please don't explain the scenario help me with calculations for question 2

please don't explain the scenario help me with calculations for question 2

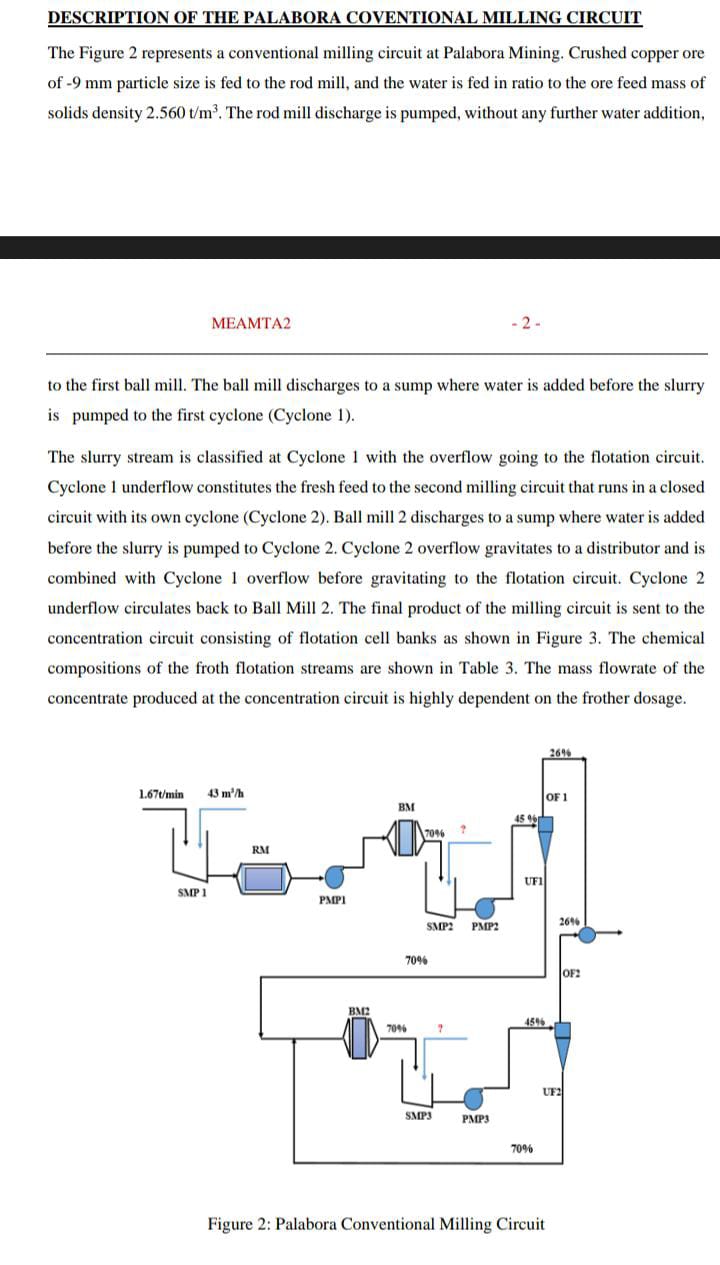

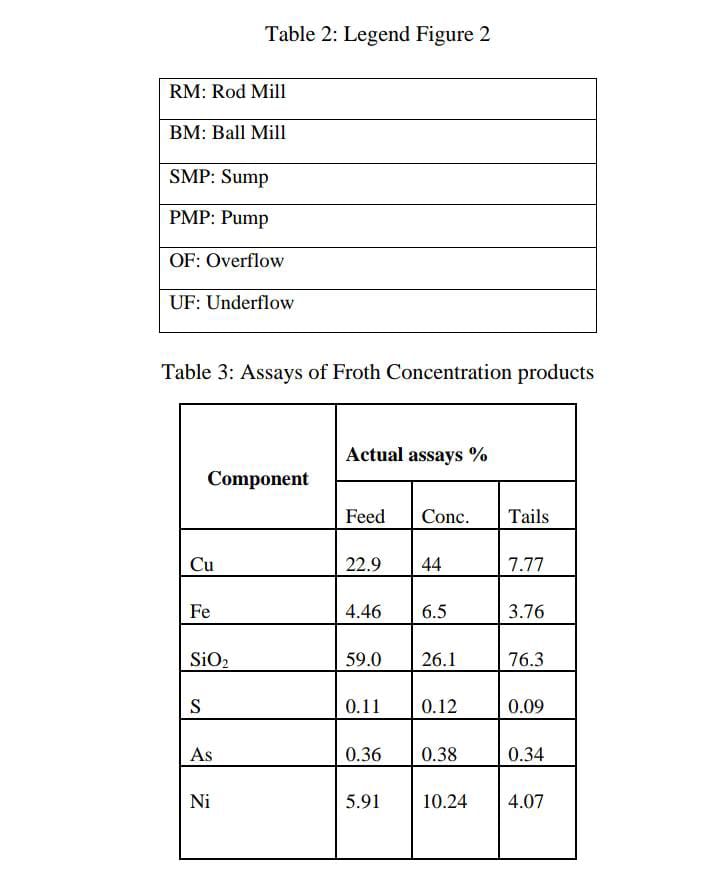

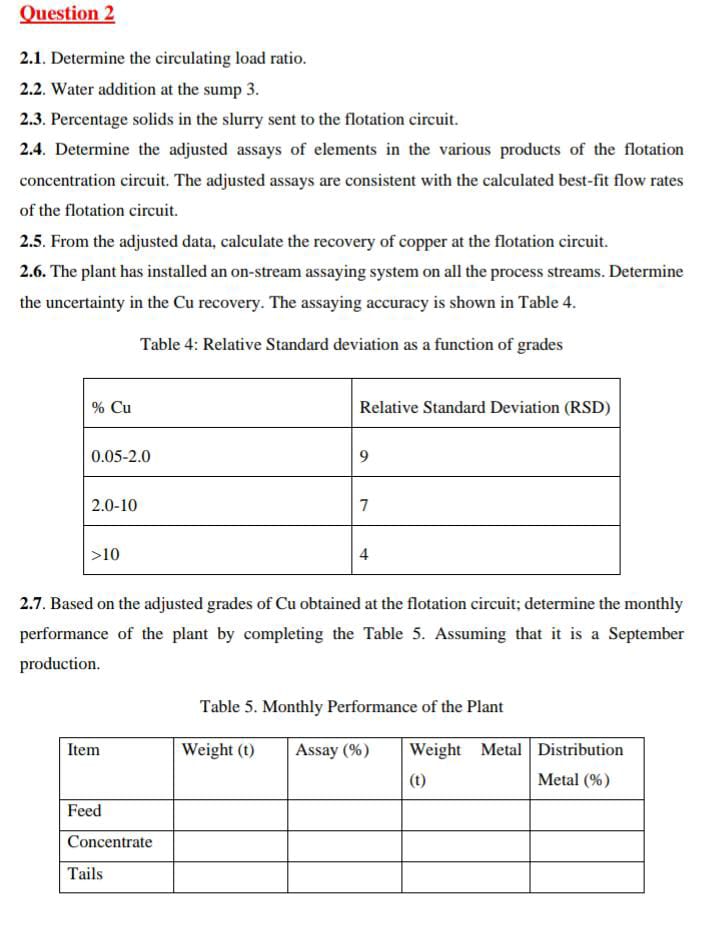

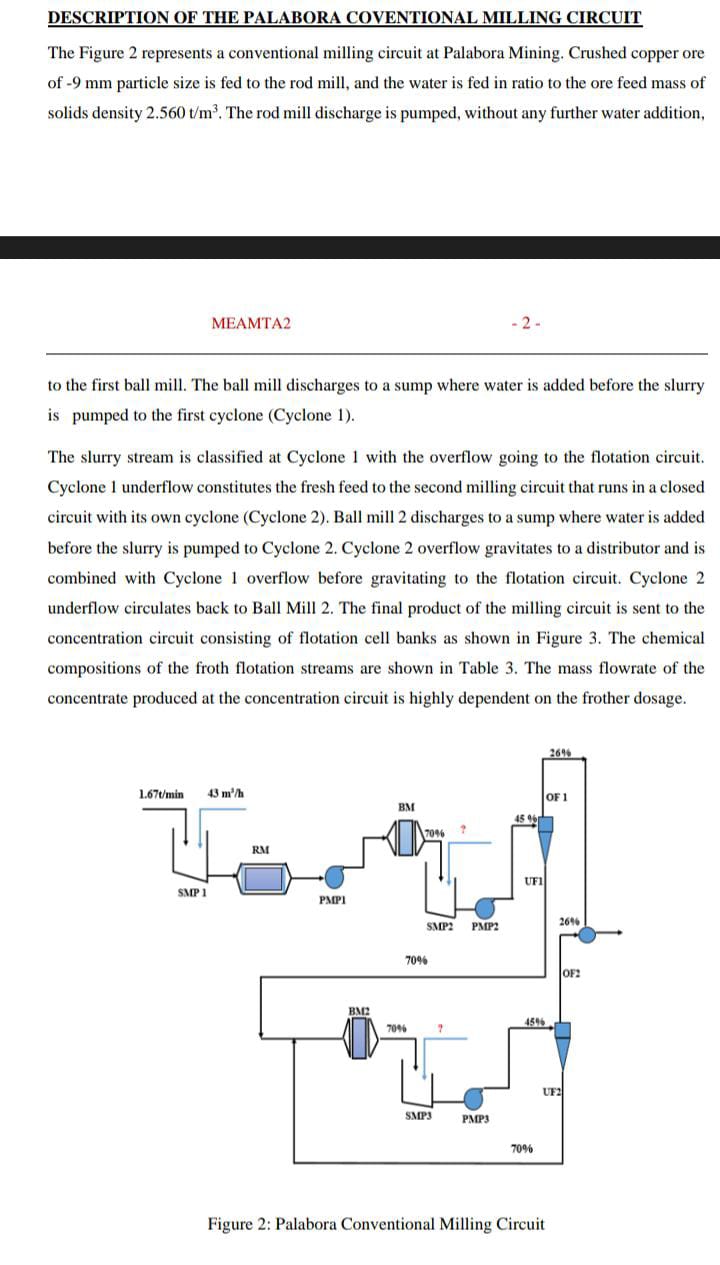

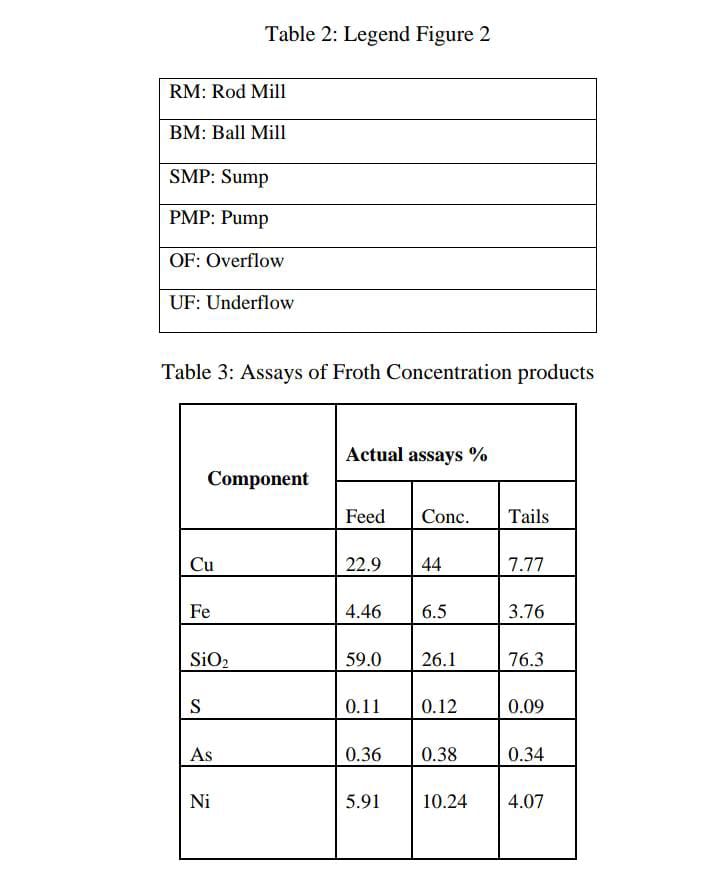

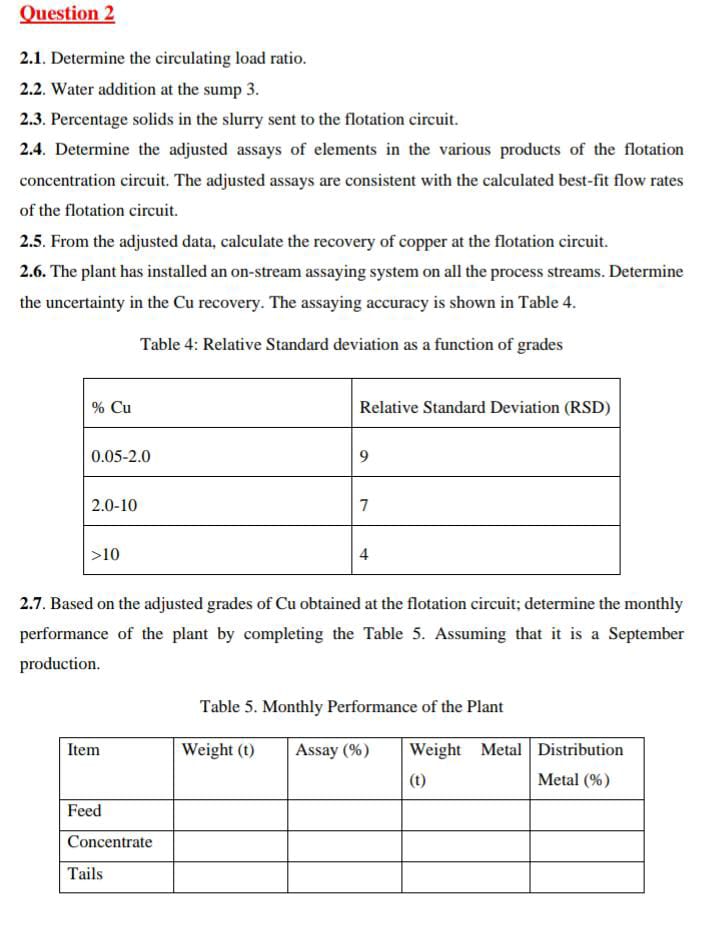

DESCRIPTION OF THE PALABORA COVENTIONAL MILLING CIRCUIT The Figure 2 represents a conventional milling circuit at Palabora Mining. Crushed copper ore of 9mm particle size is fed to the rod mill, and the water is fed in ratio to the ore feed mass of solids density 2.560t/m3. The rod mill discharge is pumped, without any further water