Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Oncrations Management Rrolect XYZ Company for. Tea Production comparies. Their fint busiarss in the Midlle East startal in Sadi Anbia in the ( 1930 mathrm{on}

Oncrations Management Rrolect XYZ Company for. Tea Production comparies. Their fint busiarss in the Midlle East startal in Sadi Anbia in the \( 1930 \mathrm{on} \) and by 1978, the fint fasary provess imperevement initiative dat roduces procening time for each bes (the compary epastes In \( 3000, \times Y Z \) esthishod its ies fastory in Dorg El Anab bo produse high quality ira. The lokal 8 hr /day), so that outpot is increased by \( 15 \% 4 \) bet 5 addifienal waken requiral for each Balen for XYZ (the kea fartapy) were afosad 60 Mitlice Epyptian ponds during year 2020 . The prodartion line. Originally, is opcraton are needed to sperate each line (t production lines). campary is eperating under a strakg that aims to provide the best sea latiag experience to itt Openator coats are Li 10hour, and netrrial input is LE Lbos and openting line cost Le 300 fre. cumtomen (differencieion atratrey) Opertorad is charged it 1.4 times direst labor eoat (before and after the propoed initiakive) As a member of the improvemont itam, you are required to amen the fratibilicy of the proposod Fincensting oupur is evenly dactibutod ameng the 7 lines). During the lat board of ditriton meetify, theie was a bot diucwaion abour the firsec of the tes Brodustion nresess and avaliaz the cenutant prewh it sales in years 2018 , 2019 and 2030 . Hewerer, the curreat eonditicns in Ciencrally, frotuction in XYZ coeppany could be consileted at a batels pricesing that peuvides quite high vohume asd equite acseptable vaniety of eutpot. As poeveaaly mentioncel there are 7 prodsctian lines that are used to probuce the 5 difierme byes of products produced by XYZ Lite as wedl (but the 10 pact). Line 6 is uned bo produce the duat while line 7 is uned of prudse the typei of eca postaved are as followe: 1. The warchouse dipueches the gaw ita after reveiving the pouluction order. 2. Afier the raw sea is diypasibed, the certified aca tasers atart wo propove the nocded blend ef tea and thes the blend pecparation itarte. the hewoonseity of the blend. matr guadiny cheris 5. The blent is then moved bs the main uabs acconday ta the tyge of the blend. 6. The blend is than moved to ene of the prodsetion lieses lo be precesset. 7. The final protest is thet nioved to the pekagey itage. Cabacilyla baining

quality ehreks (quality at the acuroe), and to roport any defosts they dincever to their mperviver. content and sensery truting? The olose mataikring of dicp 4 rovealed that the company is froguently facing probkems with the moisture eontent of the tea mikture. The mecegited nons of the mointure contint ranges befween shown in the following table. - Prodact demande per month - Finite rewotirse millahility - Dirinct tevource conta The offoctive in the mathematical mobel is to maximiat ter firmis profi. Therffure, the model pecifie peoductoe yield of that prodect. The resubiag nutiematicel madet is this mernario is a Inventaryand anter folfillarat problem areas. 5 ince the nodel calculates the amount ef differst peodsca in atrance, the tevula The ceenpeny aftempts to minimize the ameeat of ipventury. There in a real need to reatses this can alse be usod foe eenteparinon between oftinal and actual anuensta of probs bish strategy for theif purehases. The carrent model of ordering and imventary ignores ealculation The fellowing table ahows the requiresents of each bok from the mos material, nachise time and econemie order measeses as well as quantify diseounts that might be offered. For comple, the ncedi of XYZ from one of its raw maserials, the raw toas, heing as a crucial ingreficent and importal from an intermational upplier has a total demasd of about 310.000 sonvyed. Ondering costs are \( \$ 24000 \) per order, camying costa are 535 per 100 per yoar, Orden lest than 20,060 ken will coit 518 per ton, 20.000 and lese than \( 30.000 \mathrm{wil} \) coot 517.5 per ton, and lagger orlen will cud 516 per ton. The lead-uime needed froms placiag an onder untit having the order is around I deys on average with standart deviation 2.5 days. while the required service level is \( 95 \% \) Averegate Rannining Plannen af the cogpany we about to prepare the agqrqate plan that will cever 6 momht. Asumieg that ile company idenuficd the following foresast for the mect 6 mondhe They nom want to sualuate a plan that call. fior a seraty nate of repular esefer (24050) They intend to sar with zero imentory an hasd in the finit period. They decided so ue overtime

