Question

Module learning outcomes to be assessed: Analyse supply chain performance; Design logistics networks including transportation modes; Analyse advanced forecasting techniques in the planning and control

| Module learning outcomes to be assessed:

|

| AIMS To further develop students analytical skills on logistics planning and control functions, including Enterprise Resource Planning (ERP) System. |

| OBJECTIVES

|

| SUBMISSION REQUIREMENTS One report, maximum of 2000 words, covering:

Task 1) What problem became evident to Harish? Calculate the MRP to find this out. You must use the MRP table format that was used in the tutorials otherwise it would not be marked. Task 2) What should be the action? Provide evidence for your answer? Task 3) What are the likely difficulties that Farnray will face if they continue to use their existing system of calculating material requirements?

Your boss wants you to use the data provided in Table 27.5 to create the SPADE as a new product in SAP Business ByDesign. You MUST follow the instruction shown in Table 5 about the Product ID which is highlighted in RED font. After creating the product successfully, you are required to snap shots the SAP Business ByDesign screens for the SPADE product after creation (at least 4 screen shots are required). Your product will be checked also on the system to validate your answer for this submission requirements.

|

Table 27.5. SPADE 289 SAP entry data to create the product in SAP Business ByDesign

| Product ID: P_SPADE_23_GID Where GID is your group ID number Example1: if your group number is 9 so your product ID must be P_SPADE_23_G009 Example2: if your group number is 99 so your product ID must be P_SPADE_23_G099 Example3: if your group number is 101 so your product ID must be P_SPADE_23_G101 | |

