Answered step by step

Verified Expert Solution

Question

1 Approved Answer

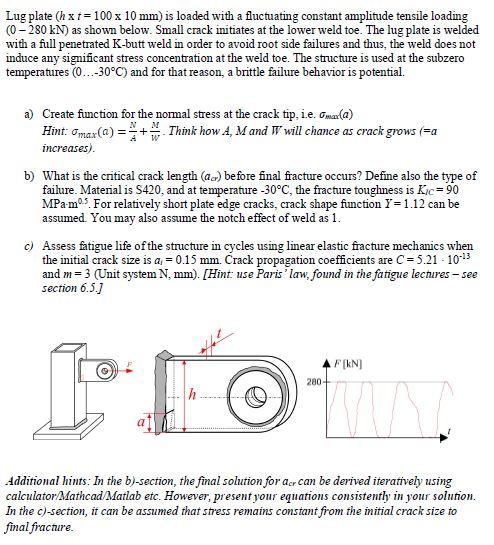

Lug plate (h xt = 100 x 10 mm) is loaded with a fluctuating constant amplitude tensile loading (0- 280 kN) as shown below.

Lug plate (h xt = 100 x 10 mm) is loaded with a fluctuating constant amplitude tensile loading (0- 280 kN) as shown below. Small crack initiates at the lower weld toe. The lug plate is welded with a full penetrated K-butt weld in order to avoid root side failures and thus, the weld does not induce any significant stress concentration at the weld toe. The structure is used at the subzero temperatures (0.-30C) and for that reason, a brittle failure behavior is potential. a) Create function for the nomal stress at the crack tip, i.e. omarla) Hint: Omar (a) =+. Think how A, Mand W will chance as crack grows (=a increases). b) What is the critical crack length (a) before final fracture occurs? Define also the type of failure. Material is S420, and at temperature -30C, the fracture toughness is Kic= 90 MPams. For relatively short plate edge cracks, crack shape fnction Y= 1.12 can be assumed. You may also assume the notch effect of weld as 1. c) Assess fatigue life of the structure in cycles using linear elastic fracture mechanics when the initial crack size is a, = 0.15 mm. Crack propagation coefficients are C= 5.21 - 1013 and m= 3 (Unit system N, mm). [Hint: use Paris law, found in the fatigue lectures - see section 6.5.] F(kN) 280- Additional hints: In the b)-section, the final solution for aer cam be derived iteratively using calculator/Mathcad/Matlab etc. However, present your equations consistently in your solution. In the c)-section, it can be assumed that stress remains constant from the initial crack size to final fracture.

Step by Step Solution

★★★★★

3.44 Rating (147 Votes )

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Document Format ( 2 attachments)

635e1646b3993_181339.pdf

180 KBs PDF File

635e1646b3993_181339.docx

120 KBs Word File

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started