addition, MEAMTA2 -2 - to the first ball mill. The ball mill discharges to a sump where water is added before the slurry is pumped to the first cyclone (Cyclone 1). The slurry stream is classified at Cyclone 1 with the overflow going to the flotation circuit. Cyclone 1 underflow constitutes the fresh feed to the second milling circuit that runs in a closed circuit with its own cyclone (Cyclone 2). Ball mill 2 discharges to a sump where water is added before the slurry is pumped to Cyclone 2 . Cyclone 2 overflow gravitates to a distributor and is combined with Cyclone 1 overflow before gravitating to the flotation circuit. Cyclone 2 underflow circulates back to Ball Mill 2. The final product of the milling circuit is sent to the concentration circuit consisting of flotation cell banks as shown in Figure 3. The chemical compositions of the froth flotation streams are shown in Table 3. The mass flowrate of the concentrate produced at the concentration circuit is highly dependent on the frother dosage. Figure 2: Palabora Conventional Milling Circuit Table 2: Legend Figure 2 Table 3: Assays of Froth Concentration products Question 2 2.1. Determine the circulating load ratio. 2.2. Water addition at the sump 3 . 2.3. Percentage solids in the slurry sent to the flotation circuit. 2.4. Determine the adjusted assays of elements in the various products of the flotation concentration circuit. The adjusted assays are consistent with the calculated best-fit flow rates of the flotation circuit. 2.5. From the adjusted data, calculate the recovery of copper at the flotation circuit. 2.6. The plant has installed an on-stream assaying system on all the process streams. Determine the uncertainty in the Cu recovery. The assaying accuracy is shown in Table 4. Table 4: Relative Standard deviation as a function of grades 2.7. Based on the adjusted grades of Cu obtained at the flotation circuit; determine the monthly performance of the plant by completing the Table 5. Assuming that it is a September production. Table 5. Monthly Performance of the Plant

please don't explain the scenario help me with calculations for question 2

please don't explain the scenario help me with calculations for question 2