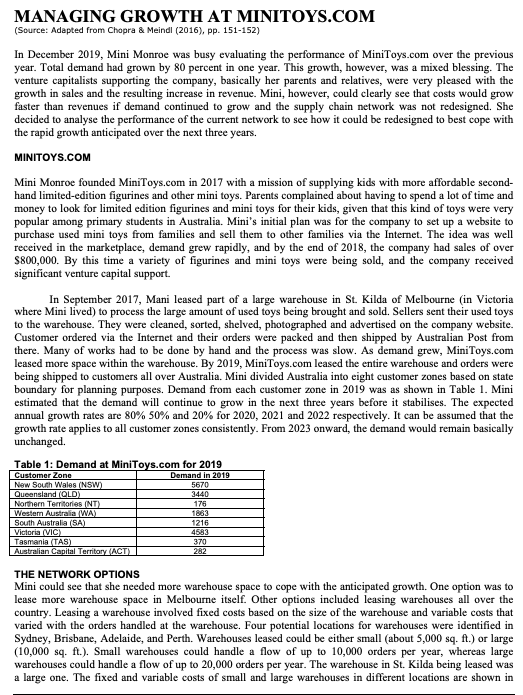

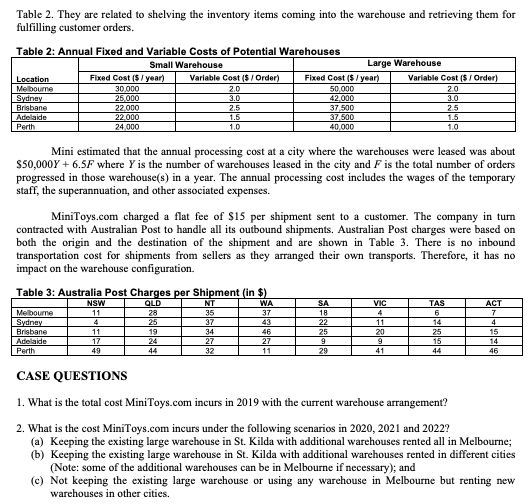

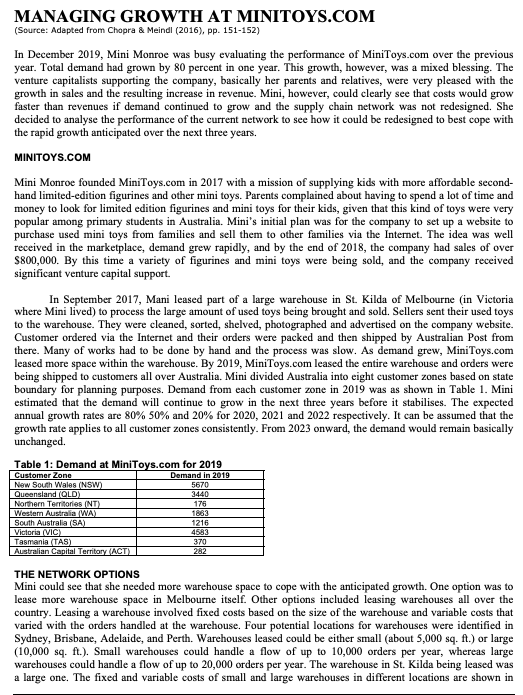

MANAGING GROWTH AT MINITOYS.COM (Source: Adapted from Chopra & Meindl (2016), pp. 151-152) In December 2019, Mini Monroe was busy evaluating the performance of MiniToys.com over the previous year. Total demand had grown by 80 percent in one year. This growth, however, was a mixed blessing. The venture capitalists supporting the company, basically her parents and relatives, were very pleased with the growth in sales and the resulting increase in revenue. Mini, however, could clearly see that costs would grow faster than revenues if demand continued to grow and the supply chain network was not redesigned. She decided to analyse the performance of the current network to see how it could be redesigned to best cope with the rapid growth anticipated over the next three years. MINITOYS.COM Mini Monroe founded MiniToys.com in 2017 with a mission of supplying kids with more affordable second- hand limited-edition figurines and other mini toys. Parents complained about having to spend a lot of time and money to look for limited edition figurines and mini toys for their kids, given that this kind of toys were very popular among primary students in Australia. Mini's initial plan was for the company to set up a website to purchase used mini toys from families and sell them to other families via the Internet. The idea was well received in the marketplace, demand grew rapidly, and by the end of 2018, the company had sales of over $800,000. By this time a variety of figurines and mini toys were being sold, and the company received significant venture capital support. In September 2017, Mani leased part of a large warehouse in St. Kilda of Melbourne (in Victoria where Mini lived) to process the large amount of used toys being brought and sold. Sellers sent their used toys to the warehouse. They were cleaned, sorted, shelved, photographed and advertised on the company website. Customer ordered via the Internet and their orders were packed and then shipped by Australian Post from there. Many of works had to be done by hand and the process was slow. As demand grew, MiniToys.com leased more space within the warehouse. By 2019, MiniToys.com leased the entire warehouse and orders were being shipped to customers all over Australia. Mini divided Australia into eight customer zones based on state boundary for planning purposes. Demand from each customer zone in 2019 was as shown in Table 1. Mini estimated that the demand will continue to grow in the next three years before it stabilises. The expected annual growth rates are 80% 50% and 20% for 2020, 2021 and 2022 respectively. It can be assumed that the growth rate applies to all customer zones consistently. From 2023 onward, the demand would remain basically unchanged. Table 1: Demand at MiniToys.com for 2019 Customer Zone New South Wales (NSW) Queensland (OLD) Northern Territories (NT) Western Australia (WA) South Australia (SA) Victoria (VIC) Tasmania (TAS) Australian Capital Territory (ACT) THE NETWORK OPTIONS Mini could see that she needed more warehouse space to cope with the anticipated growth. One option was to lease more warehouse space in Melbourne itself. Other options included leasing warehouses all over the country. Leasing a warehouse involved fixed costs based on the size of the warehouse and variable costs that varied with the orders handled at the warehouse. Four potential locations for warehouses were identified in Sydney, Brisbane, Adelaide, and Perth. Warehouses leased could be either small about 5,000 sq. ft.) or large (10,000 sq. ft.). Small warehouses could handle a flow of up to 10,000 orders per year, whereas large Warehouses could handle a flow of up to 20,000 orders per year. The warehouse in St. Kilda being leased was a large one. The fixed and variable costs of small and large warehouses in different locations are shown in Demand in 2019 5670 3440 176 1883 1216 4543 370 282 Table 2. They are related to shelving the