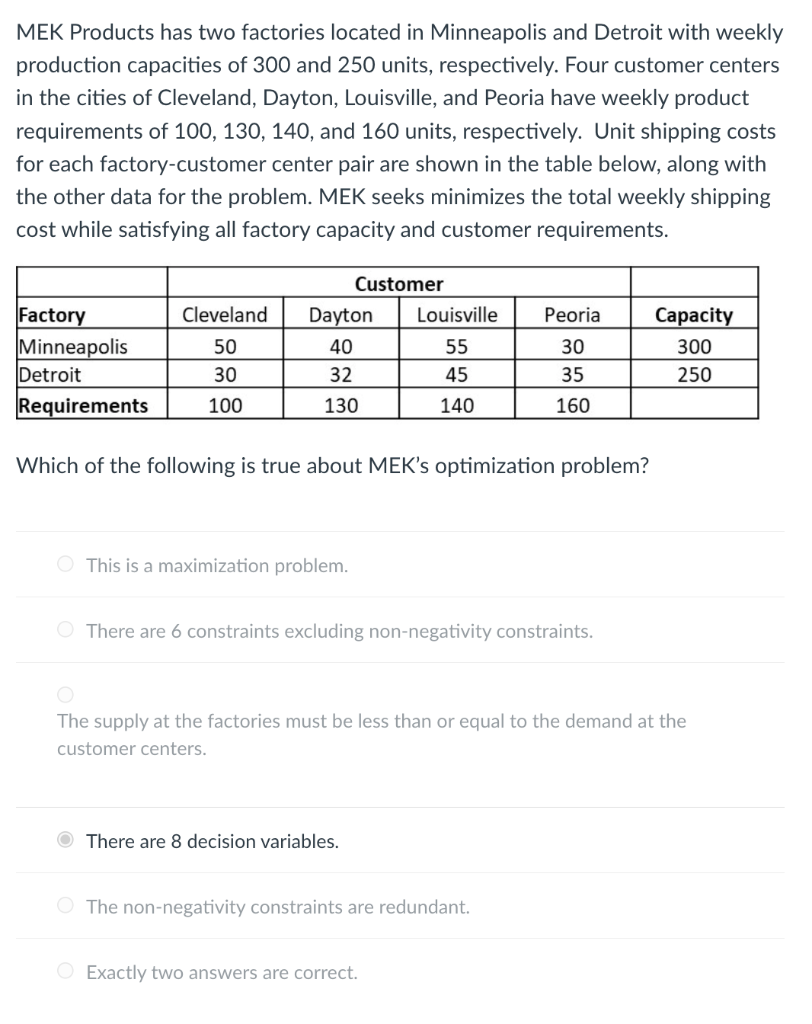

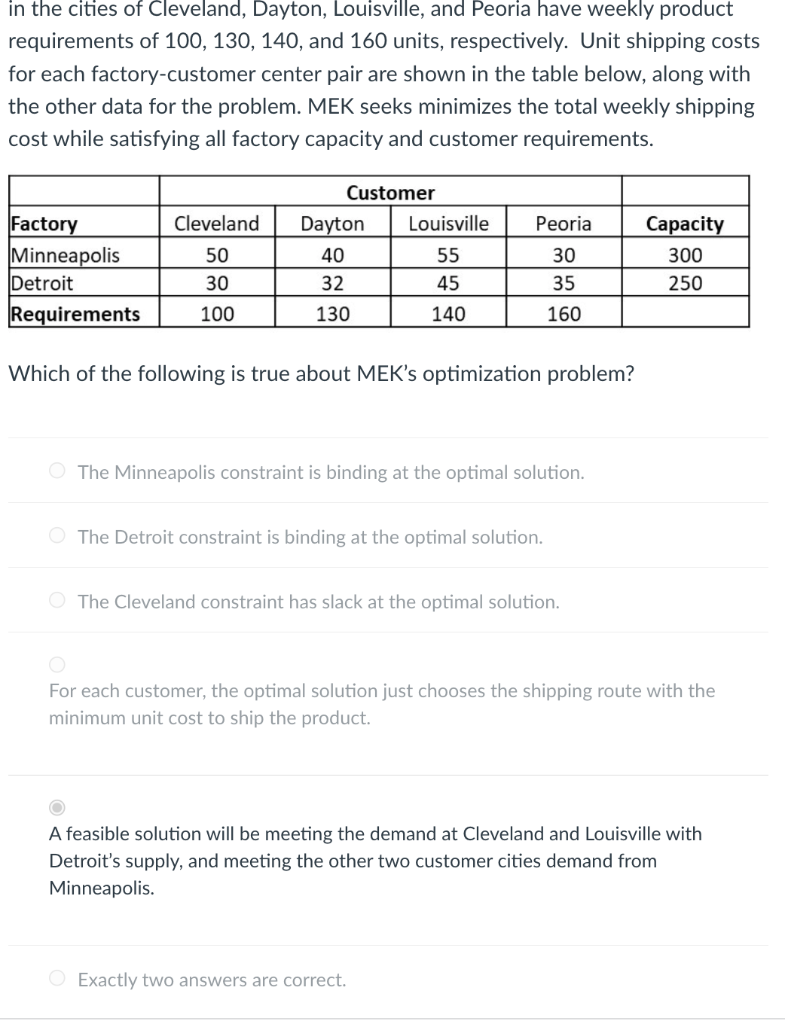

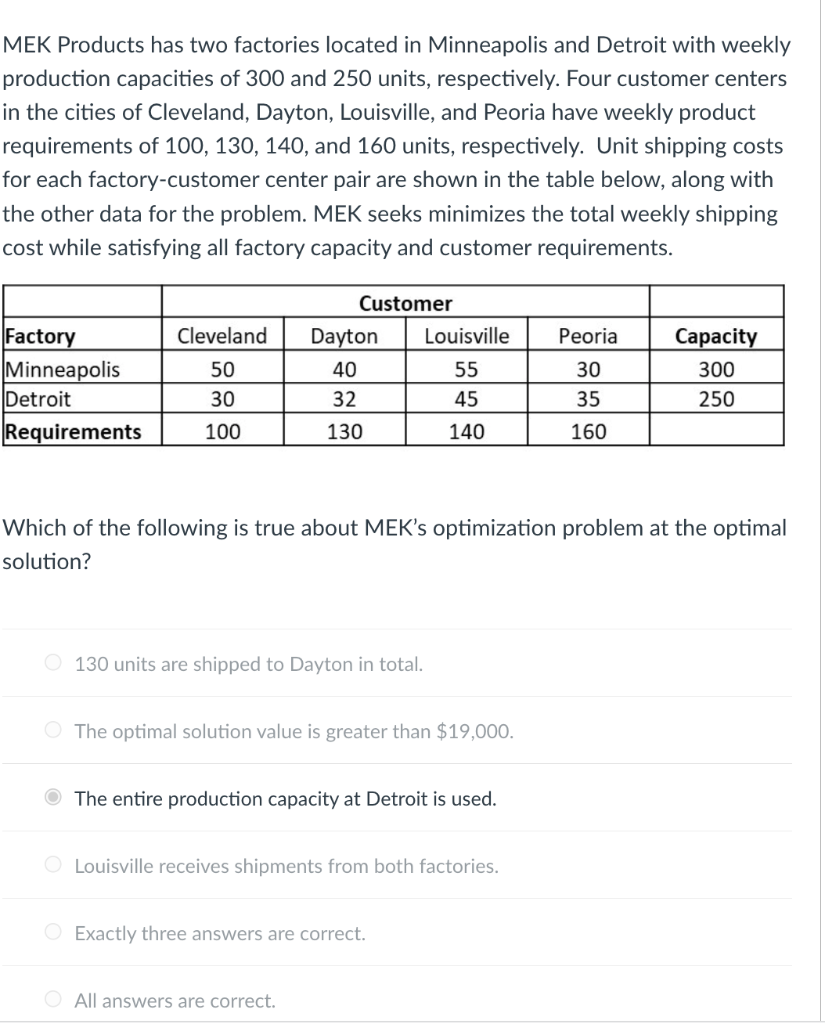

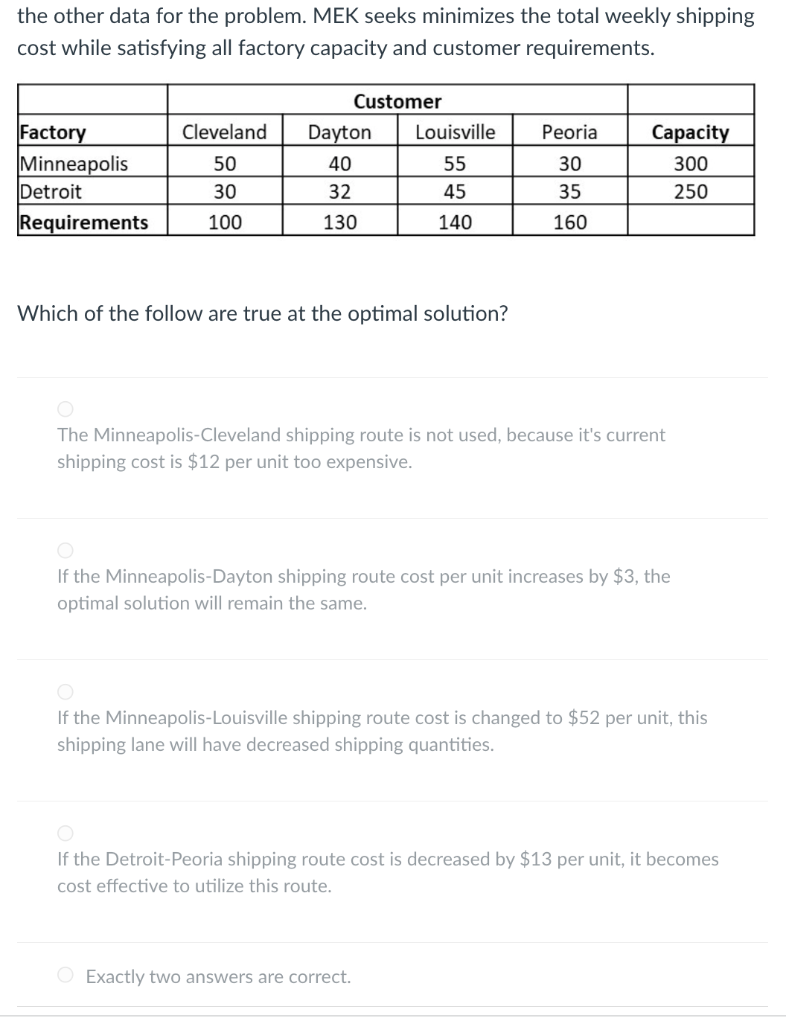

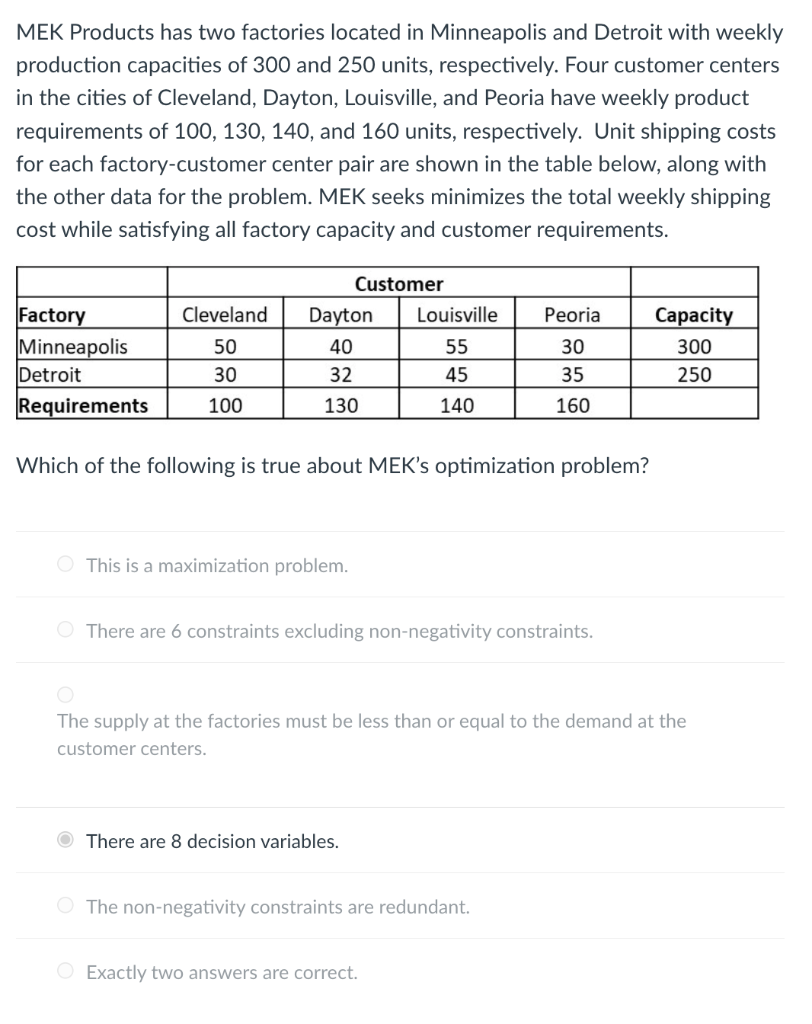

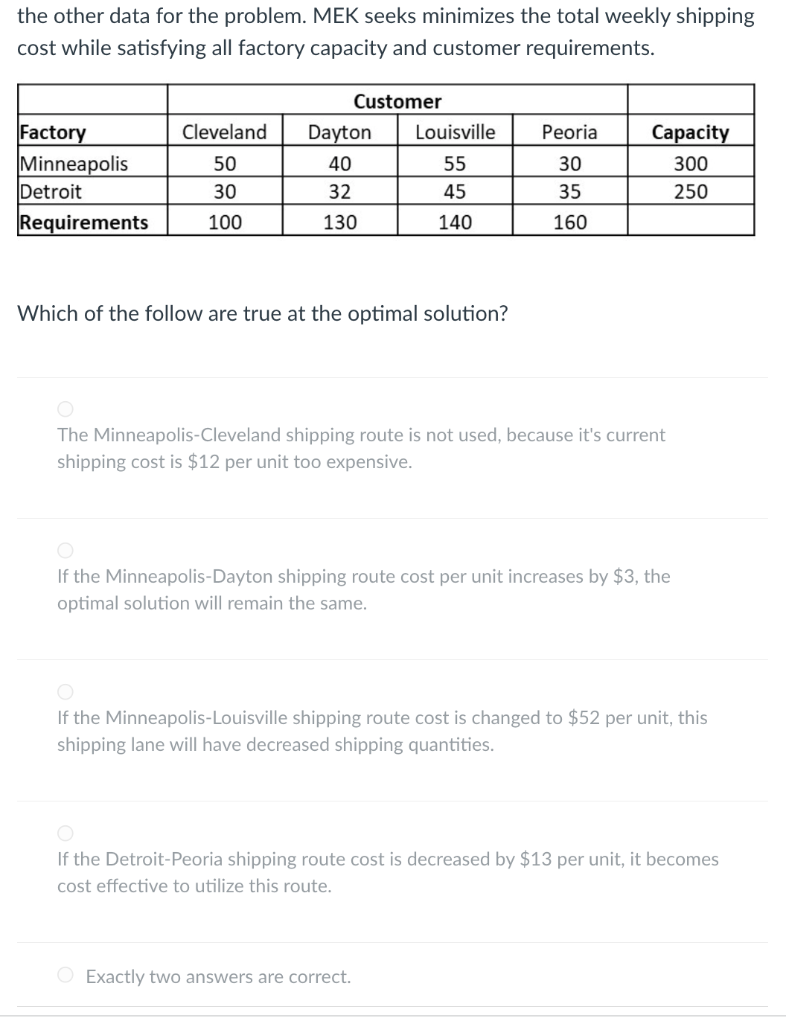

MEK Products has two factories located in Minneapolis and Detroit with weekly production capacities of 300 and 250 units, respectively. Four customer centers in the cities of Cleveland, Dayton, Louisville, and Peoria have weekly product requirements of 100,130,140, and 160 units, respectively. Unit shipping costs for each factory-customer center pair are shown in the table below, along with the other data for the problem. MEK seeks minimizes the total weekly shipping cost while satisfying all factory capacity and customer requirements. Which of the following is true about MEK's optimization problem? This is a maximization problem. There are 6 constraints excluding