|

Part Description and Part Number |

SPADE 289

|

|

Net weight |

3 kg |

|

Gross weight |

3.2kg |

|

Net volume |

300 L |

|

Gross volume |

320 L |

|

Site |

Almika Branch1 |

|

Planning Area |

Almika Heating Cleveland |

|

Availability check horizon |

14 days |

|

Sale |

Direct sale |

|

Status of the product |

Finished product, cost $300 |

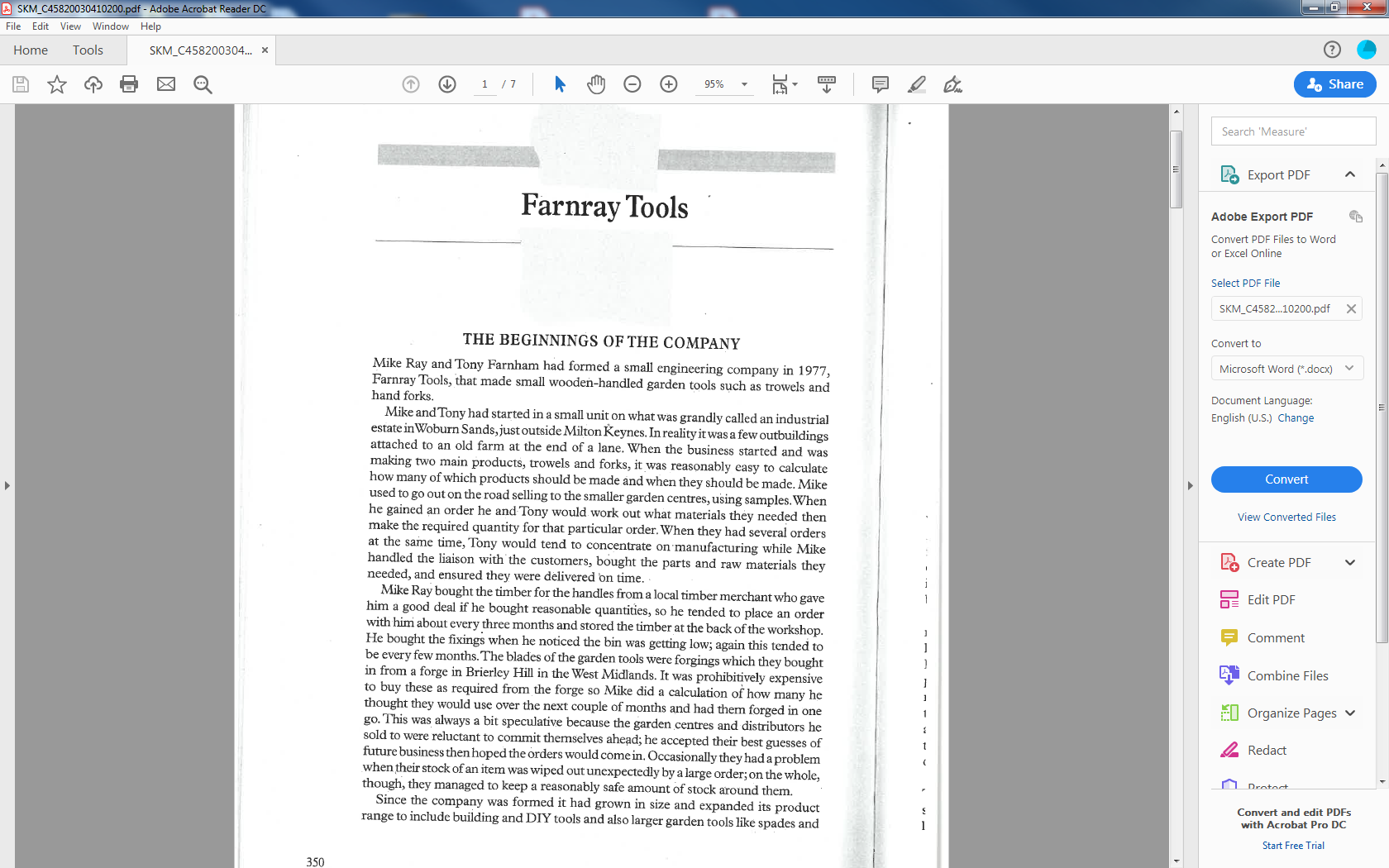

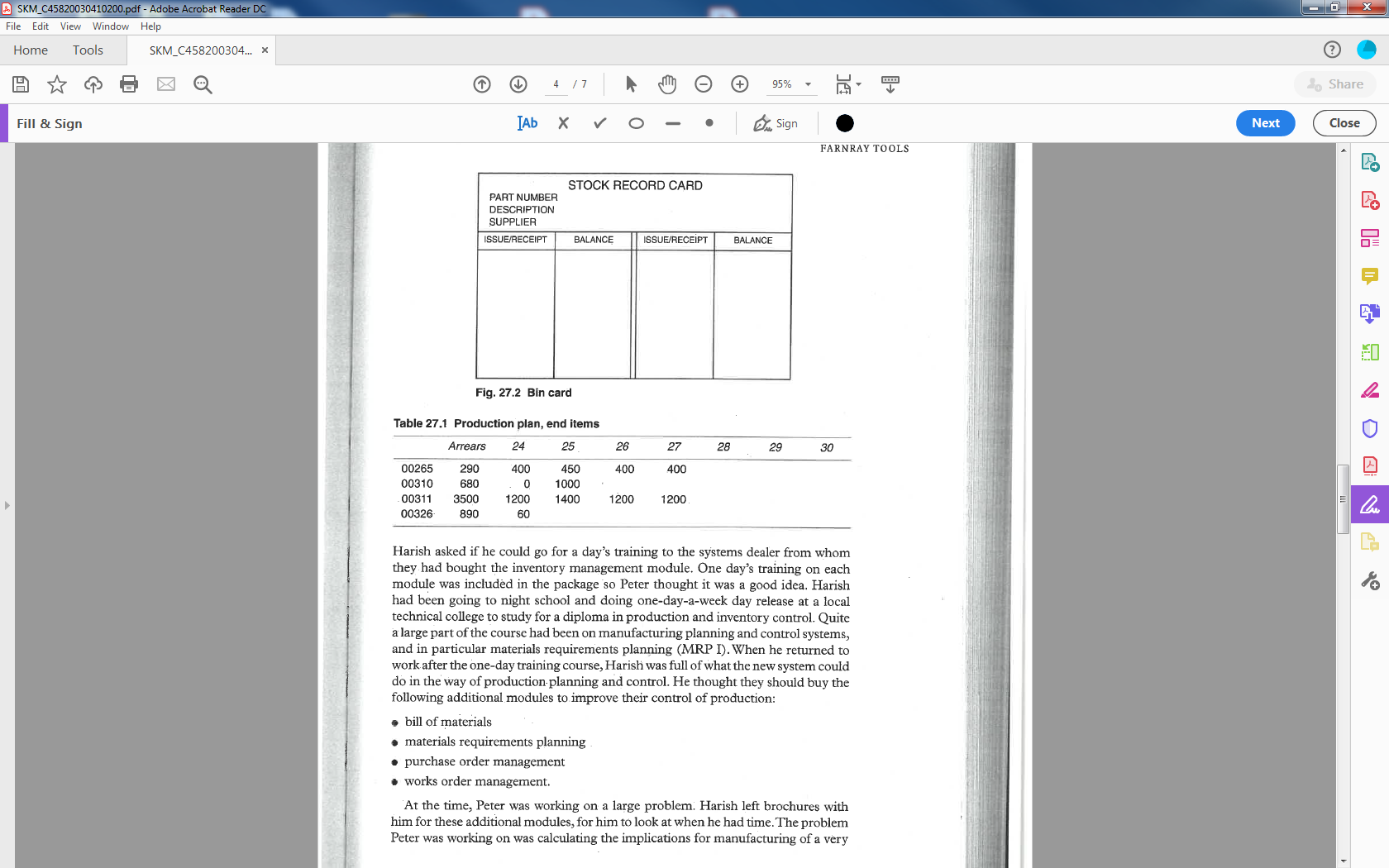

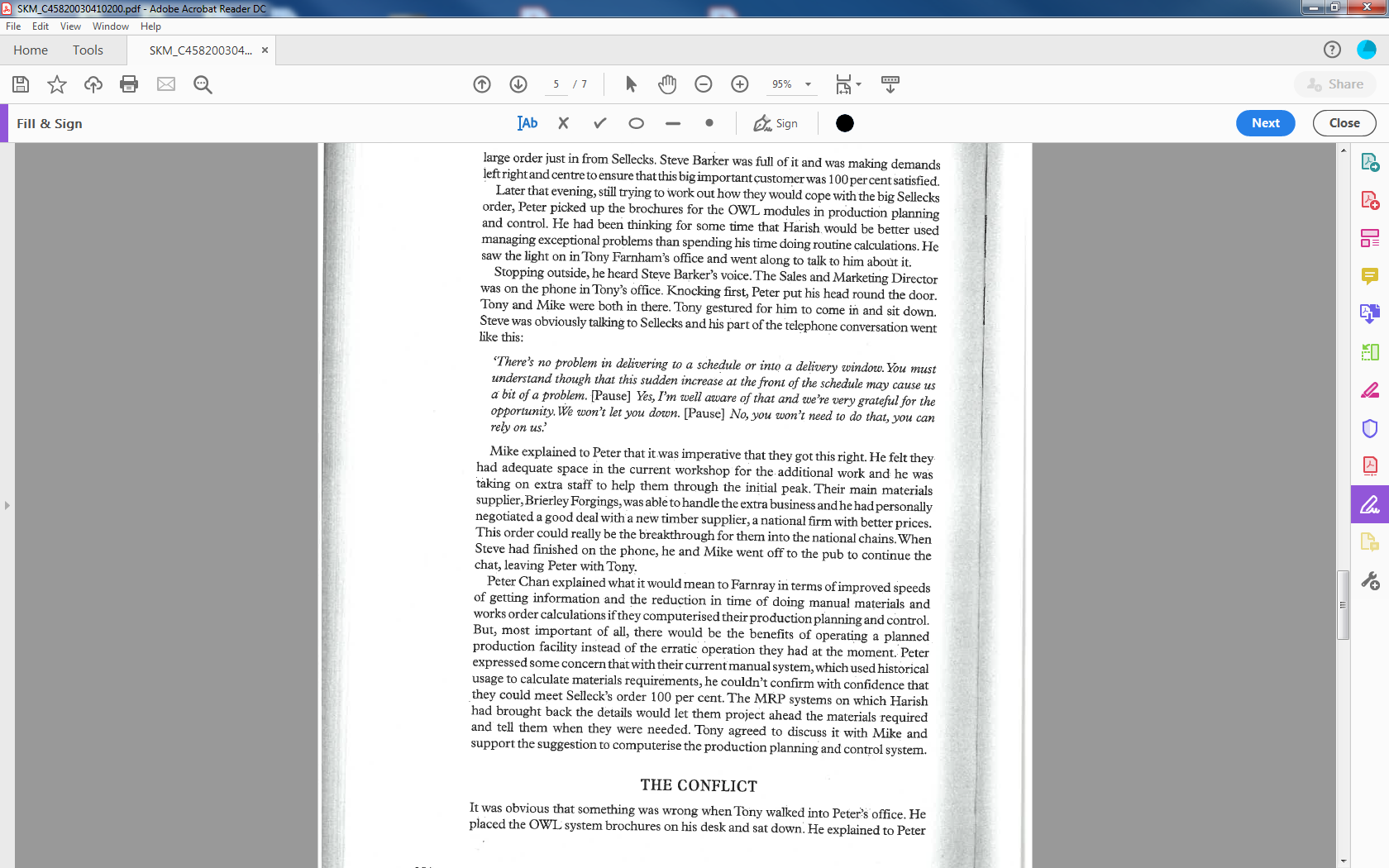

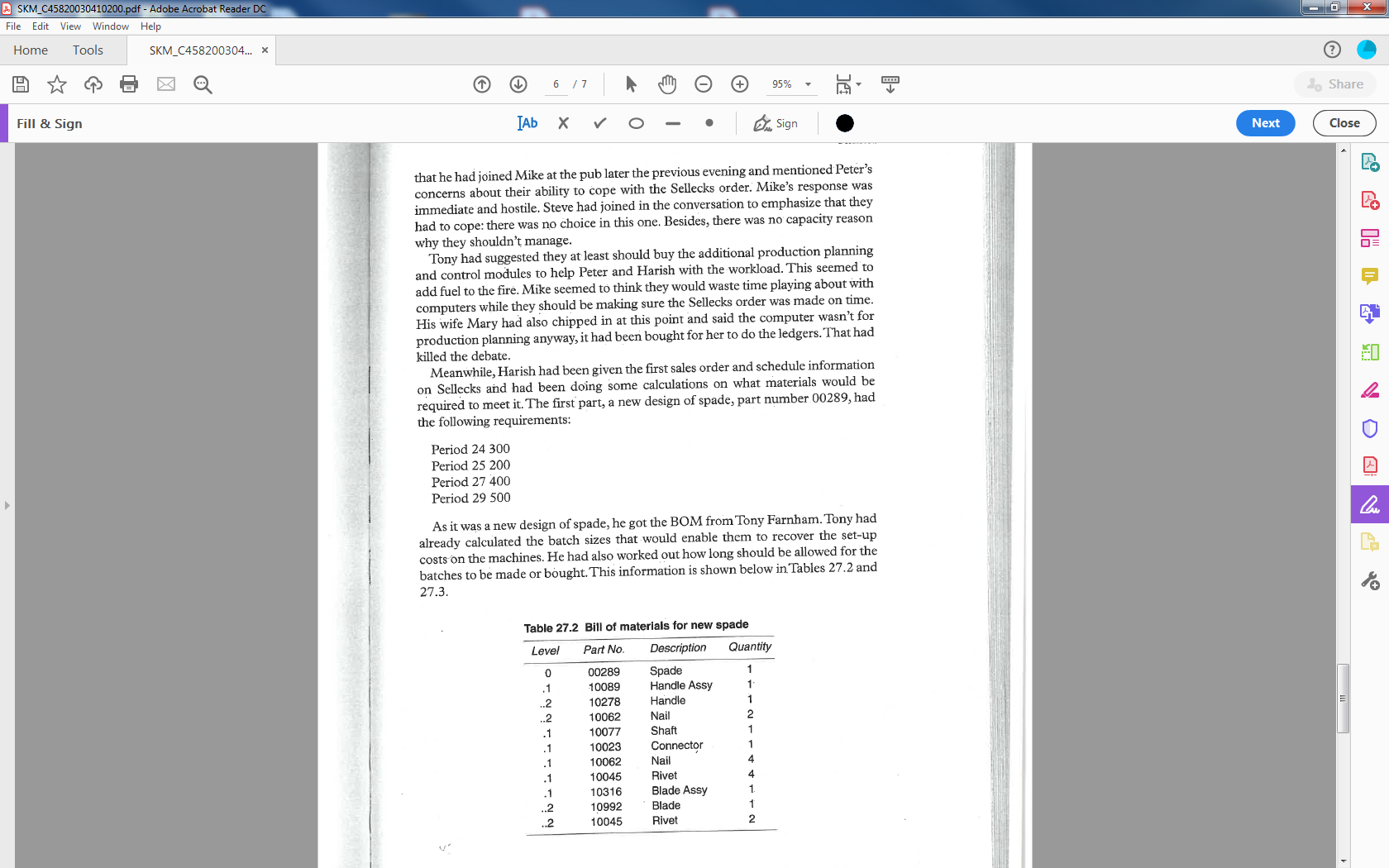

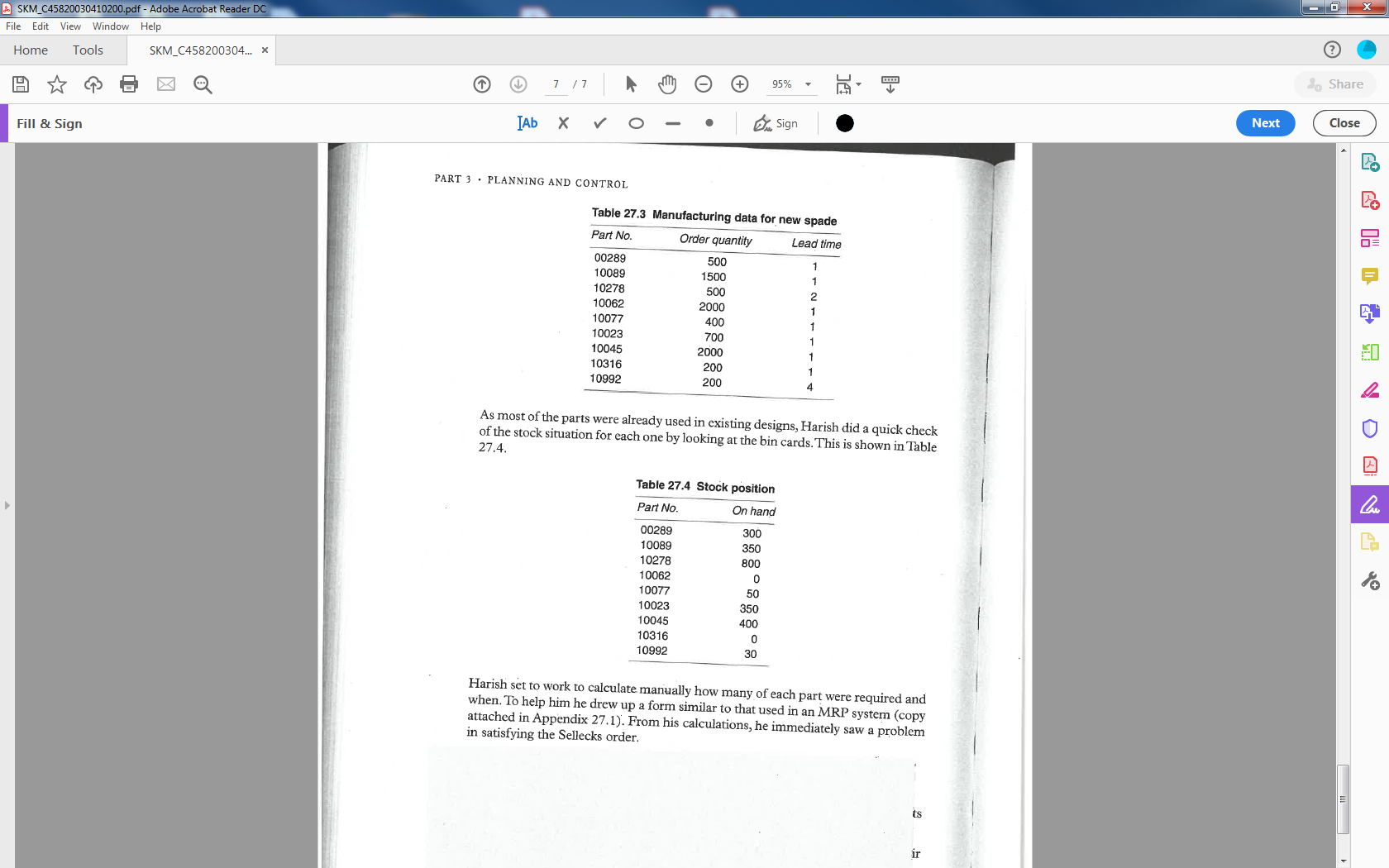

THE BEGINNINGS OF THE COMPANY Mike Ray and Tony Farnham had formed a small engineering company in 1977, Farnray Tools, that made small wooden-handled garden tools such as trowels and hand forks. Mike and Tony had started in a small unit on what was grandly called an industrial estate inWoburn Sands, just outside Milton K Keynes. In reality it was a few outbuildings attached to an old farm at the end of a lane. When the business started and was making two main products, trowels and forks, it was reasonably easy to calculate how many of which products should be made and when they should be made. Mike used to go out on the road selling to the smaller garden centres, using samples. When he gained an order he and Tony would work out what materials they needed then make the required quantity for that particular order. When they had several orders at the same time, Tony would tend to concentrate on manufacturing while Mike handled the liaison with the customers, bought the parts and raw materials they needed, and ensured they were delivered on time. Mike Ray bought the timber for the handles from a local timber merchant who gave him a good deal if he bought reasonable quantities, so he tended to place an order with him about every three months and stored the timber at the back of the workshop. He