Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Old Country Links, Incorporated, produces sausages in three production departmentsMixing, Casing and Curing, and Packaging. In the Mixing Department, meats are prepared and ground

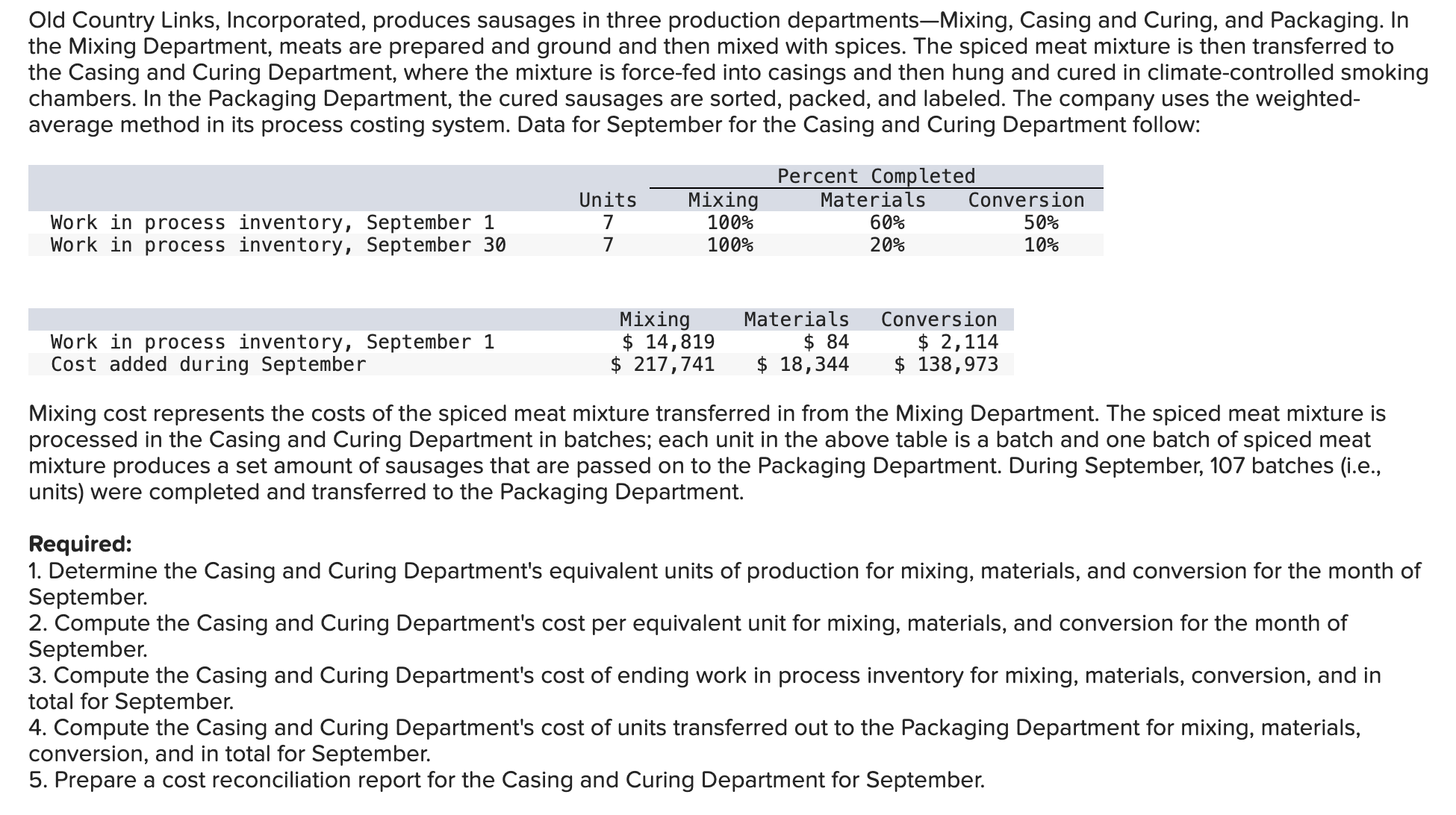

Old Country Links, Incorporated, produces sausages in three production departmentsMixing, Casing and Curing, and Packaging. In the Mixing Department, meats are prepared and ground and then mixed with spices. The spiced meat mixture is then transferred to the Casing and Curing Department, where the mixture is force-fed into casings and then hung and cured in climate-controlled smoking chambers. In the Packaging Department, the cured sausages are sorted, packed, and labeled. The company uses the weighted- average method in its process costing system. Data for September for the Casing and Curing Department follow: Work in process inventory, September 1 Work in process inventory, September 30 Percent Completed Units Mixing 7 100% Materials Conversion 60% 50% 7 100% 20% 10% Work in process inventory, September 1 Cost added during September Mixing $ 14,819 Materials $ 84 $ 217,741 $ 18,344 Conversion $ 2,114 $ 138,973 Mixing cost represents the costs of the spiced meat mixture transferred in from the Mixing Department. The spiced meat mixture is processed in the Casing and Curing Department in batches; each unit in the above table is a batch and one batch of spiced meat mixture produces a set amount of sausages that are passed on to the Packaging Department. During September, 107 batches (i.e., units) were completed and transferred to the Packaging Department. Required: 1. Determine the Casing and Curing Department's equivalent units of production for mixing, materials, and conversion for the month of September. 2. Compute the Casing and Curing Department's cost per equivalent unit for mixing, materials, and conversion for the month of September. 3. Compute the Casing and Curing Department's cost of ending work in process inventory for mixing, materials, conversion, and in total for September. 4. Compute the Casing and Curing Department's cost of units transferred out to the Packaging Department for mixing, materials, conversion, and in total for September. 5. Prepare a cost reconciliation report for the Casing and Curing Department for September.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Given Information Casing and Curing Department data for September Percent completed for Mixing Materials and Conversion Work in process inventory costs for September 1 in Mixing Department Costs added during September for Mixing Materials and Conversion 107 batches completed and transferred to the Packaging Department 1 Equivalent Units of Production EUP for Mixing Materials and Conversion Mixing 100 complete Materials 60 complete Conversion 50 complete Units completed and transferred out 107 batches Equivalent units for Mixing 107 batches 100 107 batches Equivalent units for Materials 107 batches 60 642 batches rounded to 64 batches Equivalent units for Conversion 107 batches 50 535 batches rounded to 54 batches 2 Cost per Equivalent Unit for Mixing Materials and Conversion Cost per EUP for Mixing Cost added for Mixing Equivalent units for Mixing Cost per EUP for Materials Cost added for Materials Equivalent units for Materials Cost per EUP for Conversion Cost added for Conversion Equivalent units for Conversion Cost per EUP for Mixing 217741 107 batches 203531 per batch Cost per EUP for Materials 18344 64 batches 28663 per batch Cost per EUP for Conversion 138973 54 batches 257394 per batch 3 Cost of Ending Work in Process Inventory Cost of ending WIP for Mixing Work in process inventory cost ...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started