Assess the two alternatives (outsourcing vs insourcing) and determine the appropriate decision based on 2021 forecast and determine when it is appropriate to outsource and which year the new production line is a must. - Assess the proposed improvement initiative using the actual demand of 2020. - Review and assess the process of inspection undertaken by XYZ. - Review and assess the inventory decisions facing XYZ - Prepare an aggregate plan for the first 6 months of 2021 based on the given forecasted demand. - Prepare a linear programming model that determine the optimal product mix. - In each module of the case provide a theoretical background regarding the topic no more than 2 pages for each module

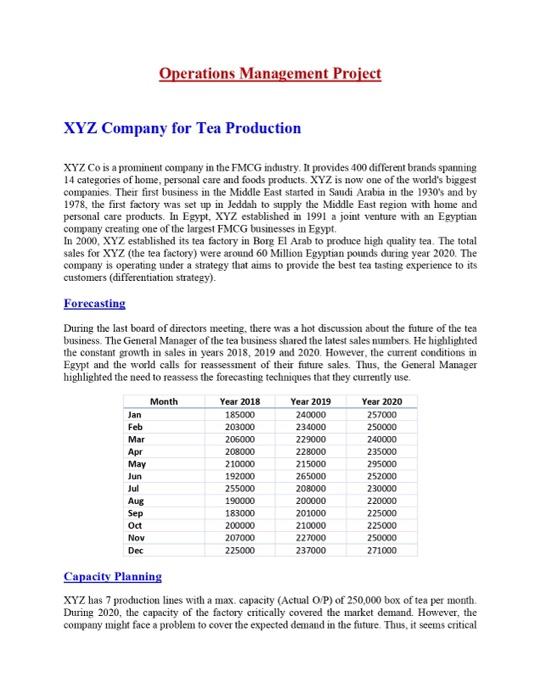

XYZ Co is a prominent company in the FMCG industry. It provides 400 different brands spanning 14 categories of home, personal care and foods products. XYZ is now one of the world's biggest companies. Their first business in the Middle East started in Saudi Arabia in the 1930's and by 1978, the first factory was set up in Jeddah to supply the Middle East region with home and personal care products. In Egypt, XYZ established in 1991 a joint venture with an Egyptian company creating one of the largest FMCG businesses in Egypt. In 2000, XYZ established its tea factory in Borg El Arab to produce high quality tea. The total sales for XYZ (the tea factory) were around 60 Million Egyptian pounds during year 2020. The company is operating under a strategy that aims to provide the best tea tasting experience to its customers (differentiation strategy). Forecasting During the last board of directors meeting, there was a hot discussion about the future of the tea business. The General Manager of the tea business shared the latest sales numbers. He highlighted the constant growth in sales in years 2018, 2019 and 2020. However, the current conditions in Egypt and the world calls for reassessment of their future sales. Thus, the General Manager highlighted the need to reassess the forecasting techniques that they currently use. Capacity Planning XYZ has 7 production lines with a max. capacity (Actual OP) of 250,000 box of tea per month. During 2020, the capacity of the factory critically covered the market demand. However, the company might face a problem to cover the expected demand in the future. Thus, it seems critical

