Answered step by step

Verified Expert Solution

Question

1 Approved Answer

NANA NOODLES Co. is a multinasional company engaged in the Food & Beverage Industry and produces a wide range of instant and dry noodles

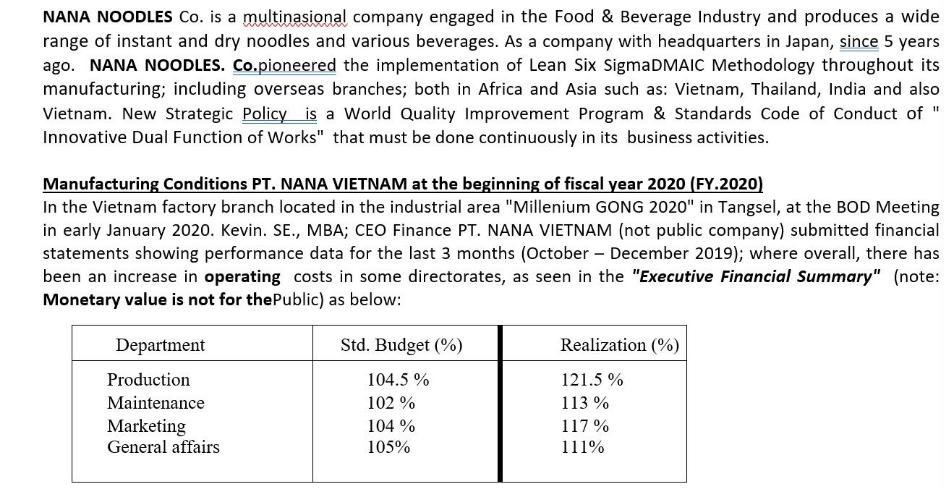

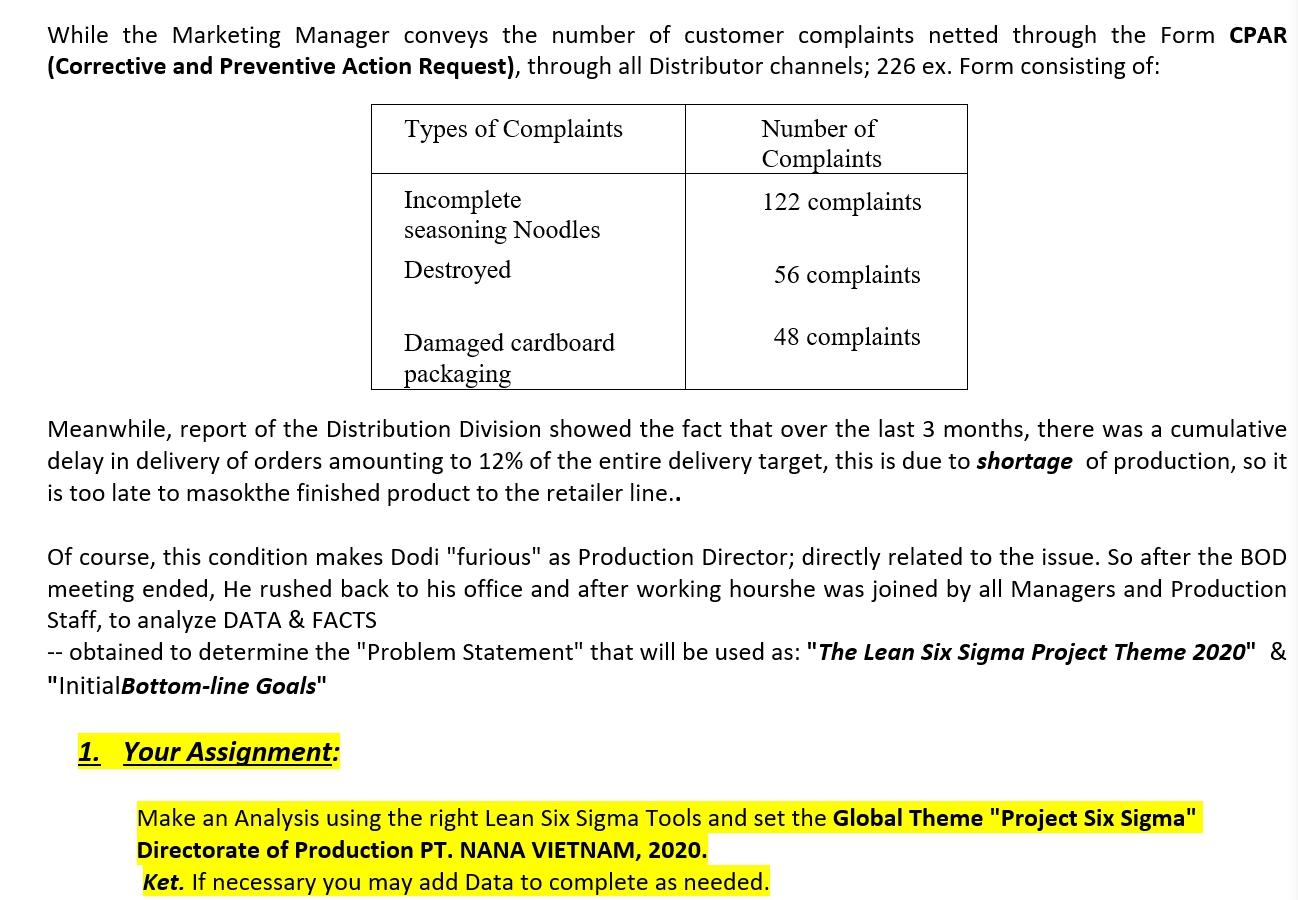

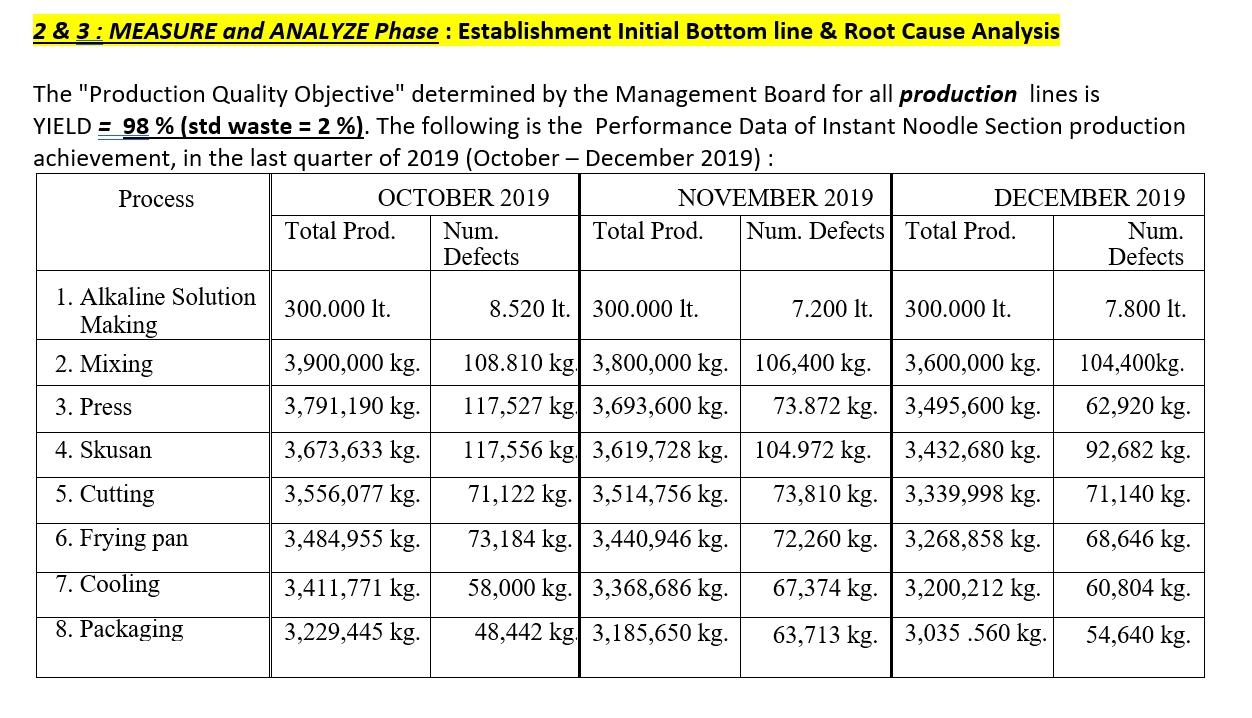

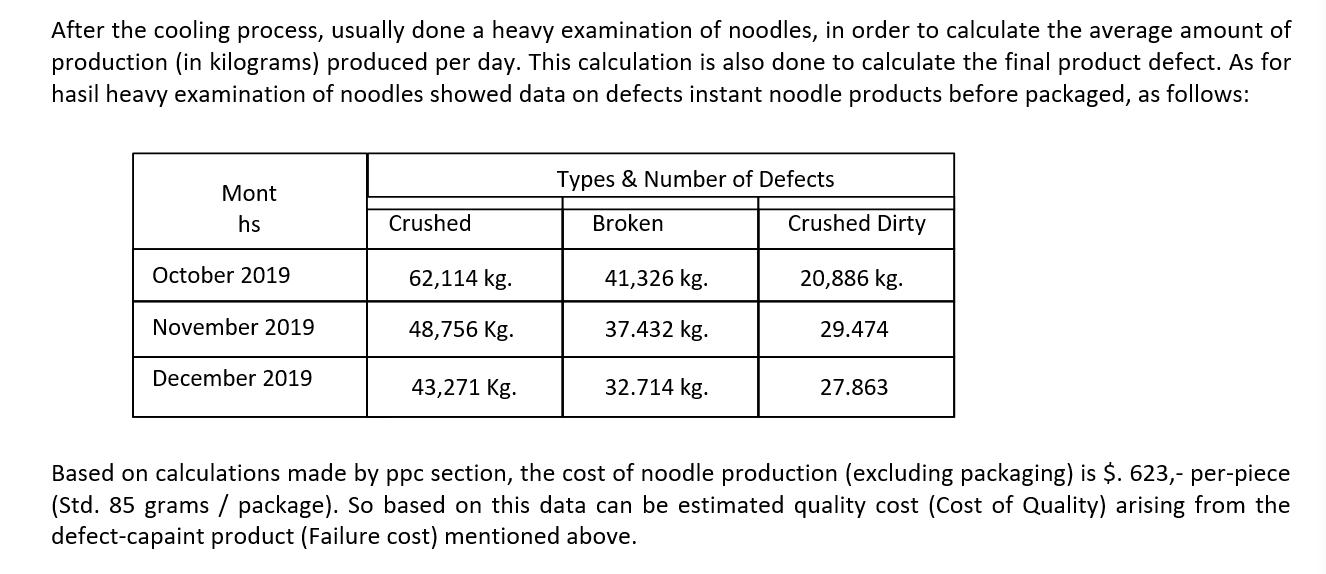

NANA NOODLES Co. is a multinasional company engaged in the Food & Beverage Industry and produces a wide range of instant and dry noodles and various beverages. As a company with headquarters in Japan, since 5 years ago. NANA NOODLES. Co.pioneered the implementation of Lean Six SigmaDMAIC Methodology throughout its manufacturing; including overseas branches; both in Africa and Asia such as: Vietnam, Thailand, India and also Vietnam. New Strategic Policy is a World Quality Improvement Program & Standards Code of Conduct of Innovative Dual Function of Works" that must be done continuously in its business activities. Manufacturing Conditions PT. NANA VIETNAM at the beginning of fiscal year 2020 (FY.2020) In the Vietnam factory branch located in the industrial area "Millenium GONG 2020" in Tangsel, at the BOD Meeting in early January 2020. Kevin. SE., MBA; CEO Finance PT. NANA VIETNAM (not public company) submitted financial statements showing performance data for the last 3 months (October - December 2019); where overall, there has been an increase in operating costs in some directorates, as seen in the "Executive Financial Summary" (note: Monetary value is not for the Public) as below: Department Production Maintenance Marketing General affairs Std. Budget (%) 104.5 % 102 % 104 % 105% Realization (%) 121.5 % 113% 117% 111% While the Marketing Manager conveys the number of customer complaints netted through the Form CPAR (Corrective and Preventive Action Request), through all Distributor channels; 226 ex. Form consisting of: Types of Complaints Incomplete seasoning Noodles Destroyed Damaged cardboard packaging Number of Complaints 122 complaints 56 complaints 48 complaints Meanwhile, report of the Distribution Division showed the fact that