bought the fixings when he noticed the bin was getting low; again this tended to be every few months. The blades of the garden tools were forgings which they bought in from a forge in Brierley Hill in the West Midlands. It was prohibitively expensive to buy these as required from the forge so Mike did a calculation of how many he thought they would use over the next couple of months and had them forged in one go. This was always a bit speculative because the garden centres and distributors he sold to were reluctant to commit themselves ahead; he accepted their best guesses of future business then hoped the orders would come in. Occasionally they had a problem when their stock of an item was wiped out unexpectedly by a large order; on the whole, though, they managed to keep a reasonably safe amount of stock around them. Since the company was formed it had grown in size and expanded its product range to include building and DIY tools and also larger garden tools like spades and hoes. By 1992, Farnray had a turnover of nearly 2 million and employed 28 people in total, 18 of them direct shop-floor operatives. The roles of the other ten are shown in the organisation chart in Fig. 27.1. Fig. 27.1 Farnray Tools organisation chart Farnray had moved to a newly built industrial estate on the edge of Milton Keynes which had more shop-floor space into which to expand. As the company had grown, Mike's andTony's roles were similar to before; Tony looked after product design, manufacturing and the operations of the business while Mike concentrated on ensuring the customers were satisfied and keeping the company afloat financially. They had found it necessary to bring in a finance director and a sales and marketing director. Mike had brought in his wife, Mary, to help with the book-keeping, payroll and some typing. While everyone in the company respected Mike's selling