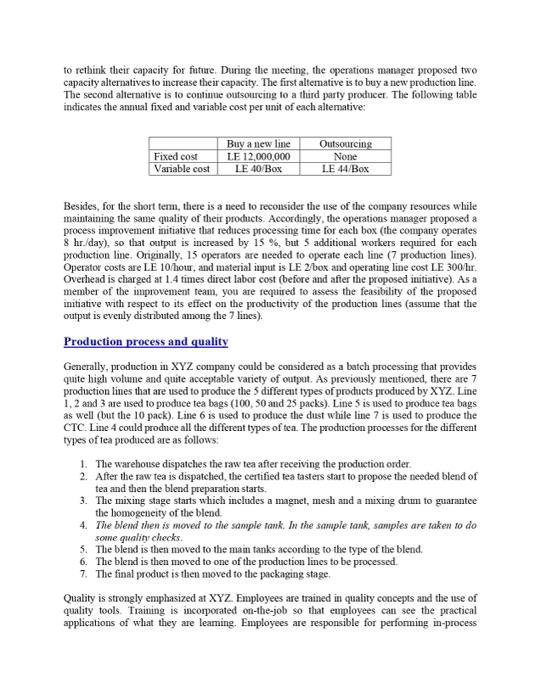

to rethink their capacity for future. During the meeting, the operations manager proposed two capacity alternatives to increase their capacity. The first alternative is to buy a new production line. The second alternative is to continue outsourcing to a third party producer. The following table indicates the annual fixed and variable cost per unit of each alternative: Besides, for the short term, there is a need to reconsider the use of the company resources while maintaining the same quality of their products. Accordingly, the operations manager proposed a process improvement initiative that reduces processing time for each box (the company operates 8 hr day). so that output is increased by \( 15 \% \) but 5 additional workers required for each production line. Originally, 15 operators are needed to operate each line (7 production lines). Operator costs are LE 10/hour, and material input is LE 2 box and operating line cost LE 300 hr. Overhead is charged at 1.4 times direct labor cost (before and after the proposed initiative). As a member of the improvement team, you are required to assess the feasibility of the proposed initiative with respect to its effect on the productivity of the production lines (assume that the output is evenly distributed among the 7 lines). Production process and quality Generally, production in XYZ company could be considered as a batch processing that provides quite high volume and quite acceptable variety of output. As previously mentioned, there are 7 production lines that are used to produce the 5 different types of products produced by XYZ. Line 1,2 and 3 are used to produce tea bags \( (100,50 \) and 25 packs). Line 5 is used to produce tea bags as well (but the 10 pack). Line 6 is used to produce the dust while line 7 is used to produce the CTC. Line 4 could produce all the different types of tea. The production processes for the different types of tea produced are as follows: 1. The warehouse dispatches the raw tea after receiving the production order. 2. After the raw tea is dispatched, the certified tea tasters start to propose the needed blend of tea and then the blend preparation starts. 3. The mixing stage starts which includes a magnet, mesh and a mixing drum to guarantee the homogeneity of the blend. 4. The blend then is moved to the sample tank. In the sample tank samples are taken to do some quality checks. 5. The blend is then moved to the main tanks according to the type of the blend. 6. The blend is then moved to one of the production lines to be processed. 7. The final product is then moved to the packaging stage. Quality is strongly emphasized at XYZ. Employees are trained in quality concepts and the use of quality tools. Training is incorporated on-the-job so that employees can see the practical applications of what they are learning. Employees are responsible for performing in-process

quality checks (quality at the source), and to report any defects they discover to their supervisor. In that sense, several quality checks are performed (step 4); moisture content, bulk density, dust content and sensory testing. The close monitoring of step 4 revealed that the company is frequently facing problems with the moisture content of the tea mixture. The accepted norm of the moisture content ranges between \( 6 \% \) to \( 8 \% \). The standard deviation of the process is \( 0.25 \% \). So, the quality team decided to collect a sample data ( 20 samples each with 5 observations) about the moisture content (in percentage) as shown in the following table: Inventory and order fulfillment The company attempts to minimize the amount of inventory. There is a real need to reassess this strategy for their purchases. The current model of ordering and inventory ignores calculating economic order measures as well as quantity discounts that might be offered. For example, the needs of XYZ from one of its raw materials, the raw tea; being as a crucial ingredient and imported from an international supplier has a total demand of about 310,000 tons year. Ordering costs are \( \$ 24000 \) per order, carrying costs are \( \$ 35 \) per ton per year. Orders less than 20,000 tons will cost \( \$ 18 \) per ton, 20,000 and less than 30,000 will cost \( \$ 17.5 \) per ton, and larger orders will cost \( \$ 16 \) per ton. The lead-time needed from placing an order until having the order is around 8 days on average with standard deviation 2.5 days. While the required service level is \( 95 \% \) Aggregate Planning Planners of the company are about to prepare the aggregate plan that will cover 6 months. Assuming that the company identified the following forecast for the next 6 months: They now want to evaluate a plan that calls for a steady rate of regular output \( (250000 \) boxes (month), mainly using inventory to absorb the uneven demand but allowing some backlog. They intend to start with zero inventory on hand in the first period. They decided to use overtime to make up for lost output. The maximum amount of overtime output per period is 35000 box per month. The regular production cost per box is \( 30 \mathrm{LE} \) while the overtime cost per box is \( 35 \mathrm{LE} \). The holding cost is 5 LE per box per month and the backorder cost is 10 L.E per box per month. Scanned with CamScanner