over the last 3 months, there was a cumulative delay in delivery of orders amounting to 12% of the entire target, this is due to rtage of product so it is too late to masokthe finished product to the retailer line.. Of course, this condition makes Dodi "furious" as Production Director; directly related to the issue. So after the BOD meeting ended, He rushed back to his office and after working hourshe was joined by all Managers and Production Staff, to analyze DATA & FACTS -- obtained to determine the "Problem Statement" that will be used as: "The Lean Six Sigma Project Theme 2020" & "InitialBottom-line Goals" 1. Your Assignment: Make an Analysis using the right Lean Six Sigma Tools and set the Global Theme "Project Six Sigma" Directorate of Production PT. NANA VIETNAM, 2020. Ket. If necessary you may add Data to complete as needed. 2 & 3: MEASURE and ANALYZE Phase: Establishment Initial Bottom line & Root Cause Analysis The "Production Quality Objective" determined by the Management Board for all production lines is YIELD = 98% (std waste = 2 %). The following is the Performance Data of Instant Noodle Section production achievement, in the last quarter of 2019 (October - December 2019): OCTOBER 2019 Process 1. Alkaline Solution Making 2. Mixing 3. Press 4. Skusan 5. Cutting 6. Frying pan 7. Cooling 8. Packaging Total Prod. 300.000 lt. 3,900,000 kg. 3,791,190 kg. 3,673,633 kg. 3,556,077 kg. 3,484,955 kg. 3,411,771 kg. 3,229,445 kg. Num. Defects NOVEMBER 2019 Total Prod. 8.520 lt. 300.000 lt. 58,000 kg. 48,442 kg 108.810 kg. 3,800,000 kg. 117,527 kg. 3,693,600 kg. 3,619,728 kg. 117,556 kg 71,122 kg. 3,514,756 kg. 73,184 kg. 3,440,946 kg. 3,368,686 kg. 3,185,650 kg. Num. Defects Total Prod. 7.200 lt. 106,400 kg. 73.872 kg. 104.972 kg. 73,810 kg. 72,260 kg. DECEMBER 2019 Num. Defects 67,374 kg. 63,713 kg. 300.000 lt. 3,600,000 kg. 3,495,600 kg. 3,432,680 kg. 3,339,998 kg. 3,268,858 kg. 3,200,212 kg. 3,035.560 kg. 7.800 lt. 104,400kg. 62,920 kg. 92,682 kg. 71,140 kg. 68,646 kg. 60,804 kg. 54,640 kg. After the cooling process, usually done a heavy examination of noodles, in order to calculate the average amount of