abilities, he had never managed to sell to the buyers in the centralised purchasing units for the 'sheds' (the large warehouse DIY chains). Steve Barker was recruited as Sales and Marketing Director specifically because of his experience of dealing with these buyers; he had previously been a sales manager for a large power tools manufacturer. Within six months of joining, Steve had managed to get a small order from Sellecks, one of the largest UK DIY superstores, for part of Farnray's range of builder's tools and all of their range of garden tools. It was recognised that this was a trial order and that if they performed well and kept to the delivery schedule there were possibilities of significant orders from them in the future. Sellecks was over twenty times the size of any of Farnray's existing customers. They were a professional organisation who were used to dealing with organised sales departments with good information systems. The systems at Farnray were likely to be somewhat of a shock to them. THE SYSTEMS Farnray's systems were still largely manual and time-consuming to operate. They were also prone to such inaccuracies as misfiled invoices, purchase orders that were placed by telephone and never confirmed in writing and many other irritating occurrences. Mistakes had been made in the past because of this overloaded manual system. Gordon Bowler, the Finance Director, used to be a finance manager at a powder coatings company where he had been responsible for computerising the ledgers, invoicing and payroll of the accounts department. He proposed that they buy a reasonable size PC-based integrated financial system with sales order processing as part of it. Mary Ray had been pushing her husband for some time to computerise the ledgers as the volume of ledger transactions was becoming more than she could handle. After reviewing the available systems with