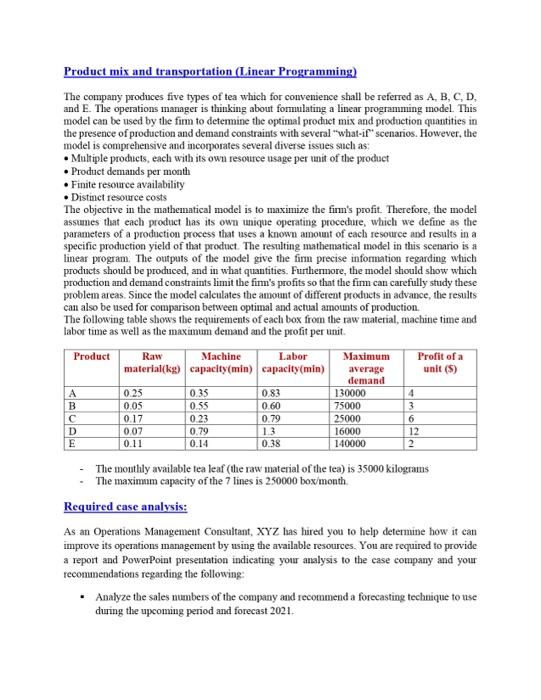

Product mix and transportation (Linear Programming) The company produces five types of tea which for convenience shall be referred as \( , \mathrm{A}, \mathrm{B}, \mathrm{C}, \mathrm{D} \), and \( \mathrm{E} \). The operations manager is thinking about formulating a linear programming model. This model can be used by the firm to determine the optimal product mix and production quantities in the presence of production and demand constraints with several "what-if" seenarios. However, the model is comprehensive and incorporates several diverse issues such as: - Multiple products, each with its own resource usage per unit of the product - Product demands per month - Finite resource availability - Distinct resource costs The objective in the mathematical model is to maximize the firn's profit. Therefore, the model assumes that each product has its own unique operating procedure, which we define as the parameters of a production process that uses a known amount of each resource and results in a specific production yield of that product. The resulting mathematical model in this scenario is a linear program. The outputs of the model give the firm precise information regarding which products should be produced, and in what quantities. Furthermore, the model should show which production and demand constraints limit the firm's profits so that the firm can carefully study these problem areas. Since the model calculates the amount of different products in advance, the results can also be used for comparison between optimal and actual amounts of production. The following table shows the requirements of each box from the raw material, machine time and labor time as well as the maximum demand and the profit per unit. - The monthly available tea leaf (the raw material of the tea) is 35000 kilograms - The maximum capacity of the 7 lines is 250000 box/month. Required case analysis: As an Operations Management Consultant, XYZ has hired you to help determine how it can improve its operations management by using the available resources. You are required to provide a report and PowerPoint presentation indicating your analysis to the case company and your recommendations regarding the following: - Analyze the sales numbers of the company and recommend a forecasting technique to use during the upeoming period and forecast 2021.

