kindly solve these problems

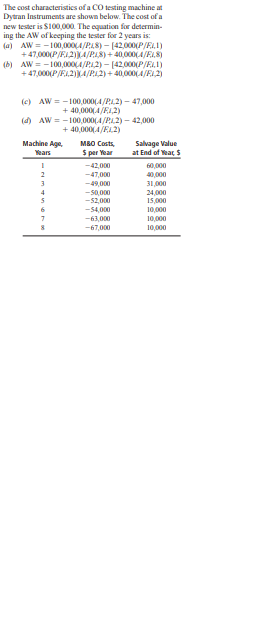

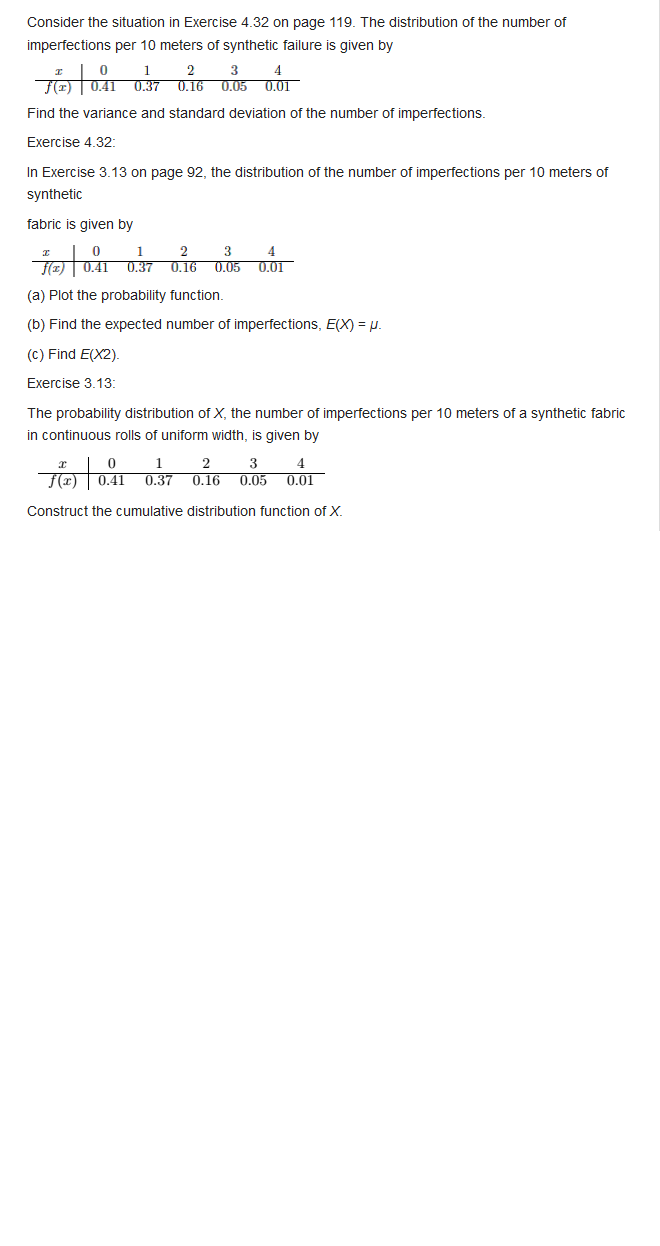

Keep or Replace the Kiln Case PE In Example 1 1.8, the in-place kiln and replacement killm (GH) were evaluated using a fixed study pe- riod of & years. This is a significantly shortened period compared to the expected 12-year life of the challenger. Use the best estimates available throughout this case to determine the impact on the capital recovery amount for the GH kiln of short- ening the evaluation time from 12 to 6 years. Nabisco Bakers currently employs staff to operate the equipment used to sterilize much of the mixing, baking, and packaging facilities in a large cookie and cracker manufacturing plant in lowa. The plant manager, who is dedicated to cutting costs but not sacrificing quality and hygiene, has the projected data shown in the table below if the current system were retained for up to its maximum expected life of 3 years. A contract company has proposed a turnkey sanitation system for $5 0 million per year if Nabisco signs on for 4 to 10 years, and $5.$ mil- ion per year for a shorter number of years. Retained AM, $ per Year Close.Down Expense, $ -3,000,000 -2,300,000 -2 500,000 -2,300,000 -2 000,000 -3,000,000 -1,000 00D -3,000,000 -1,000,000 -3 5001000 -500,000 (4) At a MARR = 8% per year, perform a re- placement study for the plant manager with fixed study period of 3 years, when it is an- ticipated that the plant will be shut down due to the age of the facility and projected tech- nological obsolescence. As you perform the study, take into account that regardless of the number of years that the current sanitation system is retained, a one-time close-downThe cost characteristics of a CO testing machine at Dytran Instruments are shown below. The cost of a new fester is $100,000. The equation for determin- ing the AW of keeping the tester for 2 years is: (a] AW = -100,1004/PAS) - [42,010(P/F,1) + 4700(P/F31 4/PS) +40,000(4/F,5) (8) AW = -100,000(4/P12) - [42000(P/F,1) + 47000(P/F12)](4/P13) + 4000(4/F 2) (C) AW = -100,000(4/242) - 47,000 () AW = -100,000(4/243) - 42,000 Machine Age, MBO Costs, Salvage Value Years $ per Year at End of Wear, $ -42,000 -47.0DO -49.000 31,000 -90,000 24,030 -52,000 15 030 -54,000 -63,000 -67,000\f\f\f