their local dealers, a quick decision was made to buy the following modules from the OWL suite, a business management system: - purchase, sales and nominal ledgers - invoicing - sales order processing - inventory management - job costing payroll. Gordon passed the details of the inventory management module to Peter Chan, the Manufacturing Manager, for implementation. When Peter dropped the details of the inventory management module on the desk of his Production Planner, Harish Patel, it brightened up Harish's day. Up until then, Harish had been manually calculating the purchase requirements for the next three months on all of the 850 parts used in the business. Each week of the month he looked at the records for one-quarter of the parts. For each one he had to check the bin card to see the balance of inventory, look at the usage over the last few months, then place orders to cover them for the next few months, trying to keep a few weeks safety stock as protection. One of the bin cards is shown in Fig. 27.2. Harish's job was quite routine really. On Mondays he issued the production plan for the week and raised all the works orders for the shop-floor. On Tuesdays and Wednesdays he checked inventory and raised purchase orders. On Thursdays he went to college and on Fridays he worked out the following week's production plan, rig. 1,2 Bin cara Table 27.1 Production plan, end items Harish asked if he could go for a day's training to the systems dealer from whom they had bought the inventory management module. One day's training on each module was included in the package so Peter thought it was a good idea. Harish had been going to night school and doing one-day-a-week day release at a local technical college to study for a diploma in production and inventory control. Quite a large part of the course had been on manufacturing planning and control systems, and in