- Assess the two alternatives (outsourcing vs insourcing) and determine the appropriate decision based on 2021 forecast and determine when it is appropriate to outsource and which year the new production line is a must. - Assess the proposed improvement initiative using the actual demand of 2020. - Review and assess the process of inspection undertaken by XYZ - Review and assess the inventory decisions facing XYZ - Prepare an aggregate plan for the first 6 months of 2021 based on the given forecasted demand. - Prepare a linear programming model that determine the optimal product mix. - In each module of the case provide a theoretical background regarding the topic no more than 2 pages for each module CS Scanned with CamScanner

XYZ Co is a prominent company in the FMCG industry. It provides 400 different brands spanning 14 categories of home, personal care and foods products. XYZ is now one of the word's biggest compamies. Their first business in the Middle East started in Saudi Arabia in the 1930's and by 1978 , the first factory was set tip in Jeddah to sapply the Middle East region with home and personal care products. In Egypt, XYZ established in 1991 a joint venture with an Egyptian company creating one of the largest FMCG businesses in Egypt. In 2000, XYZ established its tea factory in Borg El Arab to produce high quality tea. The total sales for XYZ (the tea factory) were around 60 Million Egyptian pounds during year 2020. The company is operating under a strategy that aims to provide the best tea tasting experience to its customers (differentiation strategy). Forecasting During the last board of directors meeting, there was a hot discussion about the future of the tea business. The General Manager of the tea business shared the latest sales numbers. He highlighted the constant growth in sales in years 2018, 2019 and 2020 . However, the current conditions in Egypt and the world calls for reassessment of their future sales. Thus, the General Manager highlighted the need to reassess the forecasting techniques that they currently use. Capacity Planning XYZ has 7 production lines with a max. capacity (Actual \( O P \) ) of 250,000 box of tea per month. During 2020 , the capacity of the factory critically covered the market demand. However, the company might face a problem to cover the expected demand in the future. Thus, it seems critical

to rethink their eapacity for future. During tle meeting, the operations manager proposed two capacity alternatives to increase their capacity. The first altemative is to buy a new production line. The second alternative is to continue outsourcing to a third party producer. The following table indicates the annual fixed and variable cost per unit of each altemative: Besides, for the short term, there is a need to recousider the use of the company resources while maintaining the same quality of their products. Accordingly, the operations manager proposed a process improvement initiative that reduces processing time for each box (the company operates 8 hr/day), so that output is increased by \( 15 \% \), but 5 additional workers required for each production line. Originally, 15 operators are needed to operate each line (7 production lines). Operator costs are LE 10/hou, and material input is LE 2 box and operating line cost LE \( 300 \mathrm{hr} \). Overhead is charged at 1.4 times direct labor cost (before and after the proposed initiative). As a member of the improvement team, you are required to assess the feasibility of the proposed initiative with respect to its effect on the productivity of the production lines (assume that the output is evenly distributed among the 7 lines). Production process and quality Generally, prodnction in XYZ company could be considered as a batch processing that provides quite high volume and quite acceptable variety of output. As previously mentioned, there are 7 production lines that are used to produce the 5 different types of products produced by XYZ. Line 1,2 and 3 are used to produce tea bags (100,50 and 25 packs). Line 5 is used to produce tea bags as well (but the 10 pack). Line 6 is used to produce the dust while line 7 is used to produce the CTC. Line 4 could produce all the different types of tea. The production processes for the different types of tea produced are as follows: 1. The warehouse dispatches the raw tea after receiving the production order. 2. After the raw tea is dispatched, the certified tea tasters start to propose the needed blend of tea and then the blend preparation starts. 3. The mixing stage starts which includes a magnet, mesh and a mixing drum to guarantee the bomogeneity of the blend. 4. The blend then is moved to the sample tank. In the sample tank, samples are aaken to do sowne quality checks. 5. The blend is then moved to the main tanks according to the type of the blend. 6. The blend is then moved to one of the production lines to be processed. 7. The final product is then moved to the packaging stage, Quality is strongly emphasized at XYZ. Employees are trained in quality concepts and the use of quality tools. Training is incorporated on-the-job so that employees can see the practical applications of what they are leaming. Employees are responsible for perfonning in-process

