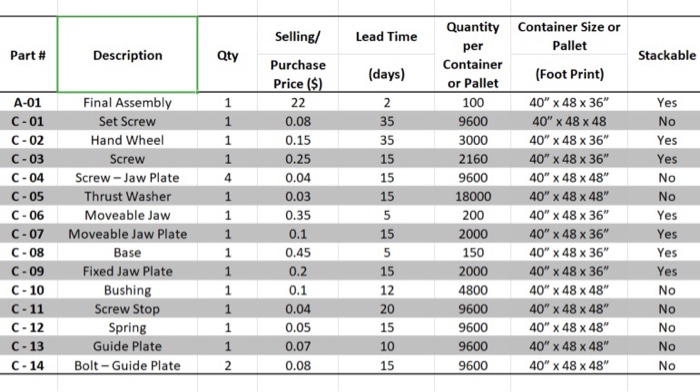

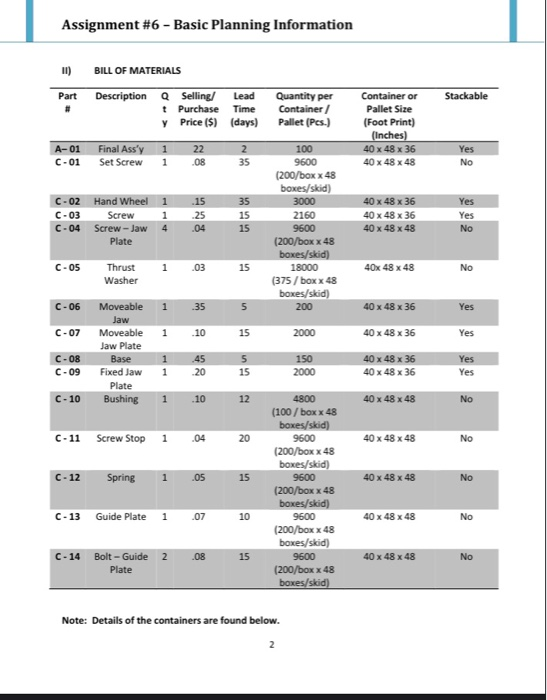

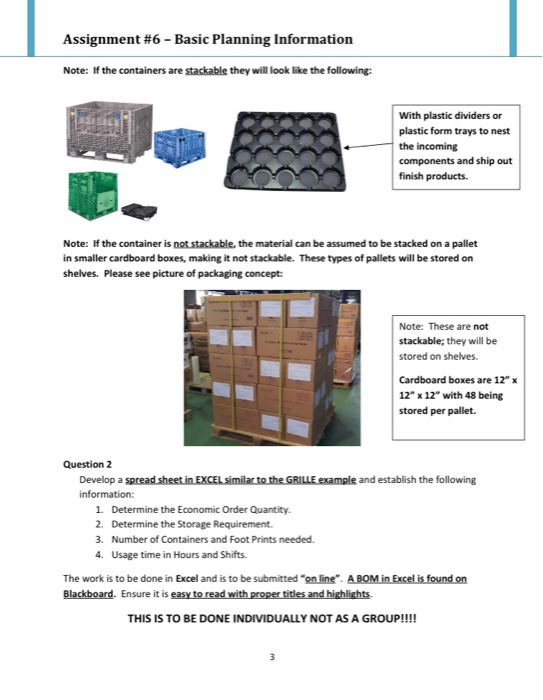

Lead Time Part # Description Qty Stackable 1 1 1 1 4. 1 Selling/ Purchase Price ($) 22 0.08 0.15 0.25 0.04 0.03 0.35 0.1 0.45 0.2 A-01 C-01 C-02 C-03 C-04 C-05 C-06 C-07 C-08 C-09 C-10 C-11 C-12 C-13 C-14 Yes No Yes Yes No No Yes 1 Quantity Container Size or per Pallet Container (Foot Print) or Pallet 100 40" x 48 x 36" 9600 40" x 48 x 48 3000 40" x 48 x 36" 2160 40" x 48 x 36" 9600 40" x 48 x 48" 18000 40" x 48 x 48" 40" x 48 x 36" 2000 40" x 48 x 36" 150 40" x 48 x 36" 2000 40" x 48 x 36" 4800 40" x 48 x 48" 9600 40" x 48 x 48" 9600 40" x 48 x 48" 9600 40" x 48 x 48" 9600 40" x 48 x 48" (days) 2. 35 35 15 15 15 5 15 5 15 12 20 15 10 15 Final Assembly Set Screw Hand Wheel Screw Screw - Jaw Plate Thrust Washer Moveable Jaw Moveable Jaw Plate Base Fixed Jaw Plate Bushing Screw Stop Spring Guide Plate Bolt - Guide Plate 200 Yes Yes Yes 1 1 1 1 1 1 1 2 0.1 No 0.04 0.05 0.07 0.08 No No No No Assignment #6 - Basic Planning Information Universal Clamping Devices is located in Northern Ontario and is known for their clamping devices for the domestic and commercial industry. Management has set a strategic direction to implement Lean principles to minimize inventory requirements and to optimize their floor space in their facility. The product which they want to analyze is their Bench Vice product which represents over 50% of their sales. The product exploded view is found below: re 10 1) OPERATIONS ASSUMTIONS a) Customer Daily Demand: 900 Assemblies. b) Available Working Days: 242 Days. c) Available Shifts: 2 Shifts (8 hours per shift). d) Scrap: 3% e) Rework: 1% f) Available Time: 420 minutes per shift B) Holding Cost: 30% of purchase or selling price. h) Set up / Ordering Cost: $35 i) Maximum Stacking Height 4 containers i) Demand Variation (0) 15.0 k) Service Cycle Variation = 95 (z = 1.65) Question 1 From the above information calculate the following: 1. Daily requirements including scrap and rework. 2. Yearly requirements 3. TAKT time. 4. Process Capacity (pcs./ Hr.). Assignment #6 - Basic Planning Information 1) BILL OF MATERIALS Stackable Part Description Selling/ Lead t Purchase Time y Price ($) (days) A-01 Final Ass'y 1 22 2 C-01 Set Screw 1 .08 35 Quantity per Container Pallet (Pes.) Container or Pallet Size (Foot Print) (Inches) 40 x 48 x 36 40 x 48 x 48 Yes No C-02 Hand Wheel 1 C-03 Screw 1 C-04 Screw - Jaw 4 Plate .15 .25 .04 35 15 15 100 9600 (200/box X 48 boxes/skid) 3000 2160 9600 (200/box x 48 boxes/skid) 18000 (375 / box X 48 boxes/skid) 200 40 x 48 x 36 40 x 48 x 36 40 x 48 x 48 Yes Yes No C-05 1 .03 15 40x 48 x 48 No Thrust Washer C-06 1 35 5 40 x 48 x 36 Yes C-07 1 10 15 2000 40 x 48 x 36 Yes Moveable Jaw Moveable Jaw Plate Base Fixed Jaw Plate Bushing C-08 C-09 1 45 1 .20 5 15 150 2000 40 x 48 x 36 40 x 48 x 36 Yes Yes C-10 1 10 12 40 x 48 x 48 No C-11 Screw Stop 1 .04 20 40 x 48 x 48 No C-12 Spring 1 .05 15 40 x 48 x 48 No 4800 (100 / box X 48 boxes/skid) 9600 (200/box x 48 boxes/skid) 9600 (200/box X 48 boxes/skid) 9600 (200/box X 48 boxes/skid) 9600 (200/box X 48 boxes/skid) C-13 Guide Plate 1 .07 10 40 x 48 x 48 No C-14 Bolt - Guide 2 Plate .08 15 40 x 48 x 48 No Note: Details of the containers are found below. 