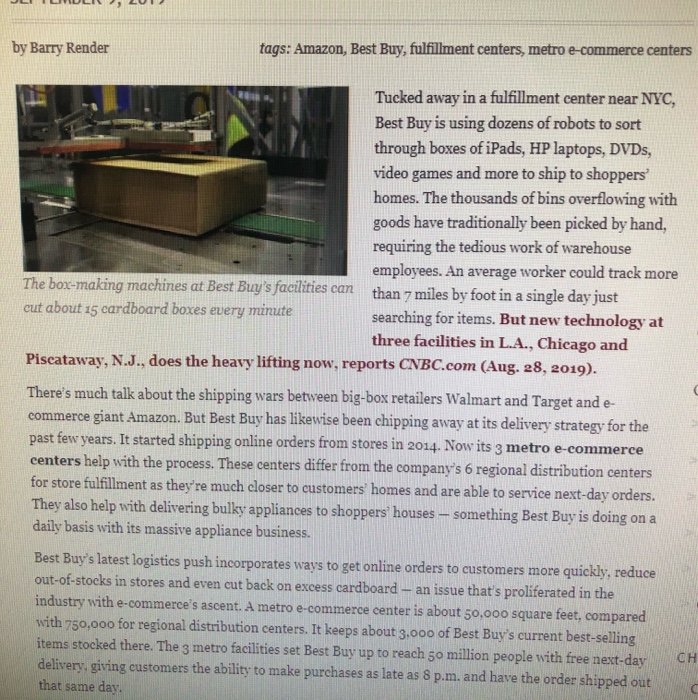

OM in the News: Alexa, Manage My Warehouse MAY 8, 2019 by Barry Render tags: Alexa, Amazon, Echo, voice technology, warehouses As e-commerce order volume continues spiraling upwards while delivery windows shrink, warehouse workers need innovations to meet picking, packing and shipping goals, writes Supply Chain Dive (April 30, 2019). Speech recognition software and voice-directed applications have been used in warehouses since the late 1990s. Even with continued technological advancements, though, adoption is still relatively EL low. About a quarter of warehouses use voice PER directed picking. Traditional voice-directed technologies with headsets and microphones are one solution. New uses of current voice technologies, like Alexa, are another. C Millennial workers are tech-savvy and like incorporating technology in their jobs. They're used to smart speakers with consumer applications like Google Home and Amazon's Echo and Alexa, and the voice systems have similarities. Efficiency is important because individual customers and businesses expect their products to arrive more quickly than in the past. And there's an increased number of small orders. Instead of a business receiving cases of product on a full or mixed pallet once a week, they're getting multiple orders per week with individual products. Those moving to voice-directed technology are often changing from hand-held radio frequency scanning devices. In doing so, they decrease the picking steps in the workflow from 9 steps to around 5 per pick With spoken commands, there's no need to hold a device, which must be put down during the picks. Workers no longer need to look at the device screen and use the keyboard to input or find information. The picks are more accurate because the voice system confirms the picker is at the right location and picked the right items. It increases productivity by 30-45%. JLI ILIIDLIC, 2012 by Barry Render tags: Amazon, Best Buy, fulfillment centers, metro e-commerce centers Tucked away in a fulfillment center near NYC, Best Buy is using dozens of robots to sort through boxes of iPads, HP laptops, DVDs, video games and more to ship to shoppers homes. The thousands of bins overflowing with goods have traditionally been picked by hand, requiring the tedious work of warehouse employees. An average worker could track more The box-making machines at Best Buy's facilities can than 7 miles by foot in a single day just cut about 15 cardboard boxes every minute searching for items. But new technology at three facilities in L.A., Chicago and Piscataway, N.J., does the heavy lifting now, reports CNBC.com (Aug. 28, 2019). There's much talk about the shipping wars between big-box retailers Walmart and Target and e- commerce giant Amazon. But Best Buy has likewise been chipping away at its delivery strategy for the past few years. It started shipping online orders from stores in 2014. Now its 3 metro e-commerce centers help with the process. These centers differ from the company's 6 regional distribution centers for store fulfillment as they're much closer to customers' homes and are able to service next day orders. They also help with delivering bulky appliances to shoppers' houses - something Best Buy is doing on a daily basis with its massive appliance business. Best Buy's latest logistics push incorporates ways to get online orders to customers more quickly, reduce out-of-stocks in stores and even cut back on excess cardboard an issue that's proliferated in the industry with e-commerce's ascent. A metro e-commerce center is about 50,000 square feet, compared with 750,000 for regional distribution centers. It keeps about 3.000 of Best Buy's current best-selling items stocked there. The 3 metro facilities set Best Buy up to reach 50 million people with free next day delivery, giving customers the ability to make purchases as late as 8 p.m. and have the order shipped out that same day. CH Classroom discussion questions: 1. What is the difference between a "metro e-commerce center" and a regional distribution center? 2. How does Best Buy's fulfillment system differ from that of Amazon? 3. What are the advantages of voice systems in warehouse picking