non-negativity constraints. The supply at the factories must be less than or equal to the demand at the customer centers. There are 8 decision variables. The non-negativity constraints are redundant. Exactly two answers are correct. in the cities of Cleveland, Dayton, Louisville, and Peoria have weekly product requirements of 100,130,140, and 160 units, respectively. Unit shipping costs for each factory-customer center pair are shown in the table below, along with the other data for the problem. MEK seeks minimizes the total weekly shipping cost while satisfying all factory capacity and customer requirements. Which of the following is true about MEK's optimization problem? The Minneapolis constraint is binding at the optimal solution. The Detroit constraint is binding at the optimal solution. The Cleveland constraint has slack at the optimal solution. For each customer, the optimal solution just chooses the shipping route with the minimum unit cost to ship the product. A feasible solution will be meeting the demand at Cleveland and Louisville with Detroit's supply, and meeting the other two customer cities demand from Minneapolis. Exactly two answers are correct. MEK Products has two factories located in Minneapolis and Detroit with weekly production capacities of 300 and 250 units, respectively. Four customer centers in the cities of Cleveland, Dayton, Louisville, and Peoria have weekly product requirements of 100,130,140, and 160 units, respectively. Unit shipping costs for each factory-customer center pair are shown in the table below, along with the other data for the problem. MEK seeks minimizes the total weekly shipping cost while satisfying all factory capacity and customer requirements. Which of the following is true about MEK's optimization problem at the optimal solution? 130 units are shipped to Dayton in total. The optimal solution value is greater than $19,000. The entire production capacity at Detroit is used. Louisville receives shipments from both factories. Exactly three answers are correct. All answers are correct. the other data for the problem. MEK seeks minimizes the total weekly shipping cost while satisfying all factory capacity and customer requirements. Which of the follow are true at the optimal solution? The Minneapolis-Cleveland shipping route is not used, because it's current shipping cost is $12 per unit too expensive. If the Minneapolis-Dayton shipping route cost per unit increases by $3, the optimal solution will remain the same. If the Minneapolis-Louisville shipping route cost is changed to $52 per unit, this shipping lane will have decreased shipping quantities. If the Detroit-Peoria shipping route cost is decreased by $13 per unit, it becomes cost effective to utilize this route. Exactly two answers are correct