May I ask how to do with this homework andwhat model should I have ? Can you write the model for me? Or give briefly how to do with reference.Thanks you much

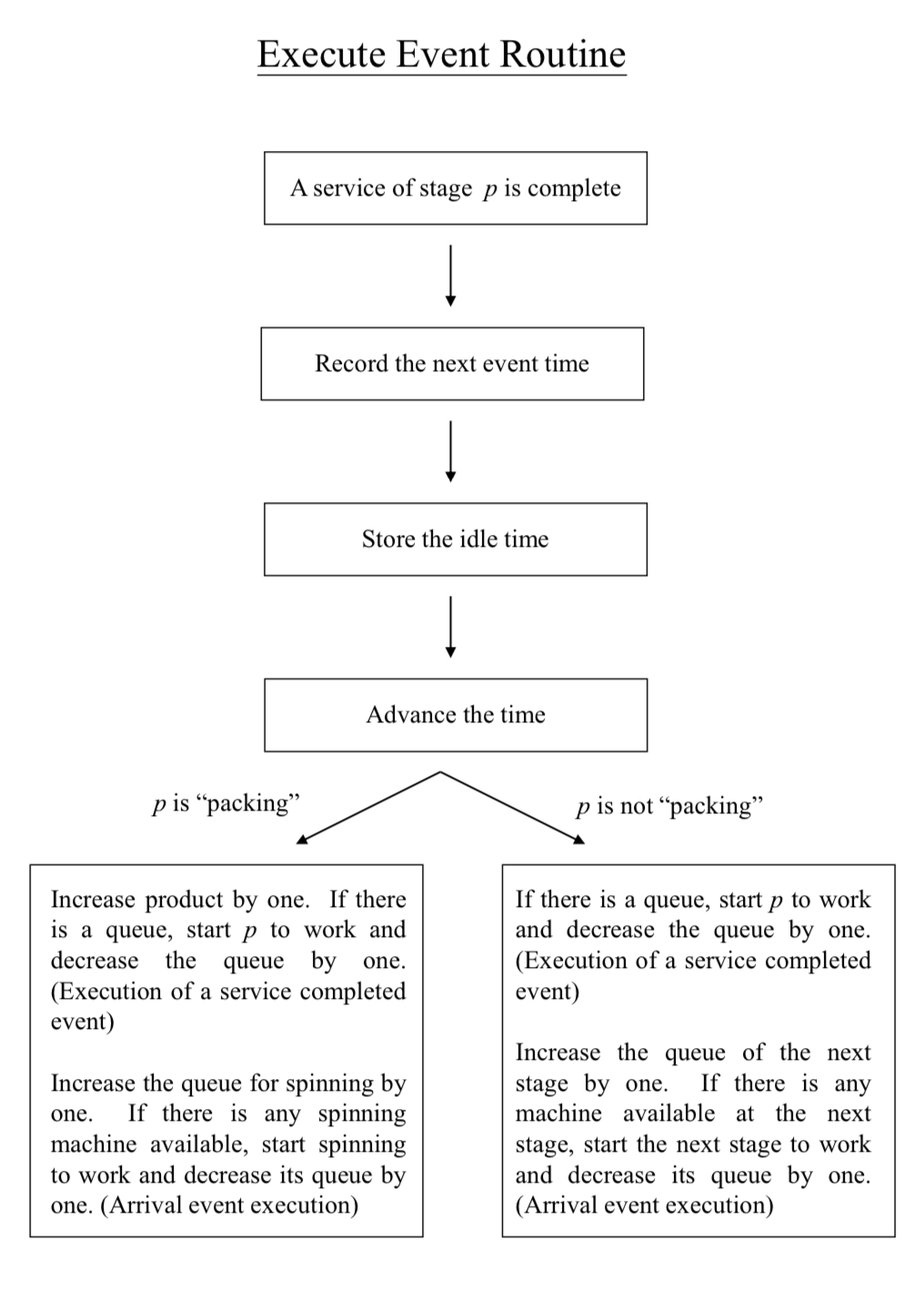

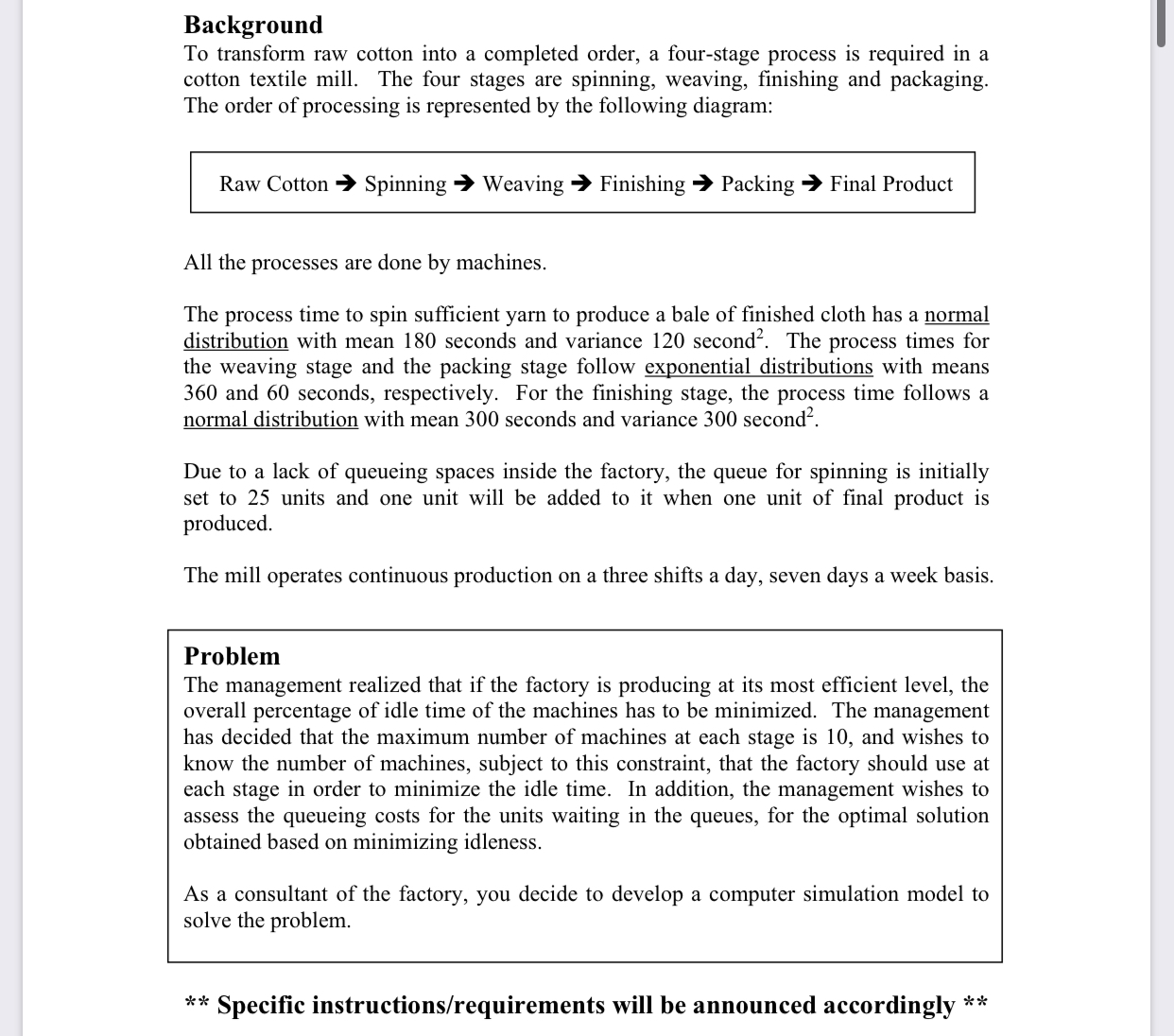

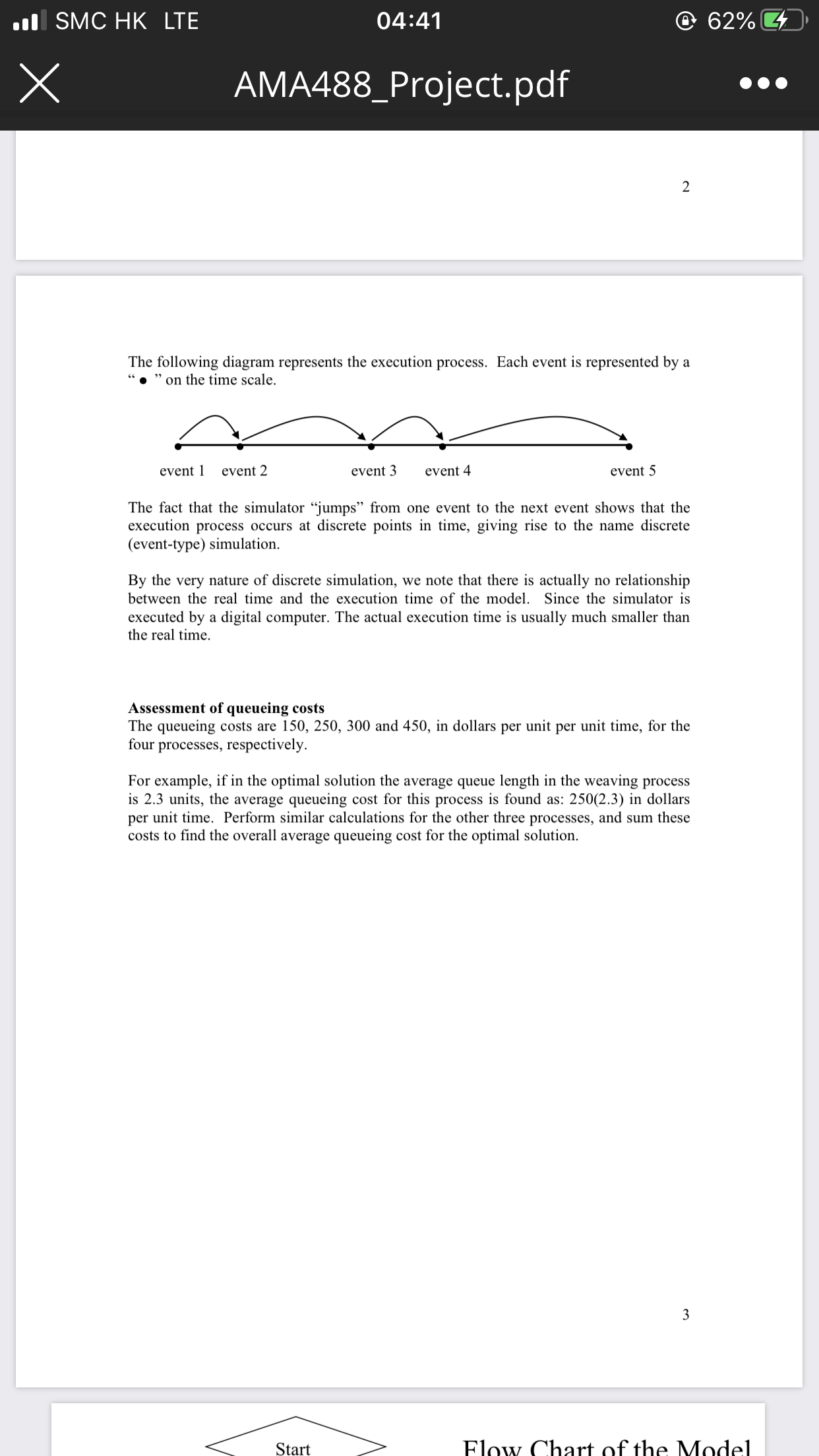

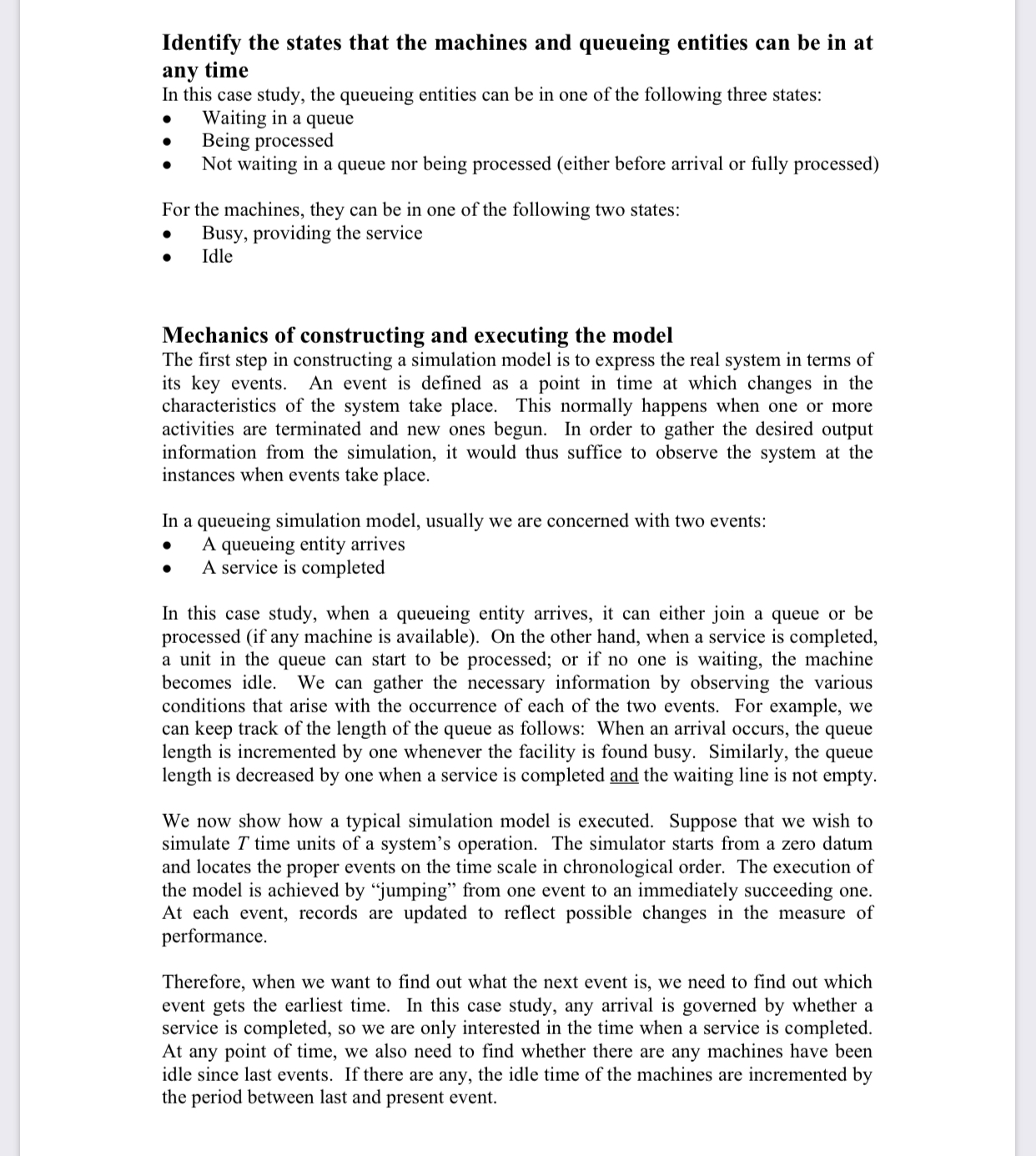

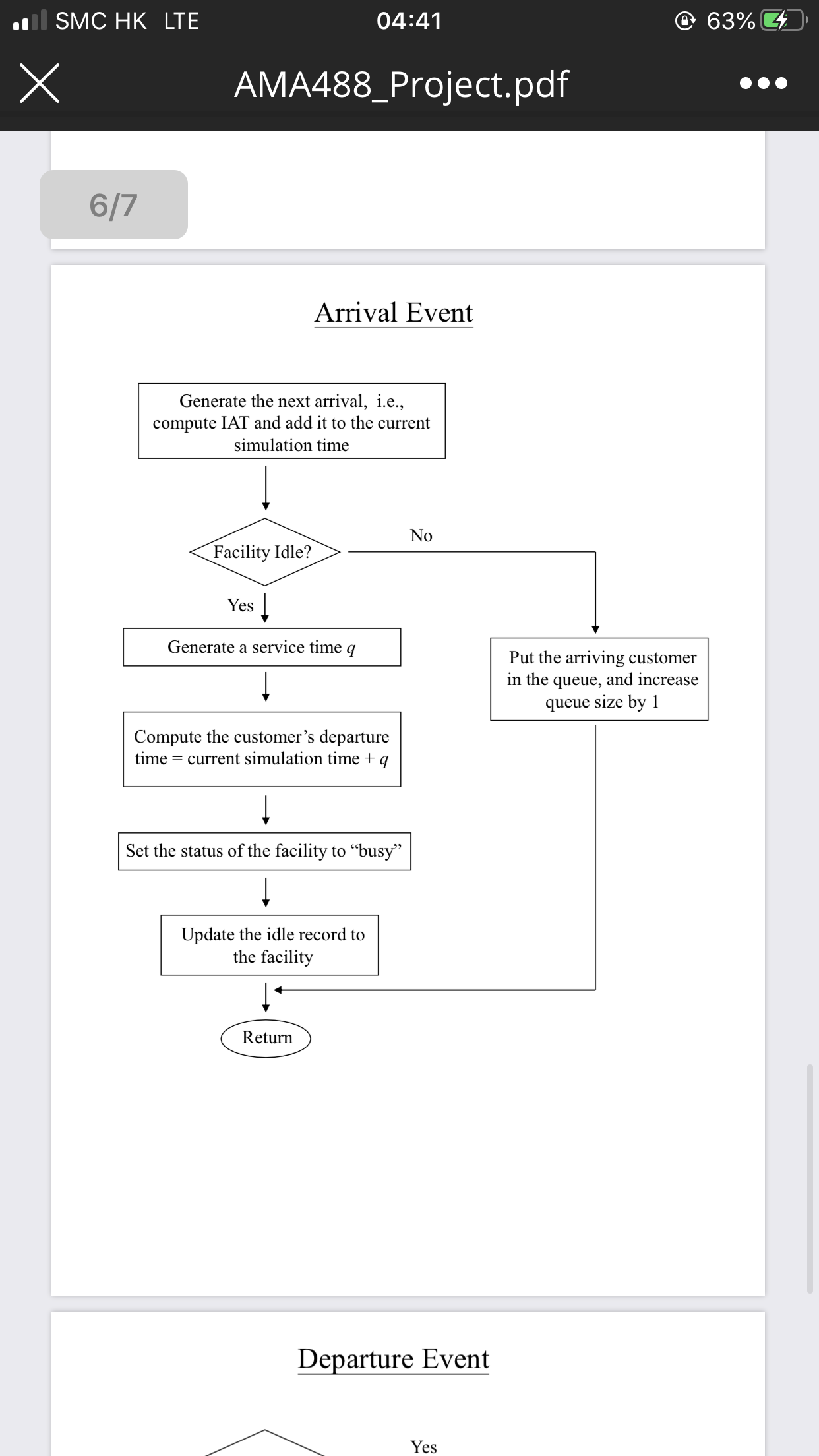

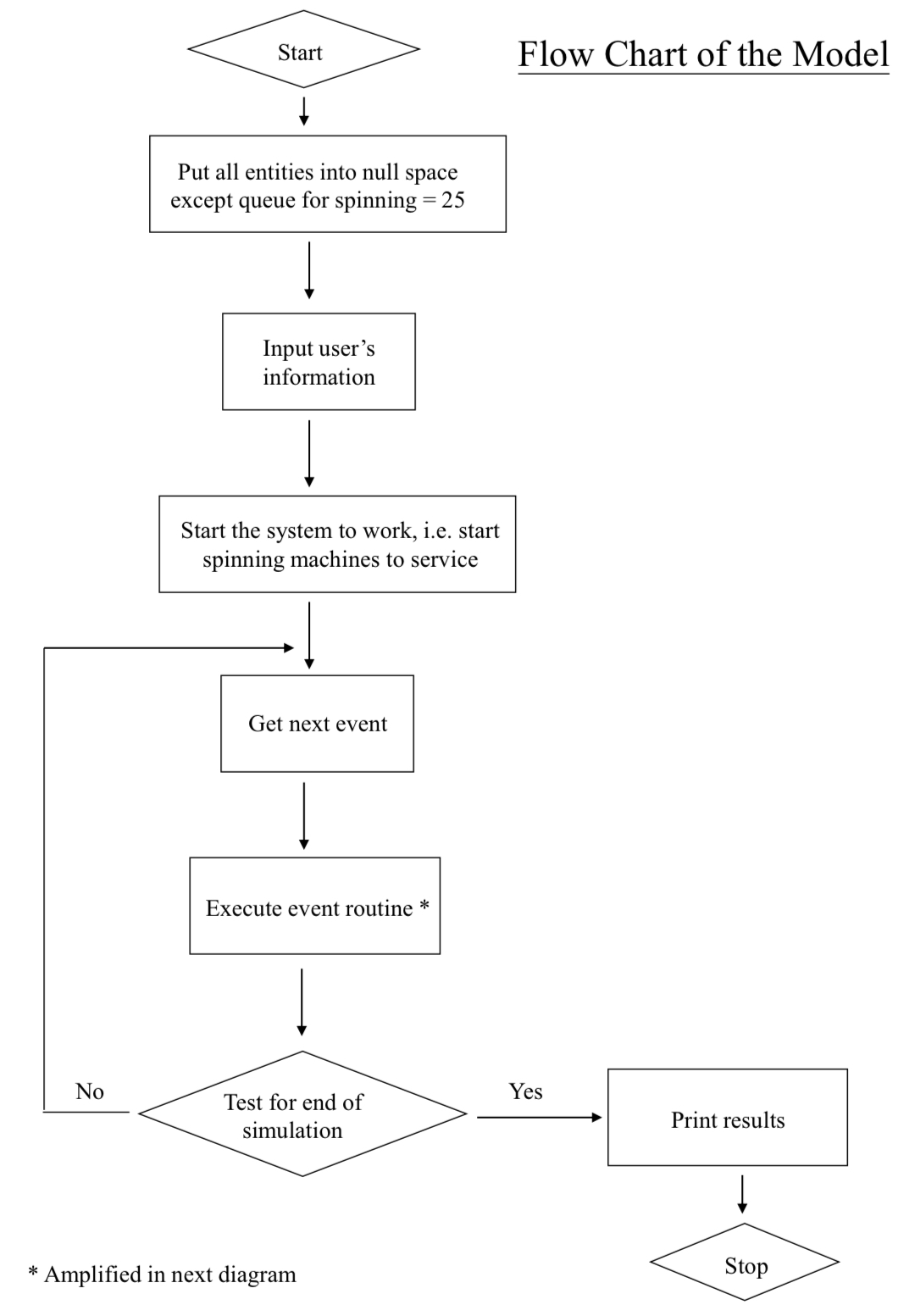

