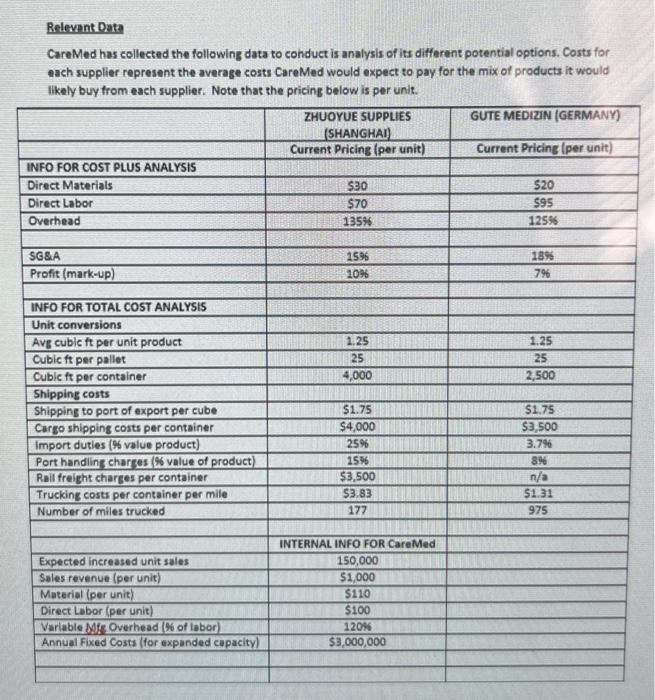

Please complete Question 8

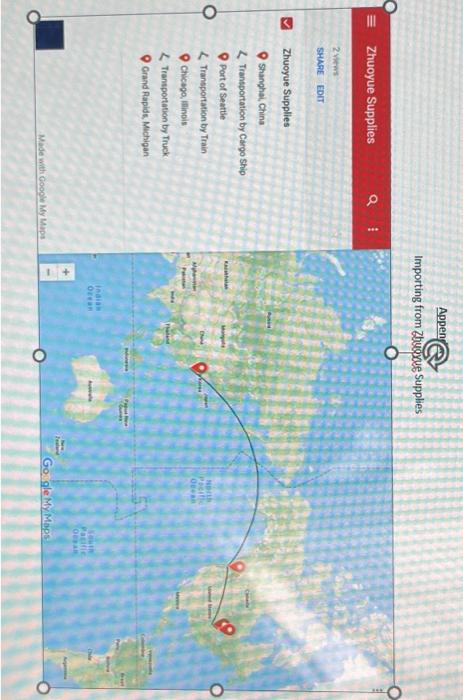

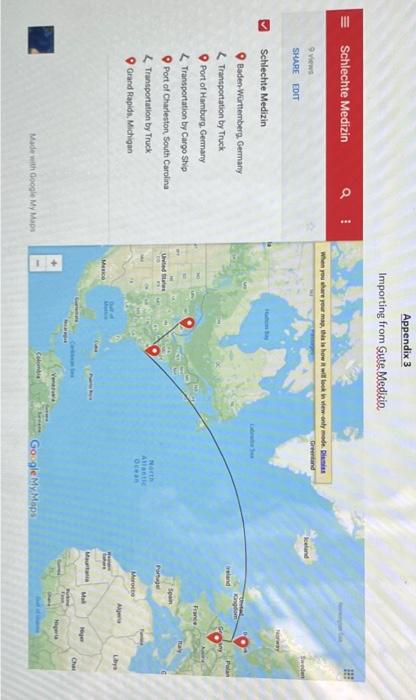

CareMed: Importing Medical Supplies ahead of a Pandemic- The Year 2023 CareMed Inc. sells a wide range of personal protective gear, medical devices, and other medical supplies used in hospitals and private practices [see Appendix 1]. CareMed was founded ten years ago by Morgan Melendez and Victoria Contreras, two nurses who met while completing their MBAs at Grand Valley State University. The company is headquartered in Grand Rapids, Michigan, and has 523 employees and revenues of nearly $1 billion per year. CareMed's sales occur in the United States. However, the company imports 80 im of its products from suppliers outside the US. To manage international suppliers, the company has offices in Shanghai, China, and Eindhoven, Netherlands. The medical device market in the US is governed by strict regulations and standards, designed to ensure patient safety. Imported medical equipment must undergo rigorous government certification before it can be sold in US markets. Certifying that imported supplies meet US regulatory standards represents one of the biggest cost drivers for CareMed. Morgan and Victoria have been watching the news closely and are concerned about a novel coronavirus that has ermerged in Central Asia. The new virus, called the Eurasian Steppe Virus 2023 (or ESY-2023), is highly contagious and has been spreading quickly westward from Georgia to Russia and Turkey, China and other Asian countries to the east have not yet been affected. The World Health Organization (WHO) has been closely monitoring the virus's spread. The WHO is working closely with the government of Turkey to stop the spread of the virus, but these efforts have been hampered by the political instability in the rejion and a lack of funding from the international community. If the WHO's efforts are unsuccessful, the virus could reach Europe and the US in 6 weeks to 8 weeks. Morgan and Victoria think that it is only a matter of time before the virus spreads to Europe and the United States. When that happens, Morgan and Yictoria are expectinga major surge in demand for exactly the types of medical supplies that CareMed sells. When that happens, CareMed expects annual unit sales of at least 150,000 units with average revenue per unit sale of $1,000. To prepare for a possible surge in demand, Morgan and Victoria are considering onboarding a new supplier. They have found two potential suppliers: Zoupeve Supplies located in Shanghai, China, and Gute Mefigin, located in the Baden Wuerttemberg region of Germany. Bhuover Supplies (Shanghai) Zhuever specializes in high quality healthcare products. The company has annual revenues of roughly S2.2 billion. It has long-term contracts with well-known US medical suppliers including Cardinal Heaith, Mckesson, and Henry Schein. The company is 1SO9001 certified and has been awarded the prestigious AME Award for Manufacturing Excellence. However, in-depth reporting by the Wali Street Journal suggests that Zhupere is currently undergoing a leadership change that has caused its service levels flead time, on-time delivery, etc.) to drop off. The company's operations are entirely inhouse. Its production facilities AR lachated in the Shanghai FreeTrade Zone (SFIZ). Operating in the SFTZ provides A.ppober.gf benefits to ZWypoye. This includes the elimination of usual export duties - although exports from the SFTZ are subject to the 25% tariffs recently imposed by the US. It also makes it easier for ZhupXHe to maintain quality and comply with US medical certification guidelines. At the same time, Chinese authorities maintain tight control over the SFIZ and therefore would be able to quickly shut down exports from the SFTZ if an outbreak were to occur in China - or if political tensions with the US were to flare. If CareMed were to purchase products from Zbugeve, the