particular materials requirements planning (MRP I). When he returned to work after the one-day training course, Harish was full of what the new system could do in the way of production planning and control. He thought they should buy the following additional modules to improve their control of production: - bill of materials - materials requirements planning - purchase order management - works order management. At the time, Peter was working on a large problem. Harish left brochures with him for these additional modules, for him to look at when he had time. The problem Peter was working on was calculating the implications for manufacturing of a very large order just in from Sellecks. Steve Barker was full of it and was making demands left right and centre to ensure that this big important customer was 100 per cent satisfied. Later that evening, still trying to work out how they would cope with the big Sellecks order, Peter picked up the brochures for the OWL modules in production planning and control. He had been thinking for some time that Harish would be better used managing exceptional problems than spending his time doing routine calculations. He saw the light on in Tony Farnham's office and went along to talk to him about it. Stopping outside, he heard Steve Barker's voice. The Sales and Marketing Director was on the phone in Tony's office. Knocking first, Peter put his head round the door. Tony and Mike were both in there. Tony gestured for him to come in and sit down. Steve was obviously talking to Sellecks and his part of the telephone conversation went like this: 'There's no problem in delivering to a schedule or into a delivery window. You must understand though that this sudden increase at the front of the schedule may cause us a bit of a problem. [Pause] Yes, I'm well aware of that and we're very grateful for the opportunity. We won't let you