Question: please give solution to this whole question 14 chapter 6. coarse instruction 161 Why 1. Usip 14 TMC ABC Coily for the VEI. MES fondu

please give solution to this whole question 14 chapter 6.

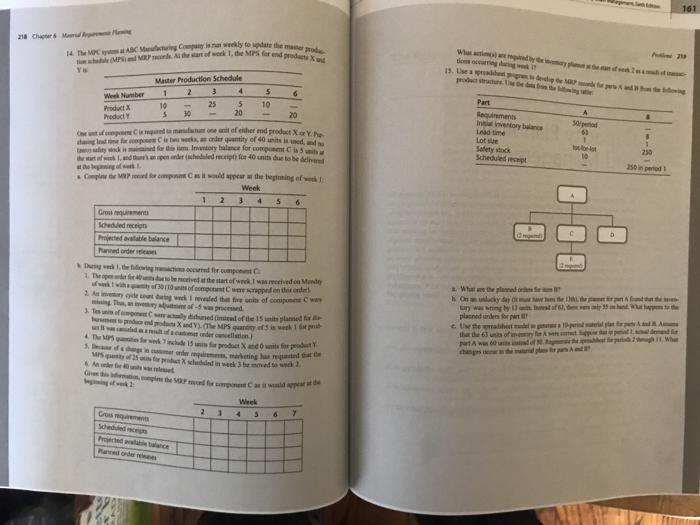

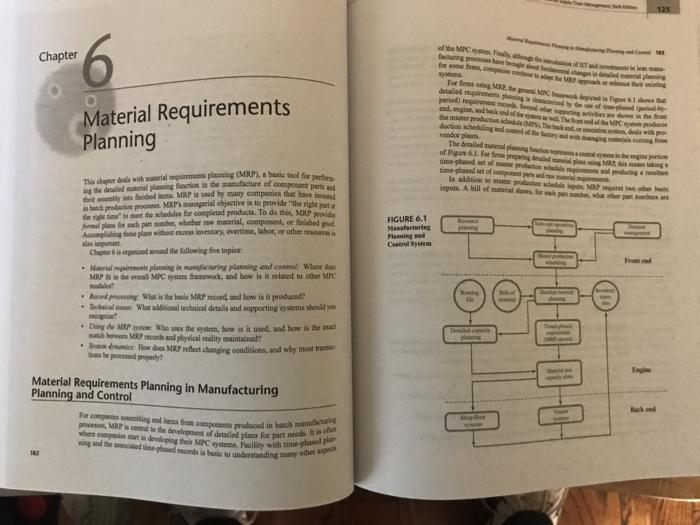

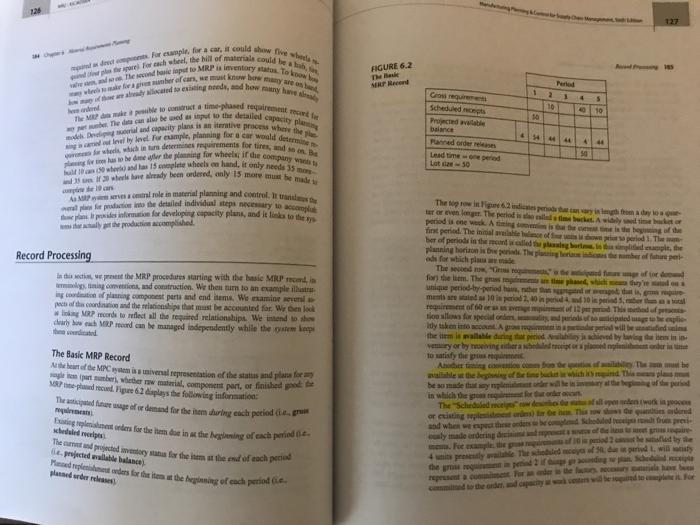

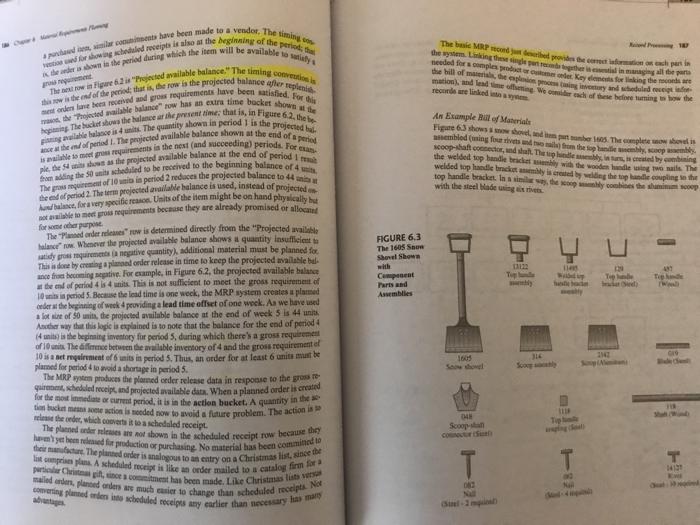

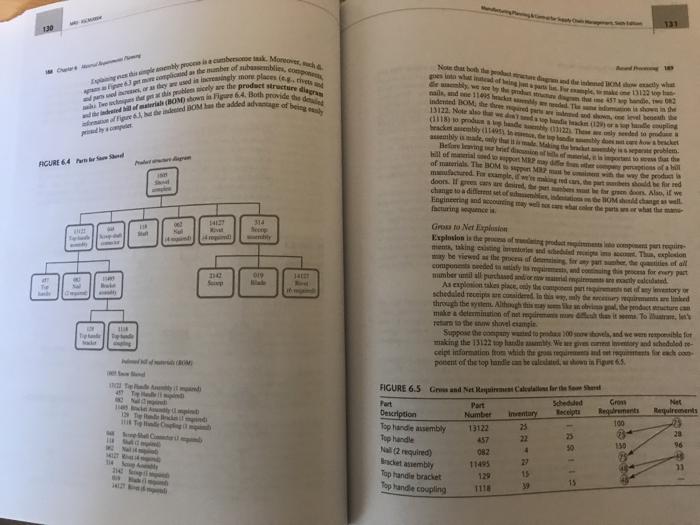

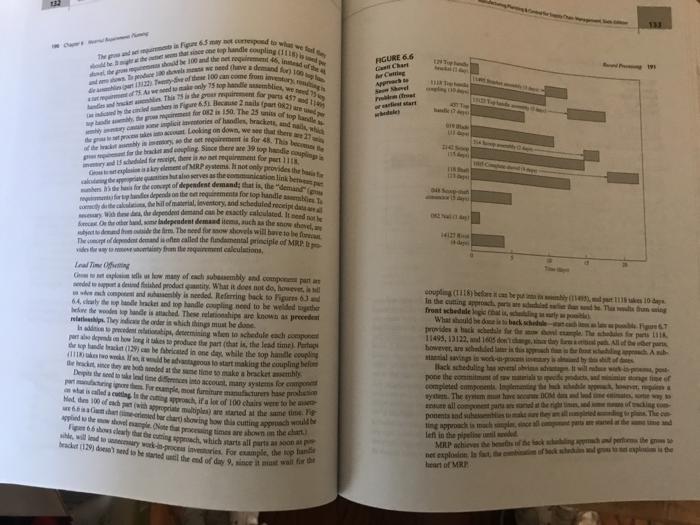

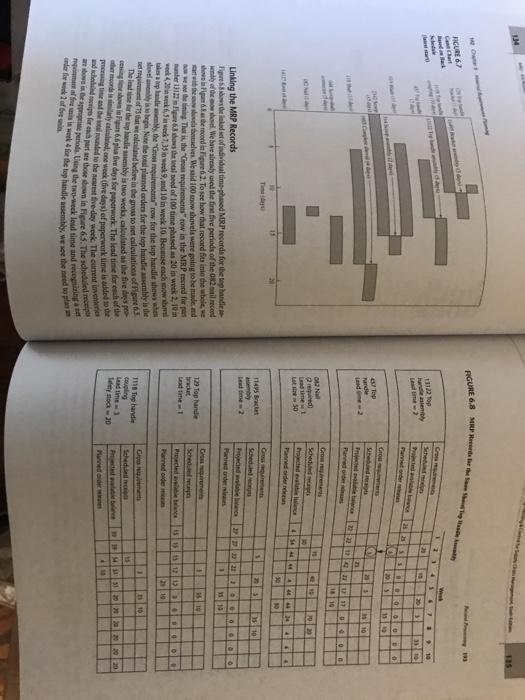

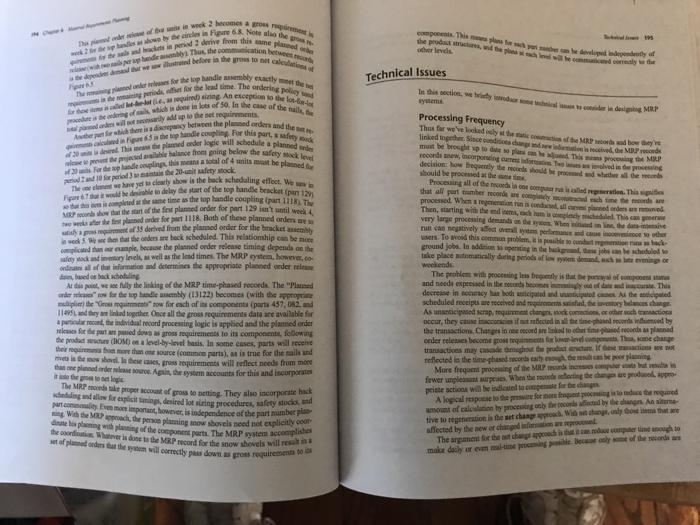

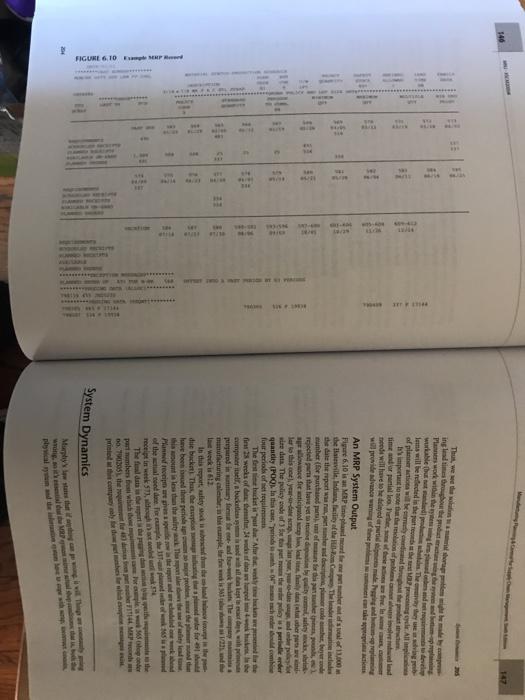

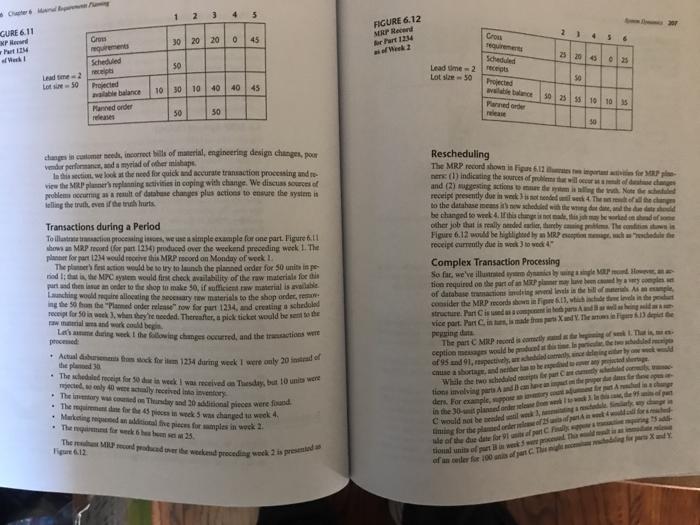

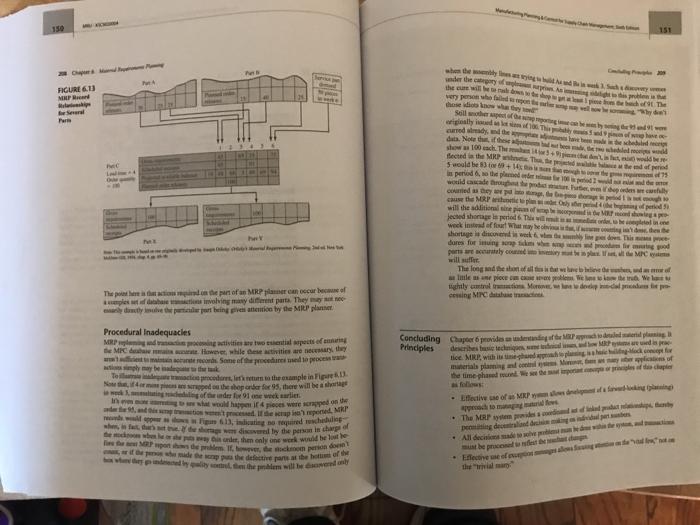

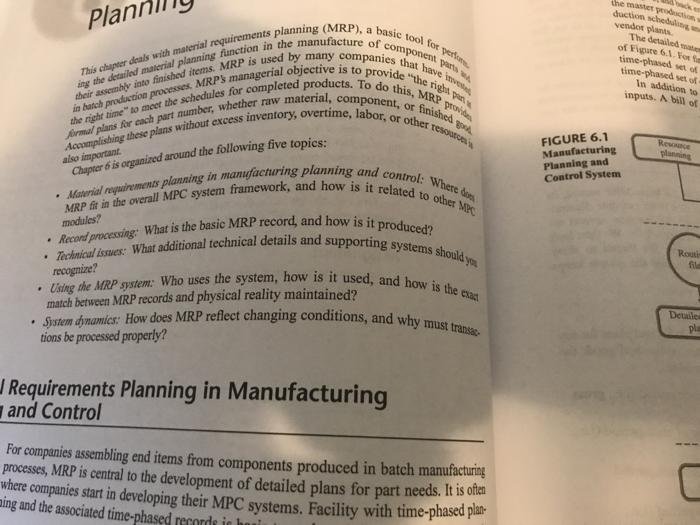

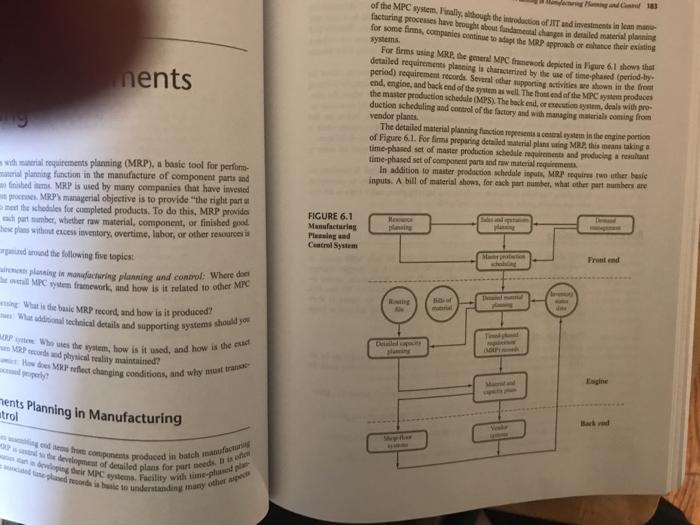