inventory items coming into the warehouse and retrieving them for fulfilling customer orders. Table 2: Annual Fixed and Variable costs of Potential Warehouses Small Warehouse Large Warehouse Location Fixed Cost ($ / year) Variable Cost ($ / Order) Fixed Cost ($ / year) Variable Cost ($ / Order) Melbourne 30.000 2.0 50,000 20 Sydney 25.000 3.0 42.000 3.0 Brisbane 22.000 2.5 37,500 25 Adelaide 22.000 1.5 37,500 1.5 Perth 24.000 1.0 40.000 10 Mini estimated that the annual processing cost at a city where the warehouses were leased was about $50,000Y + 6.5F where Y is the number of warehouses leased in the city and F is the total number of orders progressed in those warehouse(s) in a year. The annual processing cost includes the wages of the temporary staff, the superannuation, and other associated expenses. MiniToys.com charged a flat fee of $15 per shipment sent to a customer. The company in turn contracted with Australian Post to handle all its outbound shipments. Australian Post charges were based on both the origin and the destination of the shipment and are shown in Table 3. There is no inbound transportation cost for shipments from sellers as they arranged their own transports. Therefore, it has no impact on the warehouse configuration. Table 3: Australia Post Charges per Shipment (in $) NSW QLD NT WA Melbourne 11 28 35 37 Sydney 25 37 Brisbane 11 19 34 46 Adelaide 17 24 27 27 Perth 49 32 11 SA 18 22 25 VIC 4 11 20 9 TAS 6 14 25 15 44 ACT 7 4 15 14 46 29 CASE QUESTIONS 1. What is the total cost MiniToys.com incurs in 2019 with the current warehouse arrangement? 2. What is the cost MiniToys.com incurs under the following scenarios in 2020, 2021 and 2022? (a) Keeping the existing large warehouse in St. Kilda with additional warehouses rented all in Melbourne; (6) Keeping the existing large warehouse in St. Kilda with additional warehouses rented in different cities (Note: some of the additional warehouses can be in Melbourne if necessary); and (C) Not keeping the existing large warehouse or using any warehouse in Melbourne but renting new warehouses in other cities. MANAGING GROWTH AT MINITOYS.COM (Source: Adapted from Chopra & Meindl (2016), pp. 151-152) In December 2019, Mini Monroe was busy evaluating the performance of MiniToys.com over the previous year. Total demand had grown by 80 percent in one year. This growth, however, was a mixed blessing. The venture capitalists supporting the company, basically her parents and relatives, were very pleased with the growth in sales and the resulting increase in revenue. Mini, however, could clearly see that costs would grow faster than revenues if demand continued to grow and the supply chain network was not redesigned. She decided to analyse the performance of the current network to see how it could be redesigned to best cope with the rapid growth anticipated over the next three years. MINITOYS.COM Mini Monroe founded MiniToys.com in 2017 with a mission of supplying kids with more affordable second- hand limited-edition figurines and other mini toys. Parents complained about having to spend a lot of time and money to look for limited edition figurines and mini toys for their kids, given that this kind of toys were very popular among primary students in Australia. Mini's initial plan was for the company to set up a website to purchase used mini toys from families and sell them to other families via the Internet. The idea was well received in the marketplace, demand grew rapidly, and by the end of 2018, the company had sales of over $800,000. By this time a variety of figurines and mini toys were being sold, and the company received significant venture capital support. In September 2017, Mani leased part of a large warehouse in St. Kilda of Melbourne (in Victoria where Mini lived) to process the large amount of used toys being brought and sold. Sellers sent their used toys to the warehouse. They were cleaned, sorted, shelved, photographed and advertised on the company website. Customer ordered via the Internet and their orders were packed and then shipped