Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Please design a shell and tube heat exchanger. Do calculations from that information. Project Design a plant to produce 20,000 tonnes/year of monochlorobenzene together with

Please design a shell and tube heat exchanger. Do calculations from that information.

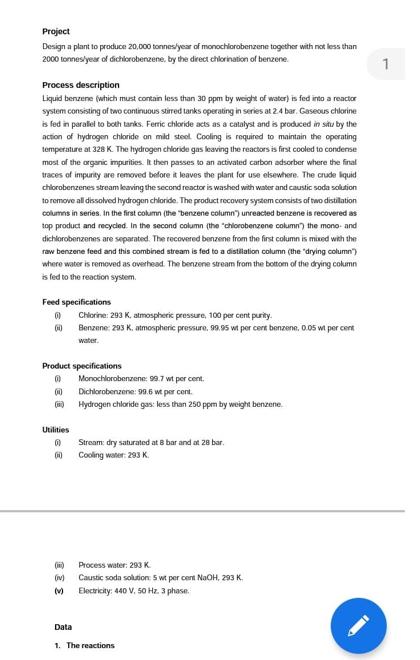

Project Design a plant to produce 20,000 tonnes/year of monochlorobenzene together with not less than 2000 tonnes/year of dichlorobenzene, by the direct chlorination of benzene. Process description Liquid benzene (which must contain less than 30 ppm by weight of water) is fed into a reactor system consisting of two continuous stirred tanks operating in series at 2.4 bar. Gaseous chlorine is fed in parallel to both tanks. Ferric chloride acts as a catalyst and is produced in situ by the action of hydrogen chloride on mild steel. Cooling is required to maintain the operating temperature at 328 K. The hydrogen chloride gas leaving the reactors is first cooled to condense most of the organic impurities. It then passes to an activated carbon adsorber where the final traces of impurity are removed before it leaves the plant for use elsewhere. The crude liquid chlorobenzenes stream leaving the second reactor is washed with water and caustic soda solution to remove all dissolved hydrogen chloride. The product recovery system consists of two distillation columns in series. In the first column (the "benzene column") unreacted benzene is recovered as top product and recycled. In the second column (the "chlorobenzene column) the mono- and dichlorobenzenes are separated. The recovered benzene from the first column is mixed with the raw benzene feed and this combined stream is fed to a distillation column (the "drying column") where water is removed as overhead. The benzene stream from the bottom of the drying column is fed to the reaction system. Feed specifications 00 (6) Product specifications 00 (0) ( Utilities 00 (0) () (iv) (1) Chlorine: 293 K, atmospheric pressure, 100 per cent purity. Benzene: 293 K. atmospheric pressure. 99.95 wt per cent benzene, 0.05 wt per cent water. Data Monochlorobenzene: 99.7 wt percent. Dichlorobenzene: 99.6 wt per cent. Hydrogen chloride gas: less than 250 ppm by weight benzene Stream: dry saturated at 8 bar and at 28 bar. Cooling water: 293 K. Process water: 293 K Caustic soda solution: 5 wt per cent NaOH, 293 K. Electricity: 440 V, 50 Hz. 3 phase. 1. The reactions 1

Step by Step Solution

★★★★★

3.48 Rating (165 Votes )

There are 3 Steps involved in it

Step: 1

PEOPERTIES USES MANUFACTURING PROCESS The basic principle behind the manufacture of Chlorobenzene is ...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started