likely route would be as follows: Products would be palletized, placed in a container for shipment, and then moved by train a short distance to the Port of Shanghai. There, product would be loaded onto a container ship. The container ship would depart Shanghai and arrive at the Port of Seattle, Washington, in approximately 13 days. At the Port of Seattle, containerized products would be load directly onto trains and shipped to Chicago via rail. In Chicago, cargo would be unloaded and palletized product would be loaded onto trucks and shipped to CareMed warehouses in Grand Rapids. The entire process is estimated to take from 24 to 28 days [See Appendix 2]. Zhueyue has a minimum order quantity of 1 container per month. Gyte Medigiz GmbH (Germany) Gyte Megizjic was established five years ago and had revenues of roughly $750 million last year. The company sells a wide range of medical products. Gute-Medizic has an outsourced production model for personal protective gear, such as medical masks, gowns, and gloves. A network of suppliers in the Czech Republic makes the products then ship products to Gute Vledizic for distribution. The company also operates several inhouse factories in the Baden Wuerttemberg region of Germany. These inhouse factories produce medical devices such as eye and ear scopes, stethoscopes, blood pressure monitors, and other small-scale equipment. Gute,Medizio then ships all products from Germany to customers around the world. Gute Wiedizic representatives suggested that both the personal protective gear and medical equipment are compliant with US standards, although it is not clear whether this is the same as being certified. CareMed has asked for additional information on this point but has not heard back from their contact yet. Still, the company has executed some short-term contracts for a few well-known medical equipment. companies. If CareMed were to purchase products from Guteldedizje, the likely route would be as follows: Products: warehoused in Baden Wuerttemberg, in southern Germany, would be palletized, placed on trucks, and shipped to the Port of Hambure, in northern Germany. From there, products would be loaded into a shipping container and placed onto a container ship. The container ship would depart Hamburg and arrive at the Port of Charleston, South Carolina, in approximately 21 days. At the Port of Charleston, palletized product would be loaded back onto trucks and shipped to CareMed warehouses in Grand Rapids. The entire process is estimated to take from 28 to 31 days [See Appendix 3]. Gute.Mediziz has a minimum order quantity of 2 containers per month. CareMed is primarily a medical supplies distributor. In other words, CareMed typically purchases finished goods from external suppliers and then sells them to customers in the US. As noted above, all.of CareMed's sales occur in the US and the company imports 80% of its products from international suppliers. Still, CareMed does have some options for internal production. It has a small inhouse facility that produces personal protective gear. This facility produced about 10% of CareMed's medical supplies last year. But with an expansion, Morgan and Victoria think that the facility could ramp up production to a volume equal to approximately 50% of the expected increase in sales. Such an expansion would require substantial fixed investment and the redesign of existing processes. An expanded facility would likely be able to begin production in 12 weeks. Relevant Data CareMed has collected the following data to cohduct is analysis of its different potential options. Costs for nach supplier represent the average costs CareMed would expect to pay for the mix of products it would likelv buy from each supolier. Note that the oricine below is per unit. Appendix 1 Carokned Inr colle a wide ranne of nersonal protective gear. medical devices, and other medical supplies Appen Importing from Zhuoruue Supplies Zhuoyue Supplies Shanghal, China