by Australian Post from there. Many of works had to be done by hand and the process was slow. As demand grew, MiniToys.com leased more space within the warehouse. By 2019, MiniToys.com leased the entire warehouse and orders were being shipped to customers all over Australia. Mini divided Australia into eight customer zones based on state boundary for planning purposes. Demand from each customer zone in 2019 was as shown in Table 1. Mini estimated that the demand will continue to grow in the next three years before it stabilises. The expected annual growth rates are 80% 50% and 20% for 2020, 2021 and 2022 respectively. It can be assumed that the growth rate applies to all customer zones consistently. From 2023 onward, the demand would remain basically unchanged. Table 1: Demand at MiniToys.com for 2019 Customer Zone New South Wales (NSW) Queensland (OLD) Northern Territories (NT) Western Australia (WA) South Australia (SA) Victoria (VIC) Tasmania (TAS) Australian Capital Territory (ACT) THE NETWORK OPTIONS Mini could see that she needed more warehouse space to cope with the anticipated growth. One option was to lease more warehouse space in Melbourne itself. Other options included leasing warehouses all over the country. Leasing a warehouse involved fixed costs based on the size of the warehouse and variable costs that varied with the orders handled at the warehouse. Four potential locations for warehouses were identified in Sydney, Brisbane, Adelaide, and Perth. Warehouses leased could be either small about 5,000 sq. ft.) or large (10,000 sq. ft.). Small warehouses could handle a flow of up to 10,000 orders per year, whereas large Warehouses could handle a flow of up to 20,000 orders per year. The warehouse in St. Kilda being leased was a large one. The fixed and variable costs of small and large warehouses in different locations are shown in Demand in 2019 5670 3440 176 1883 1216 4543 370 282 Table 2. They are related to shelving the inventory items coming into the warehouse and retrieving them for fulfilling customer orders. Table 2: Annual Fixed and Variable costs of Potential Warehouses Small Warehouse Large Warehouse Location Fixed Cost ($ / year) Variable Cost ($ / Order) Fixed Cost ($ / year) Variable Cost ($ / Order) Melbourne 30.000 2.0 50,000 20 Sydney 25.000 3.0 42.000 3.0 Brisbane 22.000 2.5 37,500 25 Adelaide 22.000 1.5 37,500 1.5 Perth 24.000 1.0 40.000 10 Mini estimated that the annual processing cost at a city where the warehouses were leased was about $50,000Y + 6.5F where Y is the number of warehouses leased in the city and F is the total number of orders progressed in those warehouse(s) in a year. The annual processing cost includes the wages of the temporary staff, the superannuation, and other associated expenses. MiniToys.com charged a flat fee of $15 per shipment sent to a customer. The company in turn contracted with Australian Post to handle all its outbound shipments. Australian Post charges were based on both the origin and the destination of the shipment and are shown in Table 3. There is no inbound transportation cost for shipments from sellers as they arranged their own transports. Therefore, it has no impact on the warehouse configuration. Table 3: Australia Post Charges per Shipment (in $) NSW QLD NT WA Melbourne 11 28 35 37 Sydney 25 37 Brisbane 11 19 34 46 Adelaide 17 24 27 27 Perth 49 32 11 SA 18 22 25 VIC 4 11 20 9 TAS 6 14 25 15 44 ACT 7 4 15 14 46 29 CASE QUESTIONS 1. What is the total cost MiniToys.com incurs in 2019 with the current warehouse arrangement? 2. What is the cost MiniToys.com incurs under the following scenarios in 2020, 2021 and 2022? (a) Keeping the existing large warehouse in St. Kilda with additional warehouses rented all in Melbourne; (6) Keeping the existing large warehouse in St. Kilda with additional warehouses rented in different cities (Note: some of the additional warehouses can be in Melbourne if necessary); and (C) Not keeping the existing large warehouse or using any warehouse in Melbourne but renting new warehouses in other cities