down. [Pause] No, you won't need to do that, you can rely on us.' Mike explained to Peter that it was imperative that they got this right. He felt they. had adequate space in the current workshop for the additional work and he was taking on extra staff to help them through the initial peak. Their main materials supplier, Brierley Forgings, was able to handle the extra business and he had personally negotiated a good deal with a new timber supplier, a national firm with better prices. This order could really be the breakthrough for them into the national chains. When Steve had finished on the phone, he and Mike went off to the pub to continue the chat, leaving Peter with Tony. Peter Chan explained what it would mean to Farnray in terms of improved speeds of getting information and the reduction in time of doing manual materials and works order calculations if they computerised their production planning and control. But, most important of all, there would be the benefits of operating a planned production facility instead of the erratic operation they had at the moment. Peter expressed some concern that with their current manual system, which used historical usage to calculate materials requirements, he couldn't confirm with confidence that they could meet Selleck's order 100 per cent. The MRP systems on which Harish had brought back the details would let them project ahead the materials required and tell them when they were needed. Tony agreed to discuss it with Mike and support the suggestion to computerise the production planning and control system. THE CONFLICT It was obvious that something was wrong when Tony walked into Peter's office. He placed the OWL system brochures on his desk and sat down. He explained to Peter that he had joined Mike at the pub later the previous evening and mentioned Peter's concerns about their ability to cope with the Sellecks