Question

Please assist me in discovering, understanding, and answering the problems presented in this assignment: Background: Odis Mullenax is the owner and president of Mullenax Automobile

Please assist me in discovering, understanding, and answering the problems presented in this assignment:

Background:

Odis Mullenax is the owner and president of Mullenax Automobile Parts Inc. His company makes various parts for major automobile manufacturers worldwide. They manufacture intake manifold systems, air induction systems, coolant pump modules, oil filtration systems, coil springs, stabilizer bars, precision springs, and other key components within their three business units. Mullenax is one link in a very long supply chain. Odis understands that the supply chain is not a single line of suppliers and purchasers. Odis knows that the supply chain is more like a complex web where inputs come from multiple directions, often appearing unrelated to one another.

Estella Epperson, vice president of operations at Mullenax, has had her team reviewing the company's demand forecasting system. Estella realizes that demand forecasting is not the only area the company must review to ensure the most efficient and effective operations. Estella discusses Mullenax Automobile Parts' resource planning systems with Joel Kirkwood, director of operations. Resource planning is critical to ascertaining the production capacity required to meet demand. Therefore, it follows Estella's recent initiative concerning demand forecasting.

The challenge in terms of resource planning systems is that Mullenax has three business units. Each unit has different customer requirements and expectations. Although Mullenax works to maximize synergies between the three business units, there are still certain processes that work better in one business unit that the other business units.

Although all the products they produce are important to their customers, some are more important than others. For example, the filtration devices they manufacture are one of the parts of an automobile that requires routine replacement. Filtration devices such as oil, gasoline, diesel, and air filters are part of a vehicle's routine maintenance. However, products related to suspension systems such as springs, coils, and stabilizer bars generally last the life of the vehicle, depending on their use. Therefore, the amount of production capacity is significantly different depending on the product.

The business unit manufacturing diverse filtration devices must guarantee that their products are available in the marketplace all the time. Not only are they required during the initial manufacture of a vehicle, but there must also be a sufficient supply to meet the varying demand that results from different maintenance schedules. The frequency of vehicle usage, the environment the vehicle is used in, and the stress put on the vehicle will dictate how often filtration devices must be replaced. Thus, the demand needs to be considered level or constant over the short-term.

While one may think the same could apply to suspension systems, that is, frequency, environment, and stress could dictate a significant variation, studies have shown that this is not true. These products are more robustly designed than filtering devices and can take a beating. Therefore, the production strategy needed for these products is different than the one needed for the filtering devices. In this situation, the products are more suited for make-to-order since the need is less frequent, and the demand is much lower.