production (in kilograms) produced per day. This calculation is also done to calculate the final product defect. As for hasil heavy examination of noodles showed data on defects instant noodle products before packaged, as follows: Mont hs October 2019 November 2019 December 2019 Crushed 62,114 kg. 48,756 Kg. 43,271 Kg. Types & Number of Defects Broken 41,326 kg. 37.432 kg. 32.714 kg. Crushed Dirty 20,886 kg. 29.474 27.863 Based on calculations made by ppc section, the cost of noodle production (excluding packaging) is $. 623,- per-piece (Std. 85 grams/ package). So based on this data can be estimated quality cost (Cost of Quality) arising from the defect-capaint product (Failure cost) mentioned above. 4. Your Assignment: 1. First of all, calculate RTY of average production process and give your comments! II. Part two; Do a Six Sigma Quality Analysis, to determine, a.l; A.Six Sigma theme specifically. B. Initial Target (defect ratio dan bottom lines) C. Current Sigma Level and Sigma Level Improvement (Sigma Goals) Advanced Analyze Phase.. After Team Lean Six Sigma Dep. The production was formed, led by a Certified Six Sigma Black Belt, they observed each sub-process of making instant noodles PT. Nana Vietnam today, and the various factors that influence the quality of results in each of these ses, are seen below 1. Alkaline Solution Making Process Factors that affect whether or not quality is homogeneity and alkaline temperature, meaning that if the right temperature (low) is not maintained then the quality of larutan will fluctuate greatly. In addition, the quality factor of raw materials is very influential on the quality of the solution, as well as the consistency and stirring time can also affect the final result of alkaline solution made. 2. Mixing Process Factors that affect the quality of mixing results include, water content in the dough, homogeneity of the dough, the temperature of the dough and the timeliness of mixing the dough. In addition, the condition of the machine can also have a significant effect on result of production in this process. 