Question

On the night of July 11, 2007, Akshay Mittal, managing director of Chandpur Enterprises Limited (CEL), was staring at a sheet of numbers to decide

On the night of July 11, 2007, Akshay Mittal, managing director of Chandpur Enterprises Limited (CEL), was staring at a sheet of numbers to decide on the raw materials requirement for the August production at his steel plant. He had recently joined his family business after completing his undergraduate degree in engineering. Only two weeks into the job, he had been asked to solve one of the plant’s major problems: the plant manager’s monthly decision to order the optimum quantity of more than half a dozen raw materials required for the following month’s production.

Made before the beginning of every month, it was a critical decision because the prices of raw materials fluctuated continually, and raw materials constituted more than 75% of the total cost of the final product. There was no formal procedure to help decide on the right combination of raw materials, and the plant manager used a rather arbitrary approach to decide the following month’s raw materials consumption. Akshay had spent the last week looking at the last few months’ information, which the plant manager had used to decide the raw materials order. In the past, the monthly profit had been about (Indian rupees) INR1.5 million. It was not difficult to see that one could increase the company’s bottom line by a significant amount each month with a better approach. Akshay was keen to formalize this process once and for all. He had to make his decision for August’s inventory today so he could order the required materials from suppliers the next morning. Otherwise, inventories wouldn’t be on hand well in advance of the beginning of the following month.

Background: CEL was a diversified manufacturing company based in the small town of Chandpur, which was 150 kilometers northeast of Delhi, India. Akshay’s father, Vipin Kumar Mittal, and grandfather, Kailash Chand Mittal, a renowned businessman who was prominent in religious and social endeavors, were responsible for the company. The main business of cinemas, with a strong presence in sugar, was augmented by the manufacturing of paper in 1995. Growing and diversifying, CEL started its steel business in 2006 and its snack foods business in 2007. CEL’s steel division was struggling with the typical hurdles of a start-up. The most important thing was to ensure minimum plant downtime and to maintain costs. And the biggest challenge was to streamline the supply chain and logistics of the fledgling plant.

Ordering Raw Materials

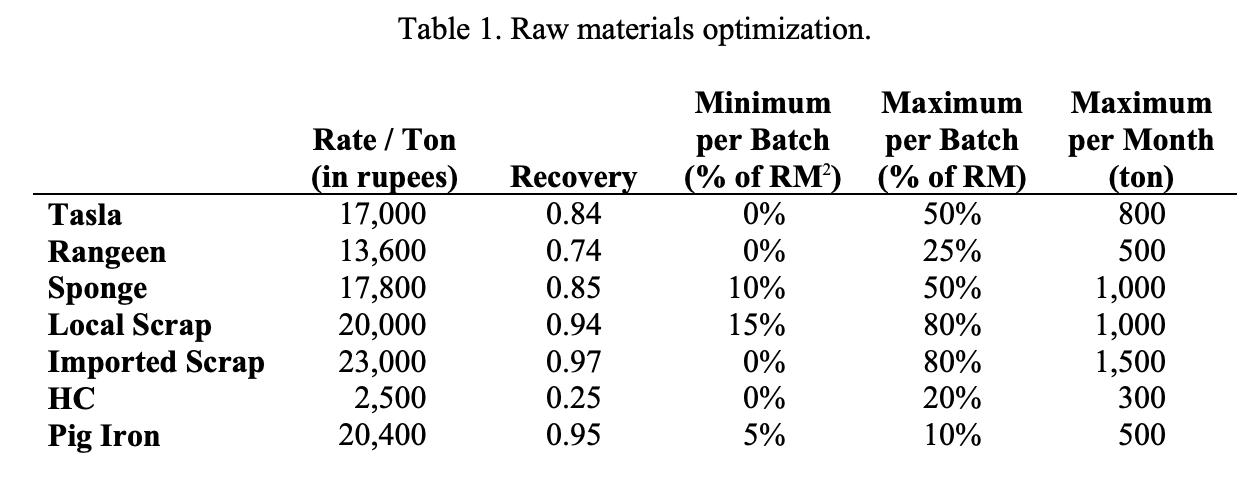

Steel was made in a batch process; it could be produced from a combination of seven raw materials (with different iron content and chemical properties) in proper ratios. The prices of these raw materials could fluctuate up to 20% in a single month’s time, so the choice of the optimal combination of raw materials was even more critical. The lead time for some of these raw materials was up to three weeks, requiring a decision on the following month’s requirement well in advance. The seven types of raw materials were available in different grades, whose prices depended on quality. Grades with higher iron content and superior chemical properties were costlier than lower-grade materials. Akshay had quotes for the seven raw materials, their respective grades and iron content, and chemical properties. To maintain the desired quality of the final product, there were limitations on the maximum and minimum amount of a given material that could be used in a given batch. Pushing these limits risked damaging the furnace where the raw materials were combined and melted or could lead to an inferior product. The limits for individual raw materials are defined as the percentages of total raw material in a batch (Table 1). The size of a batch was required by regulations to be less than 4,000 kilograms of finished product. In the past, it had not been possible to get as much of these raw materials as desired in a given month. The maximum supply quantity was dependent upon many factors, such as capacity of the supplier, season, liquidity in the market, future price expectations, and so on. Along with other information, the suppliers had provided Akshay maximum availability (in tons1 ) for these materials during the following month (August). These monthly limitations would further restrict the use of any raw material combination. Table 1 shows batch limits and monthly limits, purchase price rates, and recovery percentages (ratio of weight of iron content in the finished product to the weight of the raw material) for these seven raw materials:

