Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Background: Bottom bracket (BB) shells (figures 1 and 2) are a key component of bike frames and are relatively easy to make, depending on

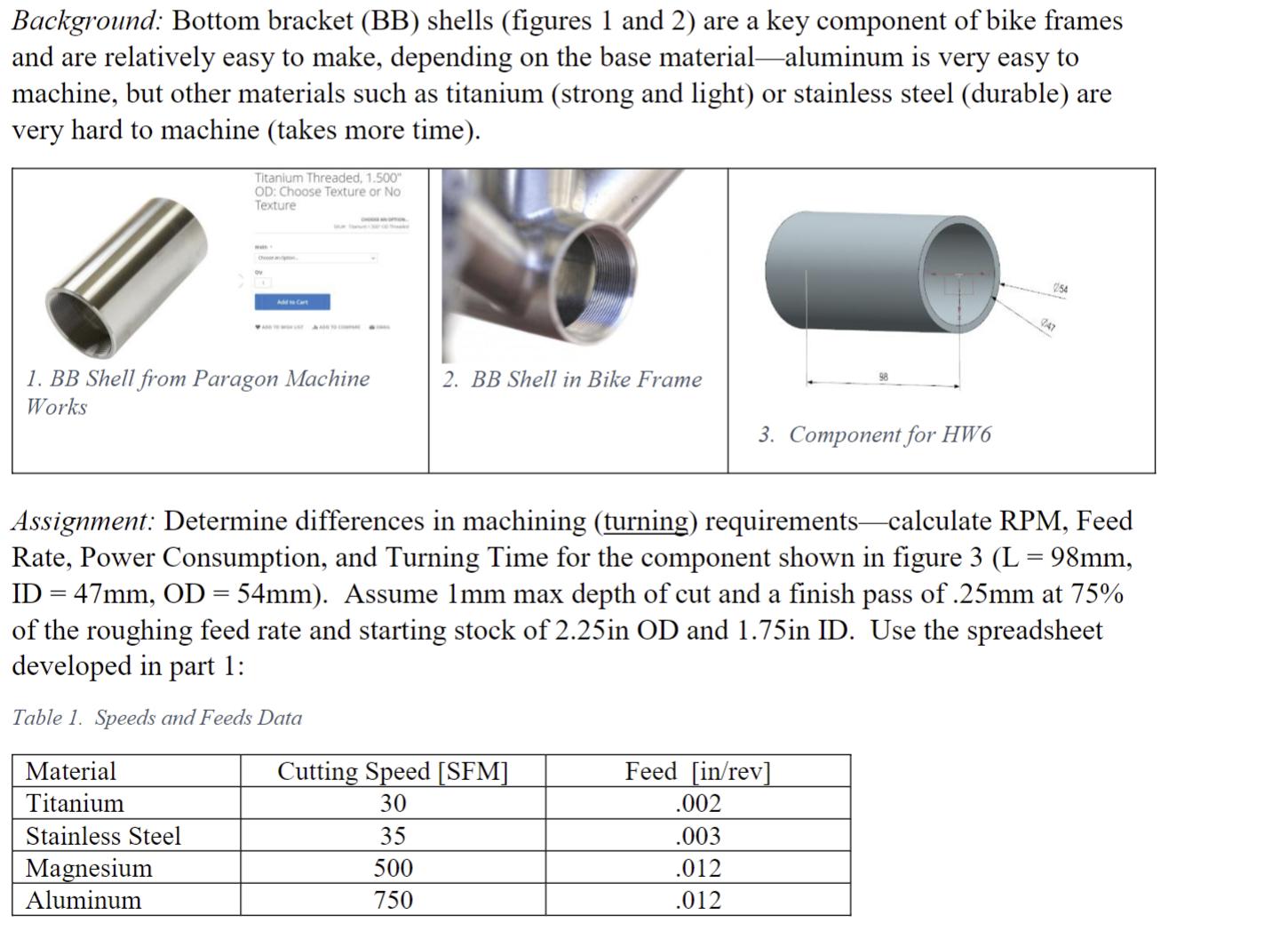

Background: Bottom bracket (BB) shells (figures 1 and 2) are a key component of bike frames and are relatively easy to make, depending on the base material aluminum is very easy to machine, but other materials such as titanium (strong and light) or stainless steel (durable) are very hard to machine (takes more time). Titanium Threaded, 1.500" OD: Choose Texture or No Texture 1. BB Shell from Paragon Machine Works Material Titanium Stainless Steel Add to Cart Magnesium Aluminum 2. BB Shell in Bike Frame Assignment: Determine differences in machining (turning) requirements calculate RPM, Feed Rate, Power Consumption, and Turning Time for the component shown in figure 3 (L = 98mm, ID = 47mm, OD = 54mm). Assume 1 mm max depth of cut and a finish pass of .25mm at 75% of the roughing feed rate and starting stock of 2.25in OD and 1.75in ID. Use the spreadsheet developed in part 1: Table 1. Speeds and Feeds Data 3. Component for HW6 Cutting Speed [SFM] 30 35 500 750 947 Feed [in/rev] .002 .003 .012 .012

Step by Step Solution

★★★★★

3.44 Rating (157 Votes )

There are 3 Steps involved in it

Step: 1

Solution 1 Alejandros minimum RRIF withdrawal requirement for 2028 is 14250 This is calculated by di...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started