quality checks (quality at the source), and to report any defects they discover to their supervisor. In that sense, several quality checks are performed (step 4); moisture content, bulk density, dust content and sensory testing. The close monitoring of step 4 revealed that the company is frequently facing problems with the moisture content of the tea mixture. The accepted norm of the moisture content ranges between \( 6 \% \) to \( 8 \% \). The standard deviation of the process is \( 0.25 \% \)., So, the quality team decided to collect a sample data (20 samples each with 5 observations) about the moisture content (in percentage) as slown in the following table: Inventory and order fulfiliment The company attempts to minimize the amount of inventory. There is a real need to reassess this strategy for their purchases. The cumrent model of ordering and inventory ignores calculating economic order measares as well as quantity discounts that might be offered. For example, the needs of XYZ from one of its raw materials, the raw tea; being as a crucial ingredient and imported from an intemational supplier has a total demand of abont 310,000 tonsyear. Ordering costs are \( \$ 24000 \) per order, carrying costs are \( \$ 35 \) per ton per year. Orders less than 20,000 tons will cost \( \$ 18 \) per ton, 20,000 and less than 30,000 will cost \( \$ 17.5 \) per ton, and larger orders will cost \( \$ 16 \) per ton. The lead-time needed from placing an order until having the order is around 8 days on average with standard deviation 2.5 days. while the required service level is \( 95 \% \) Aggregate Planning Planners of the company are about to prepare the aggregate plan that will cover 6 months. Assuning that the company identified the following forecast for the next 6 months: They now want to evaluate a plan that calls for a steady rate of regular output (250000 boxes/month), mainly using inventory to absorb the uneven demand but allowing some backlog. They intend to start with zero irventory on hand in the first period. They decided to use overtime to make up for lost output. The maximtun amount of overtime output per period is 35000 box per month. The regular production cost per box is 30 LE while the overtime cost per box is 35 L. . The holding cost is 5 LE per box per month and the backorder cost is 10 LE per box per month.

Product mix and transportation (Linear Programming) The company produces five types of tea which for convenience shall be referred as A, B, C, D, and \( \mathrm{E} \). The operations manager is thinking about formulating a linear programming model. This model can be used by the firm to detemine the optimal product mix and production quantities in the presence of production and demand constraints with several "what-if" scenarios. However, the model is comprehensive and incorporates several diverse issues such as: - Multiple products, each with its own resource usage per unit of the product - Product demands per month - Finite resource availability - Distinct resource costs The objective in the mathematical model is to maximize the firm's profit. Therefore, the model assumes that each product has its own unique operating procedure, which we define as the parameters of a production process that uses a known amount of each resource and results in a specific production yield of that product. The resulting mathematical model in this scenario is a linear program. The outputs of the model give the firm precise information regarding which products should be produced, and in what quantities. Furthermore, the model should show which production and demand constraints limit the firm's profits so that the firm can carefully study these problem areas. Since the model calculates the amount of different products in advance, the results can also be used for comparison between optimal and actual amounts of production. The following table shows the requirements of each box from the raw material, machine time and labor time as well as the maximum demand and the profit per unit. - The mouthly available tea leaf (the raw material of the tea) is 35000 kilograms - The maximum capacity of the 7 lines is 250000 box/month. Required case analysis: As an Operations Management Consultant, XYZ has hired you to help determine how it can improve its operations management by using the available resources. Yous are required to provide a report and Powerpoint presentation indicating your analysis to the case coumany and your recommendations regarding the following: - Analyze the sales numbers of the company and recommend a forecasting technique to use during the upcoming period and forecast 2021.

- Assess the two alternatives (outsourcing vs insourcing) and detemine the appropriate decision based on 2021 forecast and detemine when it is appropriate to outsource and which year the new production line is a must. - Assess the proposed improvement initiative tsing the actual demand of 2020. - Review and assess the process of inspection undertaken by XYZ - Review and assess the inventory decisions facing \( \mathrm{XYZ} \) - Prepare an aggregate plan for the first 6 months of 2021 based on the given forecasted demand. - Prepare a linear pogramuning model that determine the optimal product mix. - In each module of the case provide a theoretical background regarding the topic no more than 2 pages for each module

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started