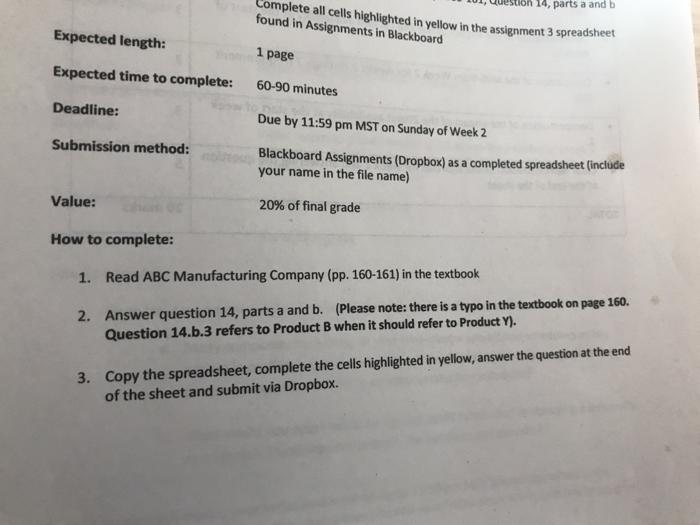

161 Why 1. Usip 14 TMC ABC Coily for the VEI. MES fondu Ye Master Production Schedule 1 2 3 We Number 4 5 6 Product 10 25 5 10 Product 5 30 20 20 Part Time Che witni ured u meniliste unit of ethered product dependentity of 40 medad wedd try Slance for competish ber stated pet under helled ceipt for 40 unit due to be del ting - Complete med for empormal deur at the beginning of the Schedule 250 1 Week 3 4 2 5 6 Gourmet ded Pred le balance Mandarder What they Only sy way planned anden for the 15 al the startowed Mende 30/ towe wrapped on the orde 2. Are cate of compet od of war med mera the school ,kaning le de hemmet Compiute Prosedur pets wmp *** Week 2 3 6 7 ded Merder 125 MC yum. 11 Chapter -6 sy Material Requirements