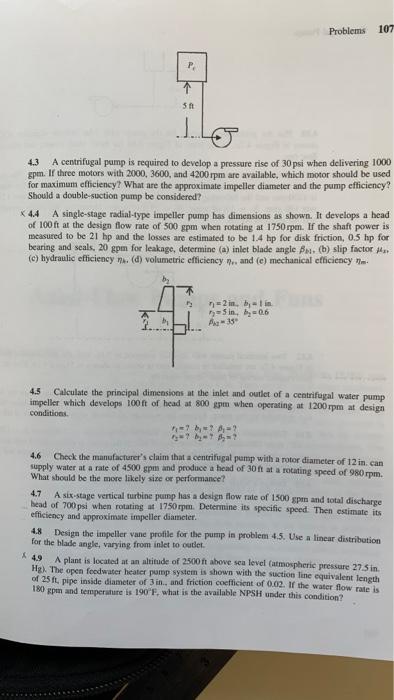

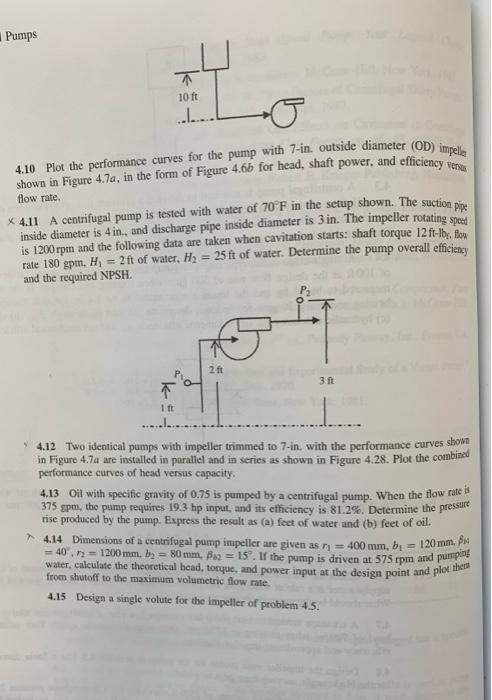

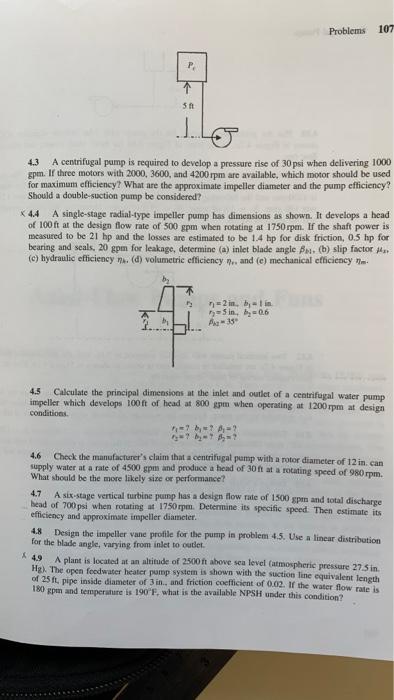

Problems 107 P. 51 5 4.3 A centrifugal pump is required to develop a pressure rise of 30 psi when delivering 1000 gpm. If three motors with 2000, 3600, and 4200 rpm are available, which motor should be used for maximum efficiency? What are the approximate impeller diameter and the pump efficiency? Should a double-suction pump be considered? K 4.4 A single-stage radial-type impeller pump has dimensions as shown. It develops a head of 100 ft at the design flow rate of 500 gpm when rotating at 1750 rpm. If the shaft power is measured to be 21 hp and the losses are estimated to be 1.4 hp for disk friction, 0.5 hp for bearing and seals, 20 gpm for leakage, determine (a) inlet blade angle Pa, (b) slip factor . (c) hydraulic efficiency n. (d) volumetric efficiency W..and (e) mechanical efficiency 1m = 2 in 1 in Sin, by 0.6 4 4.5 Calculate the principal dimensions at the inlet and outlet of a centrifugal water pump impeller which develops 100ft of head at 800 gpm when operating at 1200 rpm at design conditions ? ? ? -? 4.6 Check the manufacturer's claim that a centrifugal pump with a rotor diameter of 12 in, can supply water at a rate of 4500 gpm and produce a head of 30 at a rotating speed of 980 rpm. What should be the more likely size or performance? 4.7 A six-stage vertical turbine pump has a design flow rate of 1500 spm and total discharge head of 700 psi when rotating at 1750 rpm. Determine its specific speed. Then estimate its efficiency and approximate impeller diameter 4.8 Design the impeller vane profile for the pump in problem 4.5. Use a linear distribution for the blade angle, varying from inlet to outlet A 49 A plant is located at an altitude of 2500 above sea level atmospheric pressure 27.5 in. Hg). The open feedwater heater pump system is shown with the suction line equivalent length of 25ft. pipe inside diameter of 3 in.. and friction coefficient of 0.02. If the water flow rate is 180 ppm and temperature is 190F. what is the available NPSH under this condition? Pumps 10 ft flow rate. 4.10 Plot the performance curves for the pump with 7-in. outside diameter (OD) impelle shown in Figure 4.7a, in the form of Figure 4.6b for head, shaft power, and efficiency * 4.11 A centrifugal pump is tested with water of 70F in the setup shown. The suction pige inside diameter is 4 in, and discharge pipe inside diameter is 3 in. The impeller rotating speed is 1200 rpm and the following data are taken when cavitation starts: shaft torque 12 ft-lby. How rate 180 gpm. H1 = 2 ft of water, H2 = 25ft of water. Determine the pump overall efficiency and the required NPSH. Pio 2.ft 31 11 I. 4.12 Two identical pumps with impeller trimmed to 7-in, with the performance curves shown in Figure 4.7a are installed in parallel and in series as shown in Figure 4.28. Plot the combined performance curves of head versus capacity. 4.13 Oil with specific gravity of 0.75 is pumped by a centrifugal pump. When the flow rate is 375 gpm, the pump requires 19.3 hp input and its efficiency is 81.29. Determine the pressure rise produced by the pump. Express the result as (a) feet of water and (b) feet of oil. 4.14 Dimensions of a centrifugal pump impeller are given as 11 = 400 mm, bi = 120mm. Bu = 40. n = 1200 mm, b> = 80 mm. Be2 = 15. If the pump is driven at 575 rpm and pumping water, calculate the theoretical head, torque, and power input at the design point and plot theat from shutoff to the maximum volumetric flow rate 4.15 Design a single volute for the impeller of problem 4.5