knowing that NPV = -102554, ROI = -2.6

this is intro but do not think is related rather than finding ROI and NPV which i done with it and given to you

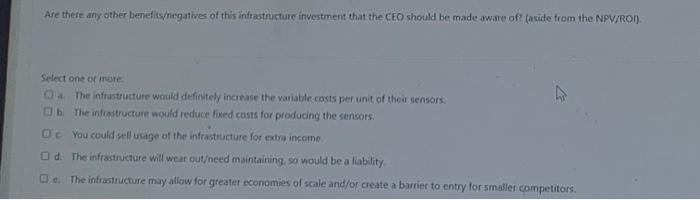

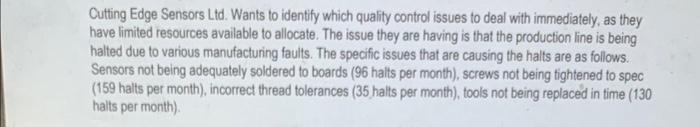

Are there atiy other benefitsegatives of this infrastructure investment that the C.EO should be made aware of? (aside from the NPV/ROD Select one or more: a The inftastructure would definitely increase the variable costs per unit of theit sensors: b. The infisitructure would reduce fixed costs for producing the sensors: You could sell usige of the infrastructure for extra income. d. The infrastructure will wear outeed maintaining so would be a lability. c. The infrastructure may allow for greater economies of scale and/or create a bamier to entry for smaller competitors. Cutting Edge Sensors Ltd. Wants to identify which quality control issues to deal with immediately, as they have limited resources available to allocate. The issue they are having is that the production line is being halted due to various manufacturing faults. The specific issues that are causing the halts are as follows. Sensors not being adequately soldered to boards ( 96 halts per month). screws not being tightened to spec (159 halts per month), incorrect thread tolerances ( 35 halts per month), tools not being replaced in time ( 130 halts per month). Are there atiy other benefitsegatives of this infrastructure investment that the C.EO should be made aware of? (aside from the NPV/ROD Select one or more: a The inftastructure would definitely increase the variable costs per unit of theit sensors: b. The infisitructure would reduce fixed costs for producing the sensors: You could sell usige of the infrastructure for extra income. d. The infrastructure will wear outeed maintaining so would be a lability. c. The infrastructure may allow for greater economies of scale and/or create a bamier to entry for smaller competitors. Cutting Edge Sensors Ltd. Wants to identify which quality control issues to deal with immediately, as they have limited resources available to allocate. The issue they are having is that the production line is being halted due to various manufacturing faults. The specific issues that are causing the halts are as follows. Sensors not being adequately soldered to boards ( 96 halts per month). screws not being tightened to spec (159 halts per month), incorrect thread tolerances ( 35 halts per month), tools not being replaced in time ( 130 halts per month)