1. Tasla: a lightweight rusted scrap sourced locally within 500 kilometers. Because of its larger volume per kilogram, long-distance transportation was uneconomical.

2. Rangeen (colored): lightweight scrap of small tin-coated boxes that were painted and had high phosphorus content.

3. Sponge: a processed iron ore sourced directly from processing plants located near iron ore. This was one of the costliest raw materials, but it was needed to maintain the quality of the final product.

4. Local scrap: the result of cutting up discarded machinery, industrial equipment, or construction wreckage. It was of high quality, and its iron content could be up to 95%. 5. Imported scrap: high-quality scrap (e.g., ship cutting) sourced from different parts of the world. Iron content could be up to 97%.

6. HC (high carbon): a carbon-rich material, containing slag (a porous nonmetallic substance), or waste, from big cast-iron plants. Some minimum carbon level was required in the final product. Iron content varied widely.

7. Pig iron: high in carbon. It was used to maintain the carbon content in the final product.

Two prime resources used to produce steel depended on the total weight of the raw materials:

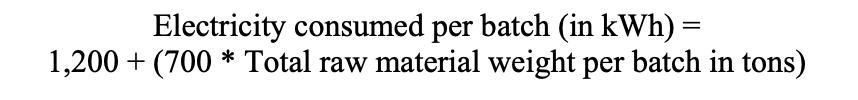

a. Electricity consumption: Electricity usage was proportional to the weight of the raw materials in a batch. More energy would be used (and more wasted) to melt raw materials that had more impurities. Melted impurities were removed from the system in the form of slag. Akshay had run a correlation based on past data and had identified a strong linear relationship (t-stat > 2) between the total weight of raw material per batch and the electricity consumed per batch of finished product within the operating range of raw material tons per batch:

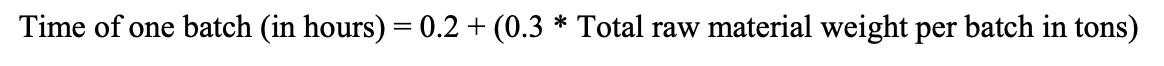

b. Time to produce a batch: More time was needed for a batch that used a higher total amount of raw material. As it was for the electricity resource, more impurities would lead to a longer batch-processing time. Since the plant was run 24 hours a day for 25 working days a month (excluding maintenance time and other shutdowns), the time taken per batch ultimately would decide the final production in a month and final profit per month. Akshay had run a correlation based on past data and had identified a strong relationship (t-stat > 2) between the total amount of raw materials in a batch and the time to produce a batch within the operating range of raw material tons per batch:

Variable costs included salary—approximately INR3,000 per batch—and other expenses in the plant, including consumables, which had been pooled as one expense amounting to roughly INR2,000 per ton of finished goods. The cost of one electricity unit (kWh) was INR4.30.

Akshay had run some technical analysis based on the trend in historical data to determine the price for his final product in the month of August. He was planning to contract out his full production at the price of INR29,000 per ton.

Decision

Akshay didn’t realize he had been thinking about this and playing with the numbers for the last two hours. Suddenly, he heard a knock on the door; his mother was asking him to go to bed soon and to switch off the lights before doing so. He said he would do both and got back to his numbers. What was he going to order tomorrow? Could he formalize this decision-making process? It was going to be hard to get to bed soon.

1) You will formulate a PL model from a realistic situation.2) You will use technological tools to find the optimal solution.

Tasla Rangeen Sponge Local Scrap Imported Scrap HC Pig Iron Table 1. Raw materials optimization. Rate / Ton (in rupees) 17,000 13,600 17,800 20,000 23,000 2,500 20,400 Recovery 0.84 0.74 0.85 0.94 0.97 0.25 0.95 Minimum per Batch (% of RM) 0% 0% 10% 15% 0% 0% 5% Maximum per Batch (% of RM) 50% 25% 50% 80% 80% 20% 10% Maximum per Month (ton) 800 500 1,000 1,000 1,500 300 500

Step by Step Solution

3.52 Rating (152 Votes )

There are 3 Steps involved in it

Step: 1

1 Akshay can formulate a profitmaximizing PL model from his realistic situation He would need to def...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started