3. Compressing Process The smoothness of the feeder machine will be the first factor to affect the quality of the press, while the coolnessof the press wheel, the position of the cutting wheel and the cutting bowl also have a significant influence on the production results in thisprocess. Even cleanliness becomes the main determinant of quality. 4. The Process of Reviewing The main factors influencing steaming results are the quality and amount of moisture, in this case the water vapor pressure in the initial bagand the pressure at the end of the process. The condition of the conveyor where the brushing place also affects the quality of noodles. 5. Cutting Process This process is strongly influenced by the tension of the cutting machine drive chain, cutting knife and folding process. 6. Frying Process The process of tidying, soaking in oil, temperature stability and frying time become determinants of the quality of frying results. 7. Cooling Process Things that affect the quality of cooling results are incoming air temperature, fan condition, number of products, noodle wave condition and machine structure. 8. Packaging Process Things that reduce the quality in this process are dis-centering machine with infeed conveyor, to insular tubing conveyor speed, unstable movement infeed conveyor, up&down pressure sealer, temperature sealer, rool height is not uniform, not raw seating time, tension etiquette, miss production code and accuracy that is lacking in inserting seasoning. 5. Your Assignment: Based on the information above, explore the causes of the problem through the technique "5 Why" Root Cause Analysis, described in the "Ishikawa Diagram". Then make conclusions with the tool NGT (Nominal Group Technique) to make Hypothesis about "Dominant Root Causes", before being followed up to the field as proof (Hypothesis Test)

Step by Step Solution

★★★★★

3.44 Rating (160 Votes )

There are 3 Steps involved in it

Step: 1

NANA NOODLES Co is on a mission to improve its production processes using Lean Six Sigma methodologies Lets dive into the analysis and set the Global Theme Project Six Sigma for the Production Directo...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started