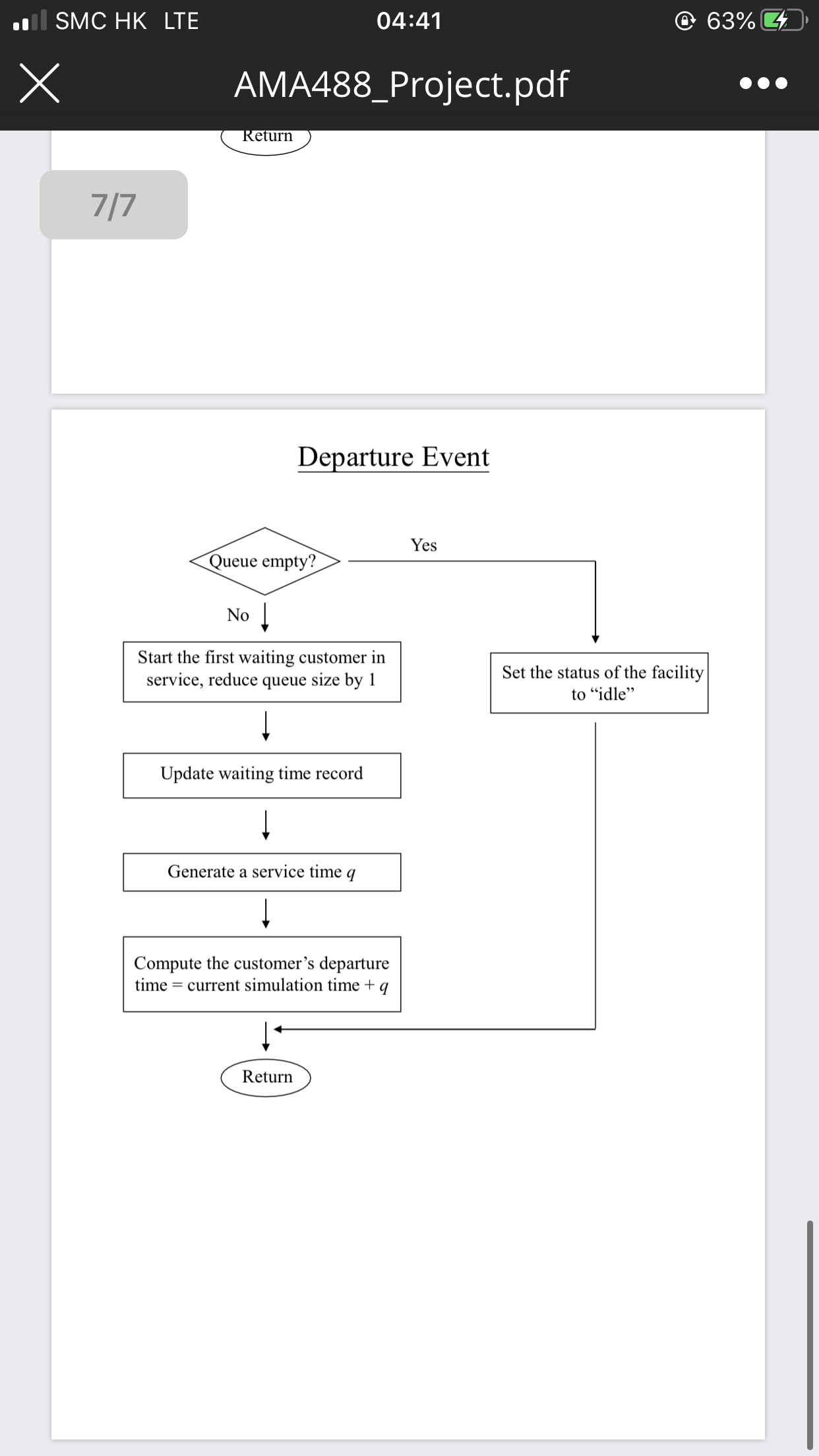

Execute Event Routine A service of stage p is complete Record the next event time Store the idle time Advance the time ! p is \"packing' Increase product by one. If there is a queue, start p to work and decrease the queue by one. (Execution of a service completed event) Increase the queue for spinning by one. If there is any spinning machine available, start spinning to work and decrease its queue by