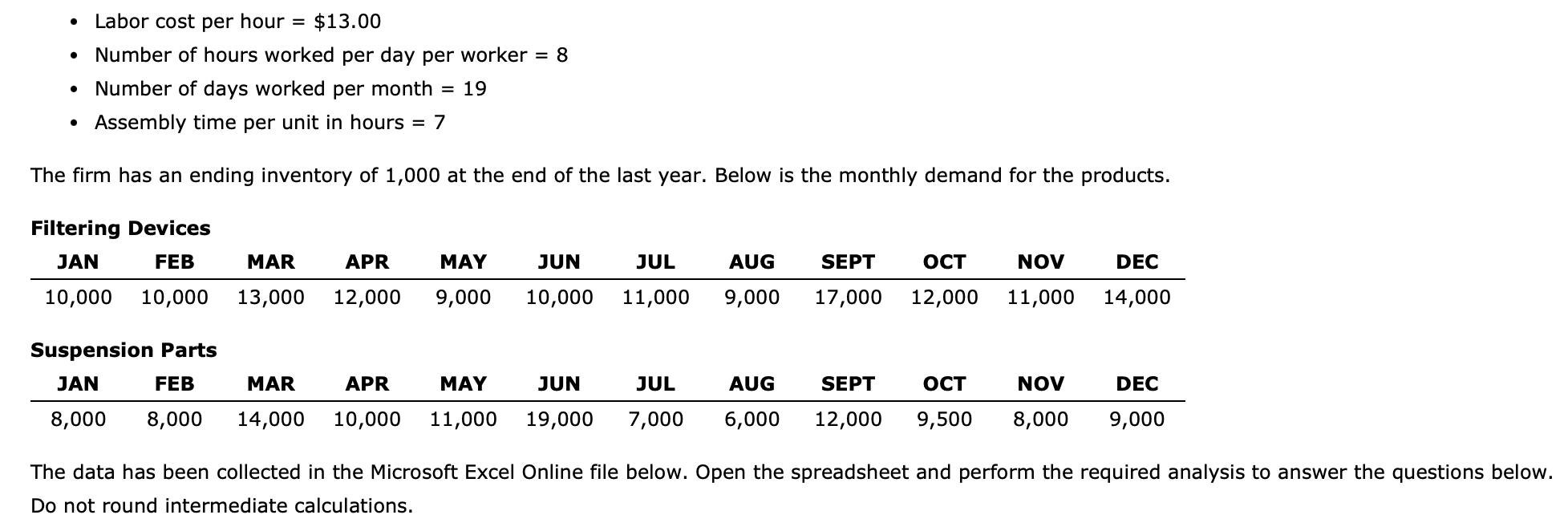

A factor that Joel Kirkwood must consider is his workforce. Labor is a large expense and is tied to the resource planning system utilized. Therefore, Joel needs to select a production method that will ensure capacity meets the specific business unit demand and its labor requirement. Joel is scheduled to meet with Estella on Monday to share his findings. The following are the details for labor cost per hour, number of hours worked per day per worker, number of days worked per month, and assembly time per unit in hours:

- Labor cost per hour = $13.00

- Number of hours worked per day per worker = 8

- Number of days worked per month = 19

- Assembly time per unit in hours = 7

The firm has an ending inventory of 1,000 at the end of the last year. Below is the monthly demand for the products

