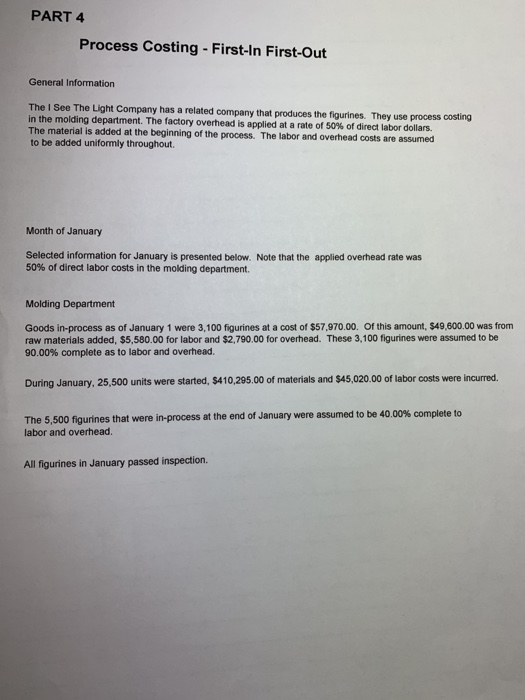

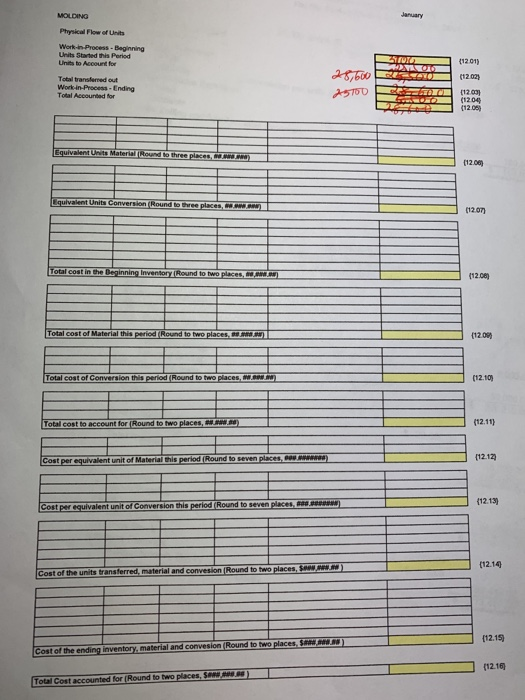

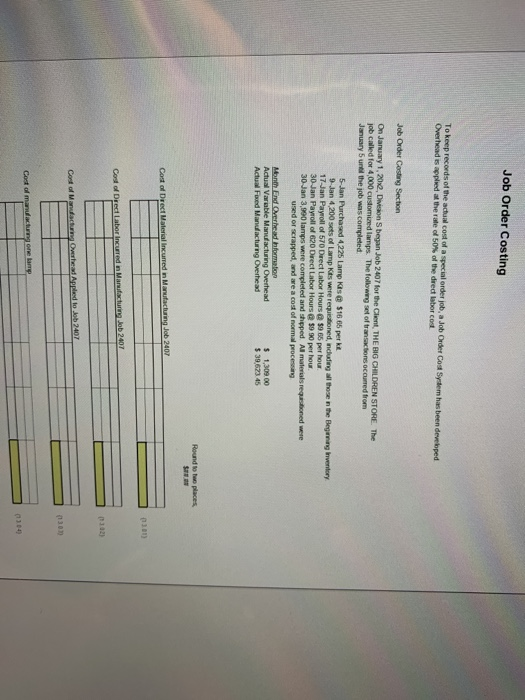

PART 4 Process Costing - First-In First-Out General Information The I See The Light Company has a related company that produces the figurines. They use process costing in the molding department. The factory overhead is applied at a rate of 50% of direct labor dollars. The material is added at the beginning of the process. The labor and overhead costs are assumed to be added uniformly throughout. Month of January Selected information for January is presented below. Note that the applied overhead rate was 50% of direct labor costs in the molding department. Molding Department Goods in-process as of January 1 were 3,100 figurines at a cost of $57.970.00. Of this amount, $49,600.00 was from raw materials added, $5,580.00 for labor and $2,790.00 for overhead. These 3,100 figurines were assumed to be 90.00% complete as to labor and overhead. During January, 25,500 units were started, $410,295.00 of materials and $45,020.00 of labor costs were incurred. The 5,500 figurines that were in-process at the end of January were assumed to be 40.00% complete to labor and overhead All figurines in January passed inspection January MOLDING Physical flow of Units Work in Process - Beginning Units Started this Period Units to Account for H OTO (1201) (1202) 25,600 Total transferred out Work in Process - Ending Total Accounted for 112.00 (1204 112.06 Equivalent Unit Material Round to three places, we TE (12.06) Equivalent Units Conversion Round to three places, (12.07 Total cost in the beginning inventory Round to two places, (12.00 Total cost of Material this period (Round to two places, s 112.00 Total cost of Conversion this period (Round to two places, . + Total cost to account for Round to two places, (12.11) Cost per equivalent unit of Material this period (Round to seven places, www.PHARETA) (12.12) Cost per equivalent unit of Conversion this period (Round to seven places, {12.13) (12.14 Cost of the units transferred, material and convesion (Round to two places, Cost of the ending inventory, material and convesion (Round to two places, T (12.16) Total Cost accounted for [Round to two places, Smas,pa. Job Order Costing To keep records of the actual cost of a special order job, a Job Order Cos System has been developed Overhead is applied at the rate of 60% of the dred labor cost Job Order Casting Section On January 1, 2012, Divan S began Job 2407 for the Client, THE BIG CHILDREN STORE. The job called for 4,000 customized lamps. The following set of transactions occurred from January 5unt the job was completed 5-Jan Purchased 4 225 Lamp Kis@ $16.66 per kt. 9-Jan 4,200 sets of Lamp Kts were requestioned, including those in the Begung ventory 17 Jan Payroll of 570 Drect Labor Hours @ $906 per hour 30 Jan Payroll of 620 Drect Labor Hours $9.90 per hour 30 Jan 3,000 lamps were completed and shipped Al materials requestioned were used or scrapped, and are a cost of normal processing Mont End Overhead formato Actual Varable Manufacturing Overhead Actual Fund Mandacturing Overhead $ 1,309.00 $ 39,623.45 Round to places Material in urred in Manufacturing Job 2407 0301 Cost of Direct labor incurred in Manufacturing Job 2407 Cool of Manufactu r ed Appled to Job 2407 Cort of manufacturing one lamp