2 Assignment #6 - Basic Planning Information Note: If the containers are stackable they will look like the following: With plastic dividers or plastic form trays to nest the incoming components and ship out finish products. Note: If the container is not stackable, the material can be assumed to be stacked on a pallet in smaller cardboard boxes, making it not stackable. These types of pallets will be stored on shelves. Please see picture of packaging concept: Note: These are not stackable; they will be stored on shelves. Cardboard boxes are 12" 12" x 12" with 48 being stored per pallet. Question 2 Develop a spread sheet in EXCEL similar to the GRILLE example and establish the following information: 1. Determine the Economic Order Quantity 2. Determine the Storage Requirement. 3. Number of Containers and Foot Prints needed. 4. Usage time in Hours and Shifts. The work is to be done in Excel and is to be submitted "online". A BOM in Excel is found on Blackboard. Ensure it is easy to read with proper titles and highlights THIS IS TO BE DONE INDIVIDUALLY NOT AS A GROUP!!!! 3 Lead Time Part # Description Qty Stackable 1 1 1 1 4. 1 Selling/ Purchase Price ($) 22 0.08 0.15 0.25 0.04 0.03 0.35 0.1 0.45 0.2 A-01 C-01 C-02 C-03 C-04 C-05 C-06 C-07 C-08 C-09 C-10 C-11 C-12 C-13 C-14 Yes No Yes Yes No No Yes 1 Quantity Container Size or per Pallet Container (Foot Print) or Pallet 100 40" x 48 x 36" 9600 40" x 48 x 48 3000 40" x 48 x 36" 2160 40" x 48 x 36" 9600 40" x 48 x 48" 18000 40" x 48 x 48" 40" x 48 x 36" 2000 40" x 48 x 36" 150 40" x 48 x 36" 2000 40" x 48 x 36" 4800 40" x 48 x 48" 9600 40" x 48 x 48" 9600 40" x 48 x 48" 9600 40" x 48 x 48" 9600 40" x 48 x 48" (days) 2. 35 35 15 15 15 5 15 5 15 12 20 15 10 15 Final Assembly Set Screw Hand Wheel Screw Screw - Jaw Plate Thrust Washer Moveable Jaw Moveable Jaw Plate Base Fixed Jaw Plate Bushing Screw Stop Spring Guide Plate Bolt - Guide Plate 200 Yes Yes Yes 1 1 1 1 1 1 1 2 0.1 No 0.04 0.05 0.07 0.08 No No No No Assignment #6 - Basic Planning Information Universal Clamping Devices is located in Northern Ontario and is known for their clamping devices for the domestic and commercial industry. Management has set a strategic direction to implement Lean principles to minimize inventory requirements and to optimize their floor space in their facility. The product which they want to analyze is their Bench Vice product which represents over 50% of their sales. The product exploded view is