Answered step by step

Verified Expert Solution

Question

1 Approved Answer

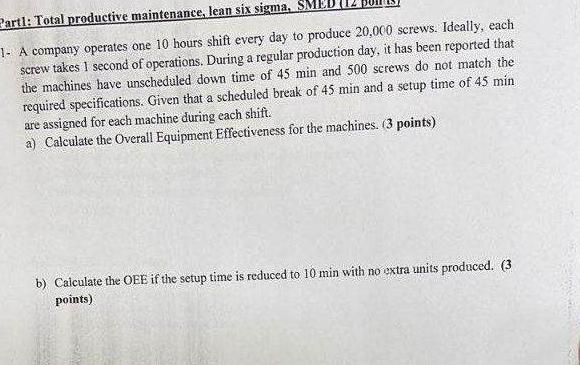

Part 1 : Total productive maintenance, lean six sigma, SMED ( 1 2 poists 1 - A company operates one 1 0 hours shift every

Part: Total productive maintenance, lean six sigma, SMED poists

A company operates one hours shift every day to produce screws. Ideally, each screw takes second of operations. During a regular production day, it has been reported that the machines have unscheduled down time of min and screws do not match the required specifications. Given that a scheduled break of min and a setup time of min are assigned for each machine during each shift.

a Calculate the Overall Equipment Effectiveness for the machines. points

b Calculate the OEE if the setup time is reduced to min with no extra units produced. points

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started