Question

Munson Manufacturing, in Gainesville, Florida, wants to arrange its four work centers so as to minimize interdepartmental parts handling costs. The flows and existing facility

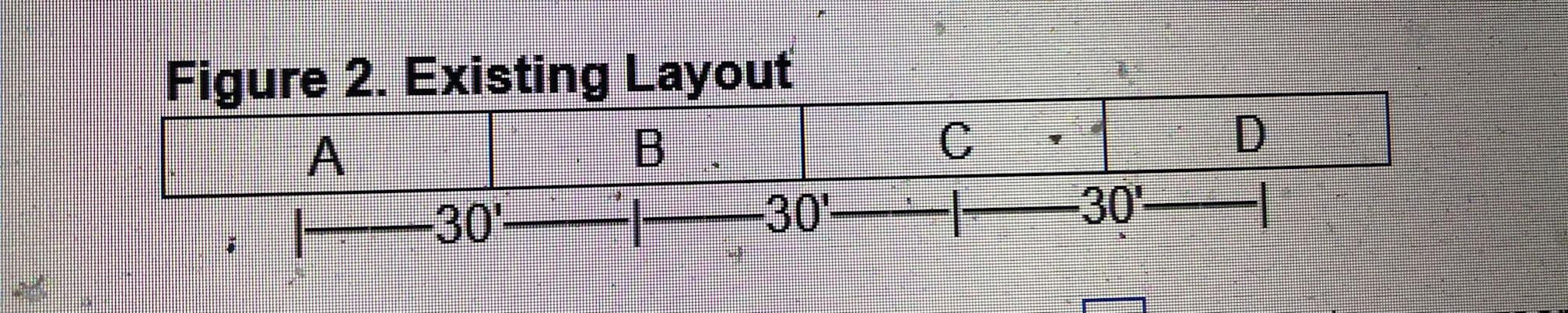

Munson Manufacturing, in Gainesville, Florida, wants to arrange its four work centers so as to minimize interdepartmental parts handling costs. The flows and existing facility layout are shown in the figures below.

| Figure 1. Parts Moved Between Work Centers | ||||||||

| A | B | C | D | |||||

| A | 450 | 600 | 60 | |||||

| B | 325 | 225 | 0 | |||||

| C | 0 | 0 | 700 | |||||

| D | 0 | 0 | 0 | |||||

1)

a. For the existing layout, the cumulative "loaddistance" or "movement cost"= _____ feet (enter your response as a whole number).

b. Based on the flows shown in the matrix, one should expect that the center A and _____ (A, B, C or D) will be next to each other as they have the highest number of moves between each other.

c. Based on the flows shown in the matrix, one should expect that centers C and _____ (A, B, C or D) will be next to each other as they have the second highest number of moves between each other.

2.

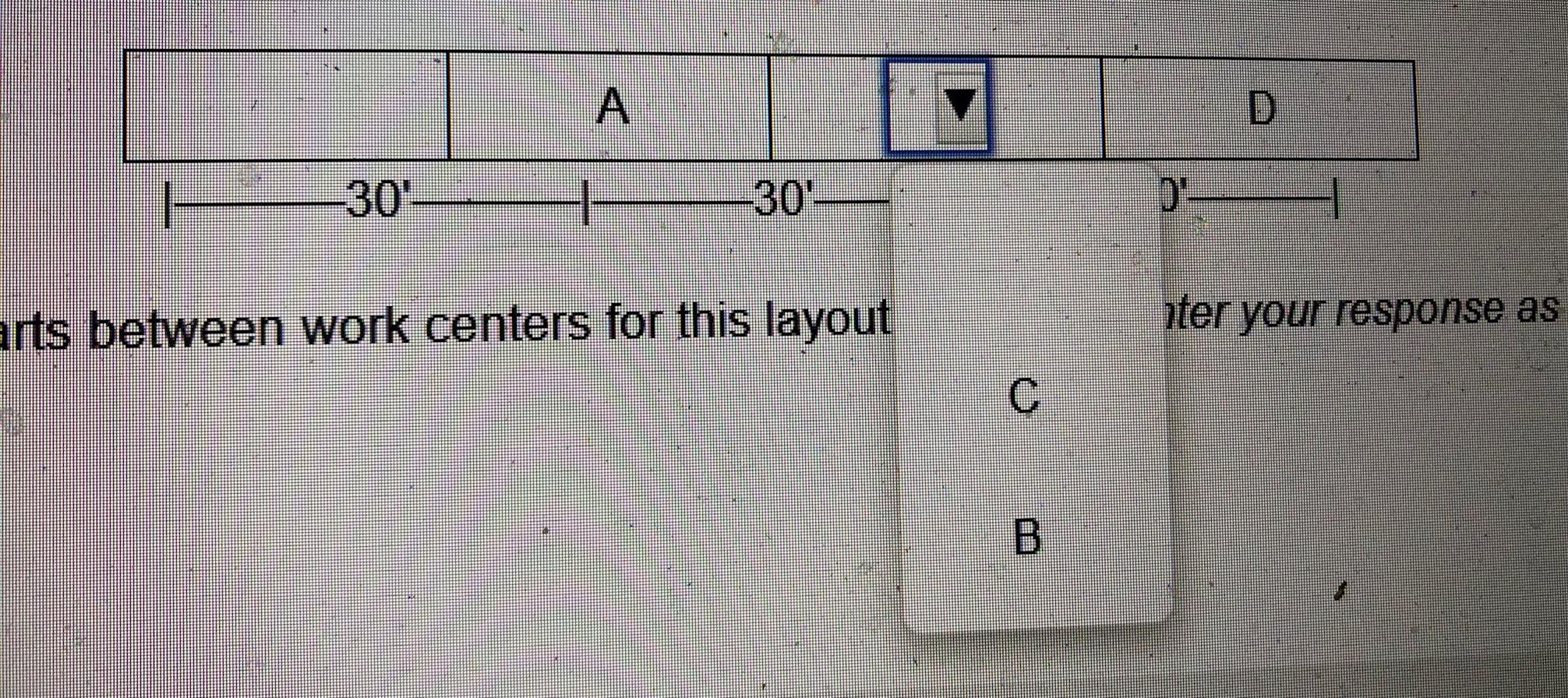

a. The aim is to improve the layout so that the total "movement cost" can be reduced. Functional locations for A and D have been fixed. In the improved layout, the work center that should be located between them is:

C or B

b. The cumulative distance based on the overall movement of parts between work centers for this layout = _______enter your response here feet (round to nearest whole number)

Figure 2. Existing Layout between work centers for this layout ter your response as C BStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started