Answered step by step

Verified Expert Solution

Question

1 Approved Answer

MGX 3771 Operations Management Individual Assignment 1 (40 marks) Due date: 1 September 2023 at 11.55 PM (Melbourne Local Time) Word limit: 2,400 words

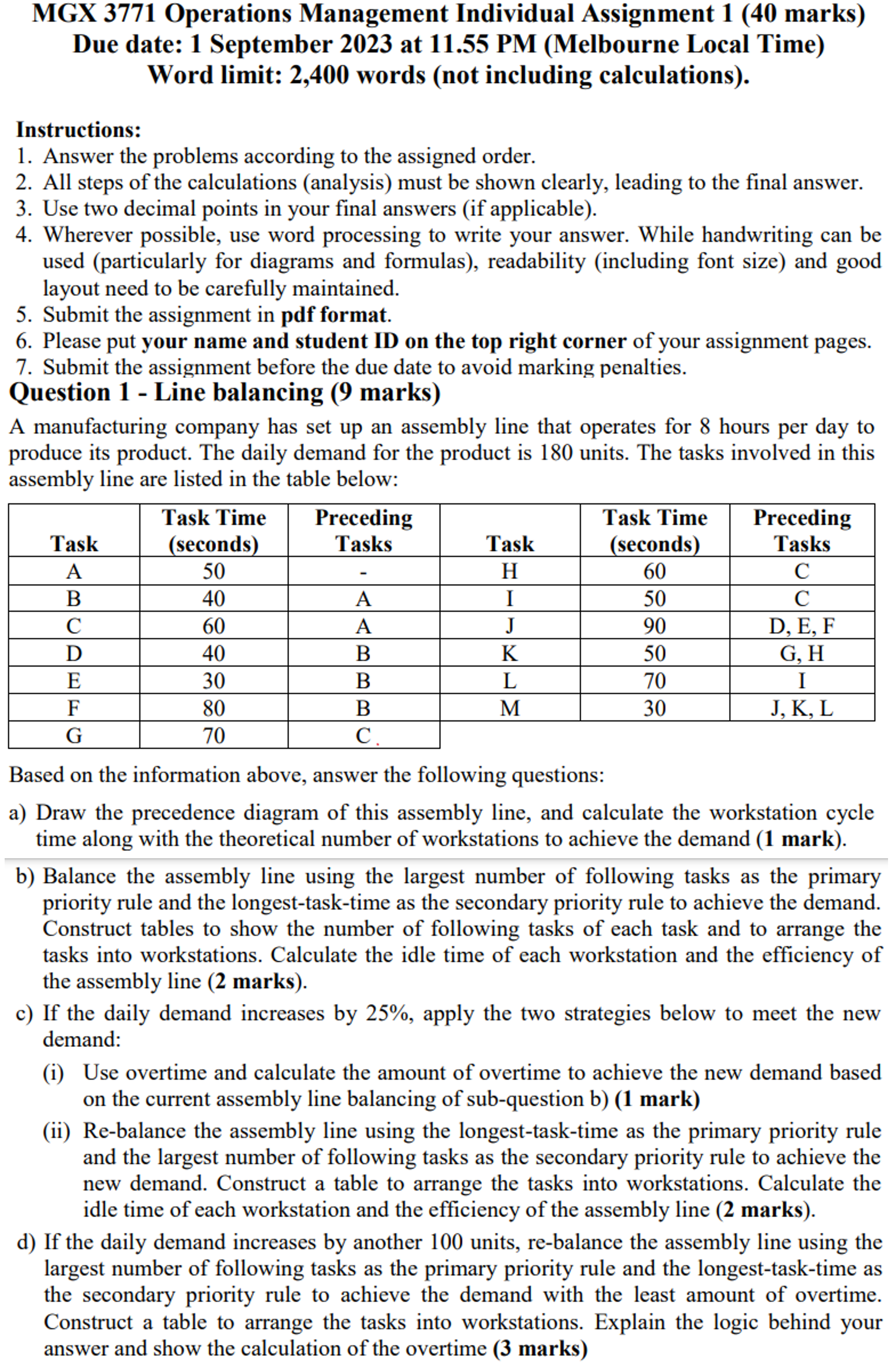

MGX 3771 Operations Management Individual Assignment 1 (40 marks) Due date: 1 September 2023 at 11.55 PM (Melbourne Local Time) Word limit: 2,400 words (not including calculations). Instructions: 1. Answer the problems according to the assigned order. 2. All steps of the calculations (analysis) must be shown clearly, leading to the final answer. 3. Use two decimal points in your final answers (if applicable). 4. Wherever possible, use word processing to write your answer. While handwriting can be used (particularly for diagrams and formulas), readability (including font size) and good layout need to be carefully maintained. 5. Submit the assignment in pdf format. 6. Please put your name and student ID on the top right corner of your assignment pages. 7. Submit the assignment before the due date to avoid marking penalties. Question 1 - Line balancing (9 marks) A manufacturing company has set up an assembly line that operates for 8 hours per day to produce its product. The daily demand for the product is 180 units. The tasks involved in this assembly line are listed in the table below: Task Time (seconds) 50 40 60 40 30 80 70 Task A B C D E F G Preceding Tasks A A B B B C. Task H I J K L M Task Time (seconds) 60 50 90 50 70 30 Preceding Tasks C C D, E, F G, H I J, K, L Based on the information above, answer the following questions: a) Draw the precedence diagram of this assembly line, and calculate the workstation cycle time along with the theoretical number of workstations to achieve the demand (1 mark). b) Balance the assembly line using the largest number of following tasks as the primary priority rule and the longest-task-time as the secondary priority rule to achieve the demand. Construct tables to show the number of following tasks of each task and to arrange the tasks into workstations. Calculate the idle time of each workstation and the efficiency of the assembly line (2 marks). c) If the daily demand increases by 25%, apply the two strategies below to meet the new demand: (i) Use overtime and calculate the amount of overtime to achieve the new demand based on the current assembly line balancing of sub-question b) (1 mark) (ii) Re-balance the assembly line using the longest-task-time as the primary priority rule and the largest number of following tasks as the secondary priority rule to achieve the new demand. Construct a table to arrange the tasks into workstations. Calculate the idle time of each workstation and the efficiency of the assembly line (2 marks). d) If the daily demand increases by another 100 units, re-balance the assembly line using the largest number of following tasks as the primary priority rule and the longest-task-time as the secondary priority rule to achieve the demand with the least amount of overtime. Construct a table to arrange the tasks into workstations. Explain the logic behind your answer and show the calculation of the overtime (3 marks)

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started