Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Paige Sloane is the CEO of Paige Sloanes Manufacturing, a company that makes various components for its wireless technology division. In all, the company makes

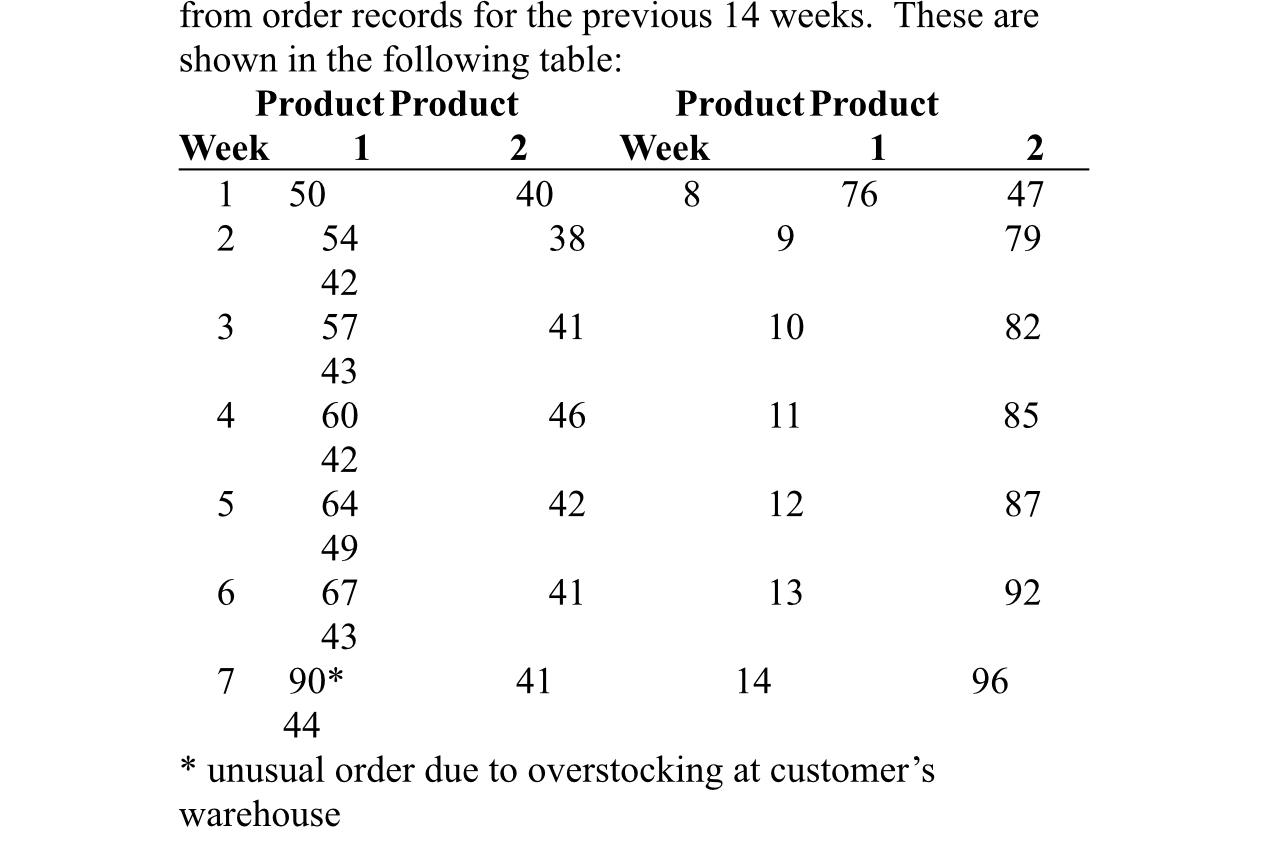

Paige Sloane is the CEO of Paige Sloanes Manufacturing, a company that makes various components for its wireless technology division. In all, the company makes about different items. The two markets the major manufacturer and replacement market require somewhat different handling. For example, replacement products must be packaged individually whereas products are shipped in bulk to the major manufacturer.The company does not use forecasts for production planning. Instead, the operations manager decides which items to produce, and the batch size, based partly on orders, and the amounts in inventory. The products that have the fewest amounts in inventory get the highest priority. Demand is uneven, and the company has experienced being overstocked on some items and out of stock on others. Being understocked has occasionally created tensions with the manger of retail outlets. Another problem is that prices of raw materials have been creeping up although the operations manager thinks that this might be a temporary condition.Because of competitive pressures and falling profits, Paige has asked the Operations Manager to undertake several changes. One change is to introduce more formal forecasting procedures to improve production planning and inventory management. With that in mind, the manager wants to begin forecasting for two products. These products are important for several reasons. First, they account for a disproportionately large share of the companys profits. Second, the manager believes that one of these products will become increasingly important to future growth plans; and third, the other product has experienced periodic outofstock instances. The manager has compiled data on product demand for the two products from order records for the previous weeks. These are shown in the following table:ProductProductProductProductWeek Week unusual order due to overstocking at customers warehouse

Questions: What are some of the potential benefits of a more formalized approach to forecasting? List at least benefits.

You are given the actual values for weeks through for Product and Product Your job now is to prepare a weekly forecast for weeks through for each of Product and Product Start with product and plot the data for the first weeks and show me the graph. Once you decide the technique you feel most closely matches the behavior you have observed in weeks to for Product then plot the data for the full weeks in another graph and show me that graph. Now, look at your plotted data. Do the forecasted weeks make sense visually from what you observed in the first weeks? If not, you likely did not choose the correct technique. That means you have to try another technique. One real world hint the formulas are very useful to help guide you with forecasting but as a manager you have the authority to adjust the forecasted numbers if you think it makes sense to do so In other words, if after applying all of the techniques that you have at your disposal from the chapter you dont see a continuation of the behavior from weeks in any of the forecasted weeks should you adjust any of the weeks Why? Then repeat the above process for Product I need to see all of your work, not just the final numbers please.

from order records for the previous weeks. These are shown in the following table:

Product Product Product Product

tableWeekWeek,

unusual order due to overstocking at customer's warehouse

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started