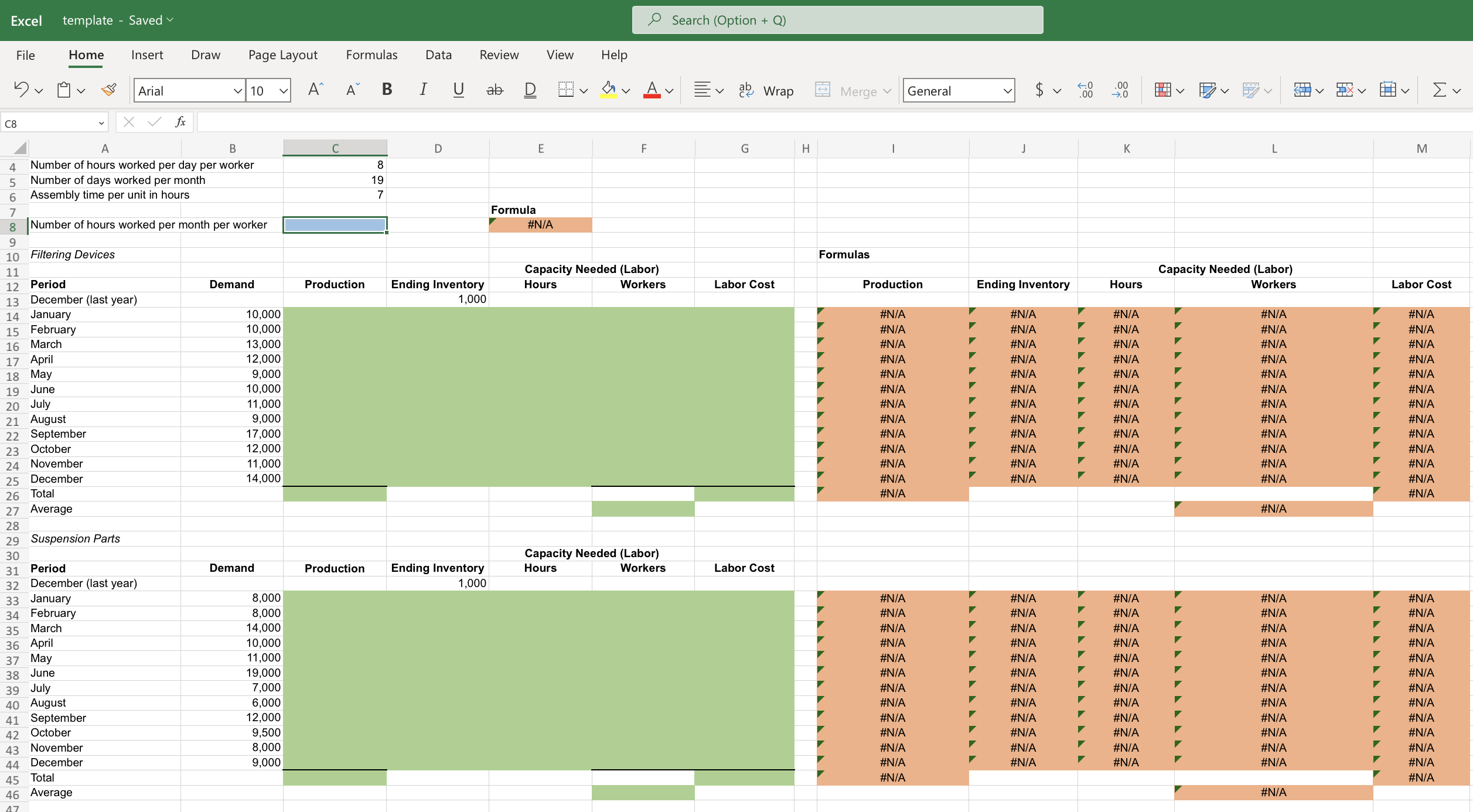

The data has been collected in the Microsoft Excel Online file below. Open the spreadsheet and perform the required analysis to answer the questions below. Do not round intermediate calculations.

Additional Background Info (Excel Spreadsheet):

Question:

1. Based on the information provided in the case, which production strategy would be best for the filtering devices? Why? What is the distinguishing element?

For the filtering devices, the output for production must be ____

constant variable; therefore, the _____ chase-level production strategy is best.

2. Based on the information provided in the case, which production strategy would be best for the suspension parts? Why? What is the distinguishing element?

Since the suspension parts will be required _______(less or more) frequently and their potential price is much ____ (higher or lower) than filtering devices, the _____(chase or level) production strategy is best.

