Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Novus intends to construct and operate a new oil refinery in Western Australia. Crude oil from Australia, Asia, West Africa, and the Middle East

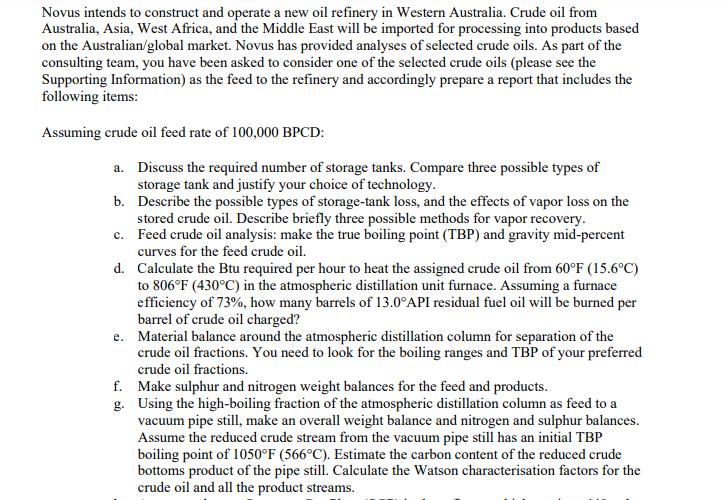

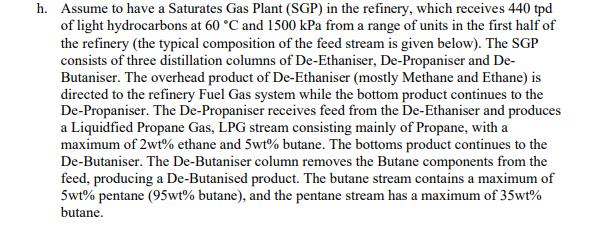

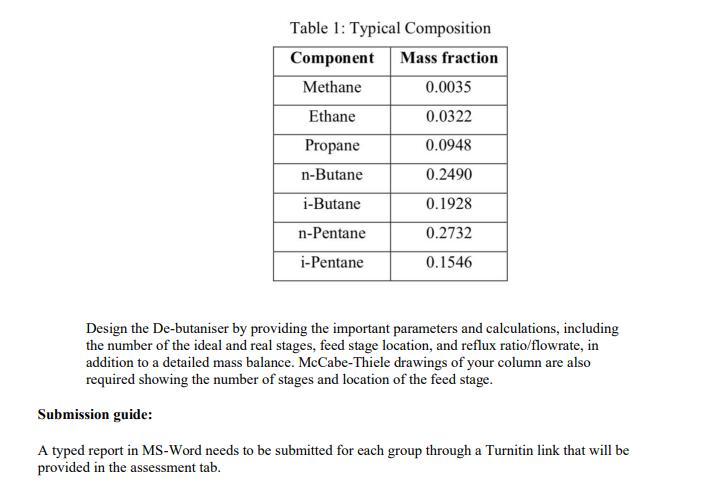

Novus intends to construct and operate a new oil refinery in Western Australia. Crude oil from Australia, Asia, West Africa, and the Middle East will be imported for processing into products based on the Australian/global market. Novus has provided analyses of selected crude oils. As part of the consulting team, you have been asked to consider one of the selected crude oils (please see the Supporting Information) as the feed to the refinery and accordingly prepare a report that includes the following items: Assuming crude oil feed rate of 100,000 BPCD: a. Discuss the required number of storage tanks. Compare three possible types of storage tank and justify your choice of technology. b. Describe the possible types of storage-tank loss, and the effects of vapor loss on the stored crude oil. Describe briefly three possible methods for vapor recovery. Feed crude oil analysis: make the true boiling point (TBP) and gravity mid-percent curves for the feed crude oil. c. d. Calculate the Btu required per hour to heat the assigned crude oil from 60F (15.6C) to 806F (430C) in the atmospheric distillation unit furnace. Assuming a furnace efficiency of 73%, how many barrels of 13.0API residual fuel oil will be burned per barrel of crude oil charged? e. Material balance around the atmospheric distillation column for separation of the crude oil fractions. You need to look for the boiling ranges and TBP of your preferred crude oil fractions. f. g. Make sulphur and nitrogen weight balances for the feed and products. Using the high-boiling fraction of the atmospheric distillation column as feed to a vacuum pipe still, make an overall weight balance and nitrogen and sulphur balances. Assume the reduced crude stream from the vacuum pipe still has an initial TBP boiling point of 1050F (566C). Estimate the carbon content of the reduced crude bottoms product of the pipe still. Calculate the Watson characterisation factors for the crude oil and all the product streams. h. Assume to have a Saturates Gas Plant (SGP) in the refinery, which receives 440 tpd of light hydrocarbons at 60 C and 1500 kPa from a range of units in the first half of the refinery (the typical composition of the feed stream is given below). The SGP consists of three distillation columns of De-Ethaniser, De-Propaniser and De- Butaniser. The overhead product of De-Ethaniser (mostly Methane and Ethane) is directed to the refinery Fuel Gas system while the bottom product continues to the De-Propaniser. The De-Propaniser receives feed from the De-Ethaniser and produces a Liquidfied Propane Gas, LPG stream consisting mainly of Propane, with a maximum of 2wt% ethane and 5wt% butane. The bottoms product continues to the De-Butaniser. The De-Butaniser column removes the Butane components from the feed, producing a De-Butanised product. The butane stream contains a maximum of 5wt% pentane (95wt% butane), and the pentane stream has a maximum of 35wt% butane. Table 1: Typical Composition Component Mass fraction Methane 0.0035 Ethane 0.0322 Propane 0.0948 n-Butane 0.2490 i-Butane 0.1928 n-Pentane 0.2732 i-Pentane 0.1546 Design the De-butaniser by providing the important parameters and calculations, including the number of the ideal and real stages, feed stage location, and reflux ratio/flowrate, in addition to a detailed mass balance. McCabe-Thiele drawings of your column are also required showing the number of stages and location of the feed stage. Submission guide: A typed report in MS-Word needs to be submitted for each group through a Turnitin link that will be provided in the assessment tab.

Step by Step Solution

★★★★★

3.25 Rating (157 Votes )

There are 3 Steps involved in it

Step: 1

Ding Mama teaches at Peking University He has served as Partner Manager for the RSCs Catalysis Science and Innovation program since about 2014 In 2016 ...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started