found below: re 10 1) OPERATIONS ASSUMTIONS a) Customer Daily Demand: 900 Assemblies. b) Available Working Days: 242 Days. c) Available Shifts: 2 Shifts (8 hours per shift). d) Scrap: 3% e) Rework: 1% f) Available Time: 420 minutes per shift B) Holding Cost: 30% of purchase or selling price. h) Set up / Ordering Cost: $35 i) Maximum Stacking Height 4 containers i) Demand Variation (0) 15.0 k) Service Cycle Variation = 95 (z = 1.65) Question 1 From the above information calculate the following: 1. Daily requirements including scrap and rework. 2. Yearly requirements 3. TAKT time. 4. Process Capacity (pcs./ Hr.). Assignment #6 - Basic Planning Information 1) BILL OF MATERIALS Stackable Part Description Selling/ Lead t Purchase Time y Price ($) (days) A-01 Final Ass'y 1 22 2 C-01 Set Screw 1 .08 35 Quantity per Container Pallet (Pes.) Container or Pallet Size (Foot Print) (Inches) 40 x 48 x 36 40 x 48 x 48 Yes No C-02 Hand Wheel 1 C-03 Screw 1 C-04 Screw - Jaw 4 Plate .15 .25 .04 35 15 15 100 9600 (200/box X 48 boxes/skid) 3000 2160 9600 (200/box x 48 boxes/skid) 18000 (375 / box X 48 boxes/skid) 200 40 x 48 x 36 40 x 48 x 36 40 x 48 x 48 Yes Yes No C-05 1 .03 15 40x 48 x 48 No Thrust Washer C-06 1 35 5 40 x 48 x 36 Yes C-07 1 10 15 2000 40 x 48 x 36 Yes Moveable Jaw Moveable Jaw Plate Base Fixed Jaw Plate Bushing C-08 C-09 1 45 1 .20 5 15 150 2000 40 x 48 x 36 40 x 48 x 36 Yes Yes C-10 1 10 12 40 x 48 x 48 No C-11 Screw Stop 1 .04 20 40 x 48 x 48 No C-12 Spring 1 .05 15 40 x 48 x 48 No 4800 (100 / box X 48 boxes/skid) 9600 (200/box x 48 boxes/skid) 9600 (200/box X 48 boxes/skid) 9600 (200/box X 48 boxes/skid) 9600 (200/box X 48 boxes/skid) C-13 Guide Plate 1 .07 10 40 x 48 x 48 No C-14 Bolt - Guide 2 Plate .08 15 40 x 48 x 48 No Note: Details of the containers are found below. 2 Assignment #6 - Basic Planning Information Note: If the containers are stackable they will look like the following: With plastic dividers or plastic form trays to nest the incoming components and ship out finish products. Note: If the container is not stackable, the material can be assumed to be stacked on a pallet in smaller cardboard boxes, making it not stackable. These types of pallets will be stored on shelves. Please see picture of packaging concept: Note: These are not stackable; they will be stored on shelves. Cardboard boxes are 12" 12" x 12" with 48 being stored per pallet. Question 2 Develop a spread sheet in EXCEL similar to the GRILLE example and establish the following information: 1. Determine the Economic Order Quantity 2. Determine the Storage Requirement. 3. Number of Containers and Foot Prints needed. 4. Usage time in Hours and Shifts. The work is to be done in Excel and is to be submitted "online". A BOM in Excel is found on Blackboard. Ensure it is easy to read with proper titles and highlights THIS IS TO BE DONE INDIVIDUALLY NOT AS A GROUP!!!! 3