order. Mike's response was immediate and hostile. Steve had joined in the conversation to emphasize that they had to cope: there was no choice in this one. Besides, there was no capacity reason why they shouldn't manage. Tony had suggested they at least should buy the additional production planning and control modules to help Peter and Harish with the workload. This seemed to add fuel to the fire. Mike seemed to think they would waste time playing about with computers while they should be making sure the Sellecks order was made on time. His wife Mary had also chipped in at this point and said the computer wasn't for production planning anyway, it had been bought for her to do the ledgers. That had killed the debate. Meanwhile, Harish had been given the first sales order and schedule information on Sellecks and had been doing some calculations on what materials would be required to meet it. The first part, a new design of spade, part number 00289 , had the following requirements: Period 24300 Period 25200 Period 27400 Period 29500 As it was a new design of spade, he got the BOM from Tony Farnham. Tony had already calculated the batch sizes that would enable them to recover the set-up costs on the machines. He had also worked out how long should be allowed for the batches to be made or bought. This information is shown below in. Tables 27.2 and 27.3. As most of the parts were already used in existing designs, Harish did a quick check of the stock situation for each one by looking at the bin cards. This is shown in Table 27.4 . Harish set to work to calculate manually how many of each part were required and when. To help him he drew up a form similar to that used in an MRP system (copy attached in Appendix 27.1). From his calculations, he immediately saw a problem in satisfying the Sellecks order

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started