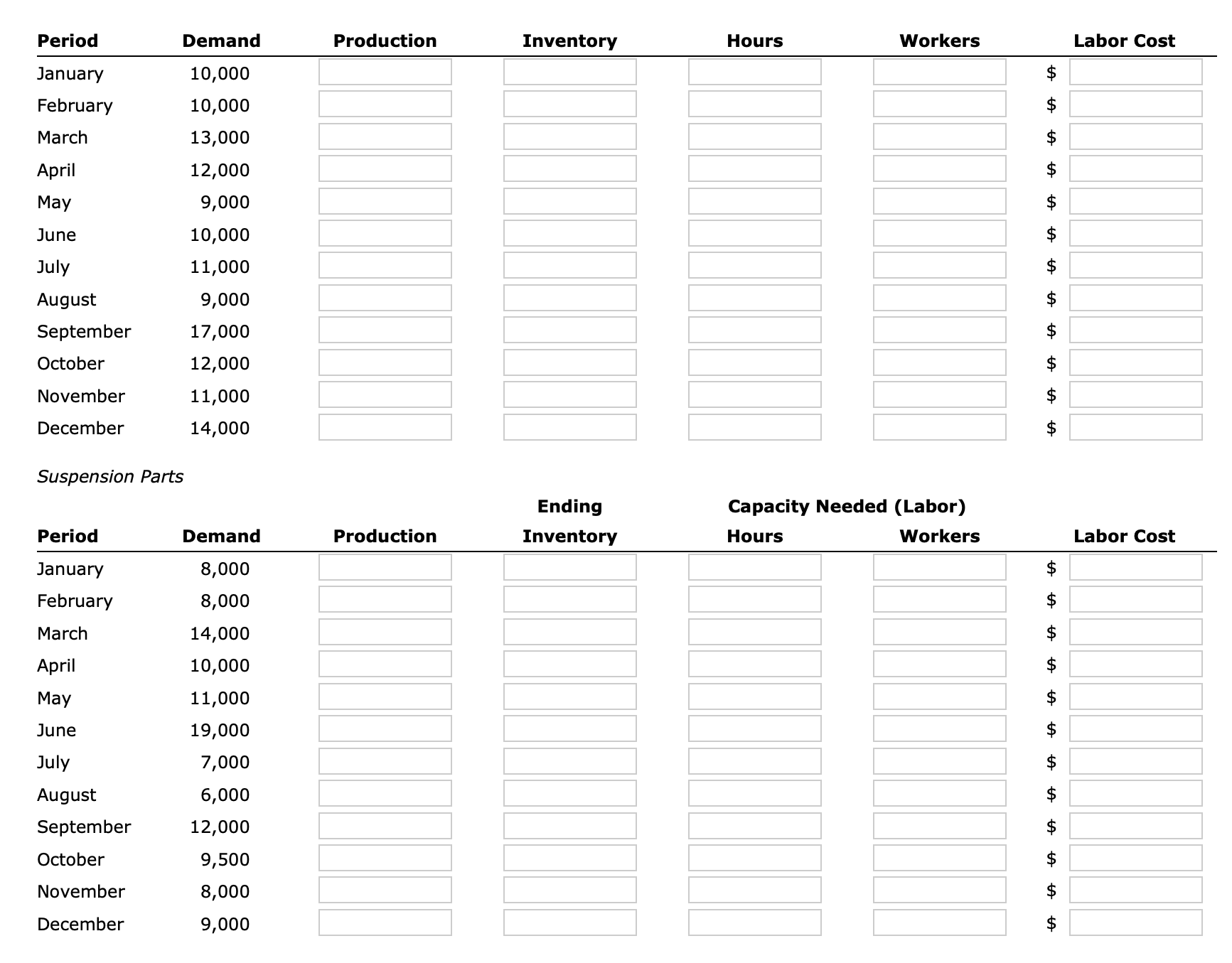

3. Using the information provided on labor cost per hour, number of hours worked per day per worker, number of days worked per month, and assembly time per unit in hours, use the student worksheet and determine the numbers for both the level and chase production strategies. Round your answers for production quantities, ending inventory, and hours needed to the nearest whole number. Round your answers for workers needed up to the nearest whole number. Round your answers for labor cost to the nearest dollar.

Filtering Devices

Assistance Needed:

Please give me the values for every part of the question and all questions.

Note: Thank you for any assistance in answering and understanding this problem.

Suspension Parts - Labor cost per hour =$13.00 - Number of hours worked per day per worker =8 - Number of days worked per month =19 - Assembly time per unit in hours =7 The firm has an ending inventory of 1,000 at the end of the last year. Below is the monthly demand for the products. Filterina Devices Sucnencinn Partc The data has been collected in the Microsoft Excel Online file below. Open the spreadsheet and perform the required analysis to answer the questions belon Do not round intermediate calculations. a. What is the annual demand for the filtering devices? Round your answer to the nearest whole number. b. What is the total annual labor cost for the filtering device workforce? Round your answer to the nearest dollar. $ c. What is the average number of employees per month for the filtering device business unit? Round your answer up to the nearest whole number employees d. What is the annual demand for the suspension parts? Round your answer to the nearest whole number. e. What is the total annual labor cost for the suspension parts workforce? Round your answer to the nearest dollar. $ f. What is the average number of employees per month for the suspension business unit? Round your answer up to the nearest whole number. employeesStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started