one. (Arrival event execution) > p is not \"packing\" If there is a queue, start p to work and decrease the queue by one. (Execution of a service completed event) Increase the queue of the next stage by one. If there is any machine available at the next stage, start the next stage to work and decrease its queue by one. (Arrival event execution) Background To transform raw cotton into a completed order, a four-stage process is required in a cotton textile mill. The four stages are spinning, weaving, finishing and packaging. The order of processing is represented by the following diagram: Raw Cotton > Spinning > Weaving > Finishing > Packing > Final Product All the processes are done by machines. The process time to spin sufficient yarn to produce a bale of finished cloth has a normal distribution with mean 180 seconds and variance 120 second". The process times for the weaving stage and the packing stage follow exponential distributions with means 360 and 60 seconds, respectively. For the finishing stage, the process time follows a normal distribution with mean 300 seconds and variance 300 second-. Due to a lack of queueing spaces inside the factory, the queue for spinning is initially set to 25 units and one unit will be added to it when one unit of final product is produced. The mill operates continuous production on a three shifts a day, seven days a week basis. Problem The management realized that if the factory is producing at its most efficient level, the overall percentage of idle time of the machines has to be minimized. The management has decided that the maximum number of machines at each stage is 10, and wishes to know the number of machines, subject to this constraint, that the factory should use at each stage in order to minimize the idle time. In addition, the management wishes to assess the queueing costs for the units waiting in the queues, for the optimal solution obtained based on minimizing idleness. As a consultant of the factory, you decide to develop a computer simulation model to solve the problem. ** Specific instructions/requirements will be announced accordingly **.ul SMC HK LTE 04:41 >