Answered step by step

Verified Expert Solution

Question

1 Approved Answer

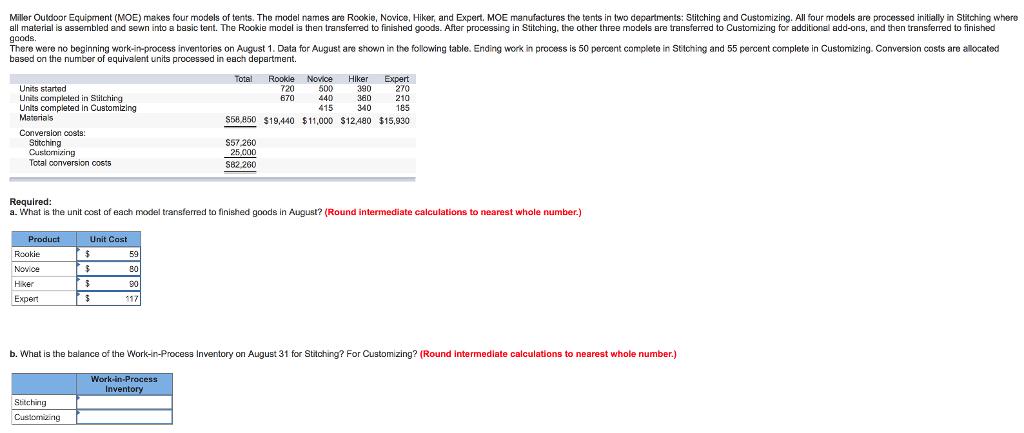

Miller Outdoor Equipment (MOE) makes four models of tents. The model names are Rookie, Novice, Hiker, and Expert. MOE manufactures the tents in two

Miller Outdoor Equipment (MOE) makes four models of tents. The model names are Rookie, Novice, Hiker, and Expert. MOE manufactures the tents in two departments: Stitching and Customizing. All four models are processed initially in Stitching where all material is assembled and sewn into a basic tent. The Rookie model is then transferred to finished goods. After processing in Stitching, the other three models are transferred to Customizing for additional add-ons, and then transferred to finished goods. There were no beginning work-in-process inventories on August 1. Data for August are shown in the following table. Ending work in process is 50 percent complete in Silching and 55 percent complete in Customizing. Conversion costs are allocated based on the number of equivalent units processed in each department. Rookle Novice 720 Total Hiker 390 Expert 270 Units started 500 Units completed in Stilching Units completed in Customizing Materials 670 440 360 210 415 340 185 $58,850 $19,440 $11,000 $12480 $15,930 Converalon costs: Stitching Customizing Total conversion costs S57,260 25,000 S82,260 Required: a. What is the unit cost of each model transferred to finished goods in August? (Round intermediate calculations to nearest whole number.) Product Unit Cast Rookie 59 Novice 80 Hiker 90 xpert 117 b. What is the balance of the Work-in-Process Inventory on August 31 for Stitching? For Customizing? (Round intermediate calculations to nearest whole number.) Work-in-Process Inventory Stitching Customizing

Step by Step Solution

★★★★★

3.34 Rating (151 Votes )

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started