Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Laramie Company has a traditional, unit-based cost system. The Kansas City plant of Laramie produces eight different electronic products. Each year, 100,000 units of

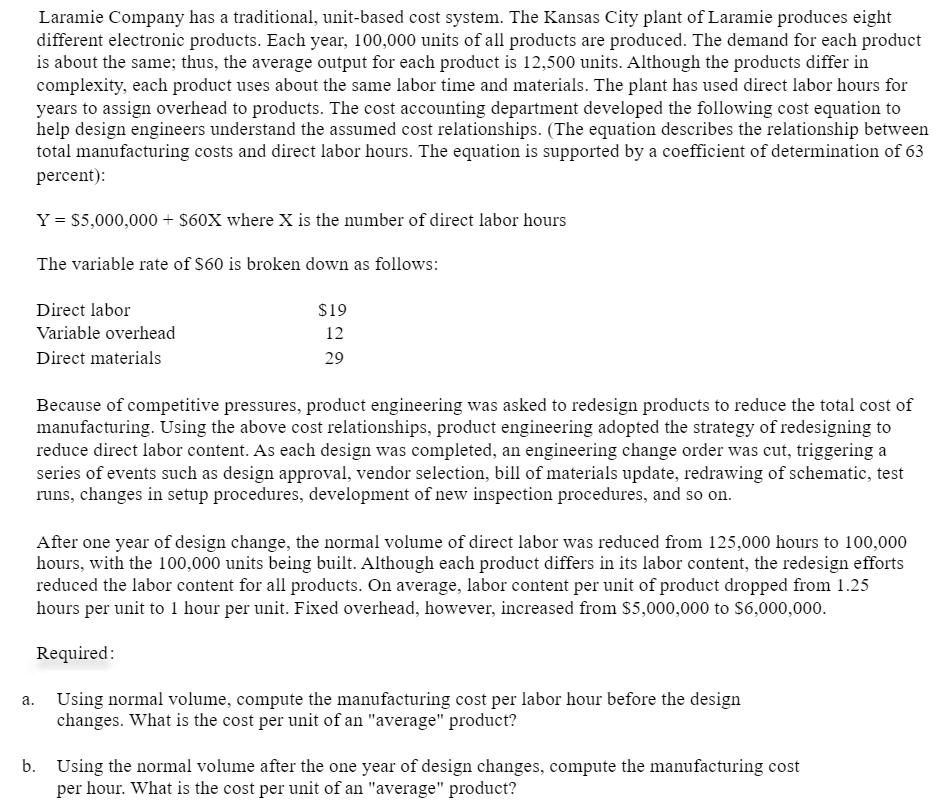

Laramie Company has a traditional, unit-based cost system. The Kansas City plant of Laramie produces eight different electronic products. Each year, 100,000 units of all products are produced. The demand for each product is about the same; thus, the average output for each product is 12,500 units. Although the products differ in complexity, each product uses about the same labor time and materials. The plant has used direct labor hours for years to assign overhead to products. The cost accounting department developed the following cost equation to help design engineers understand the assumed cost relationships. (The equation describes the relationship between total manufacturing costs and direct labor hours. The equation is supported by a coefficient of determination of 63 percent): Y = $5,000,000 + $60X where X is the number of direct labor hours The variable rate of S60 is broken down as follows: Direct labor $19 Variable overhead 12 Direct materials 29 Because of competitive pressures, product engineering was asked to redesign products to reduce the total cost of manufacturing. Using the above cost relationships, product engineering adopted the strategy of redesigning to reduce direct labor content. As each design was completed, an engineering change order was cut, triggering a series of events such as design approval, vendor selection, bill of materials update, redrawing of schematic, test runs, changes in setup procedures, development of new inspection procedures, and so on. After one year of design change, the normal volume of direct labor was reduced from 125,000 hours to 100,000 hours, with the 100,000 units being built. Although each product differs in its labor content, the redesign efforts reduced the labor content for all products. On average, labor content per unit of product dropped from 1.25 hours per unit to 1 hour per unit. Fixed overhead, however, increased from $5,000,000 to $6,000,000. Required: Using normal volume, compute the manufacturing cost per labor hour before the design changes. What is the cost per unit of an "average" product? . b. Using the normal volume after the one year of design changes, compute the manufacturing cost per hour. What is the cost per unit of an "average" product?

Step by Step Solution

★★★★★

3.32 Rating (158 Votes )

There are 3 Steps involved in it

Step: 1

aCost per labor hour 5000000 60 125000 1250...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started