Planning disi drag powe od po Coco dhed ghettory There are of H 6.1. for firms Is de FIGURE 6.1 Masalature Planning and Car System w the dated serial planning faction in the manufacture of compone per This is with material pagincertentie planine MRP buic tool for perform hot pretio promenagerial objective is to provide the right perta the meat the stabiles for completed products. To do this, MORP Molde for alle for chartet, her row meal.componenter finished put Accomplexes inventory overtime, labor, or other do important Chapter the following five opier Marilliginine planning and Where does MRP f the Mystem track, and how is it related to the MIC module Records What is the balie MRP record and bow is it produced Te Whitechnical details and supporting system told you MP Who we the system, how is it used, and how is the na Pundyycal reality maintained? How does MRP effect changing contitions, and whey muuttum the bedry renanted Material Requirements Planning in Manufacturing Planning and Control camping de produced in hac , Mistral to the development of detailed plans for partneri where it is in the others, Pacility with time- pede godt med disse to understanding many other as 18 127 FIGURE 6-2 The MATRA 1 2 5 10 10 16 por cumple for a car, I could show five For each wel the hill of materials could be a were car, nuwe are on the ende loputto MRP in inventorystu. Takowe and existings, and how many The Melo completo The need out to the detailed city plan del Deady stive prices where the umrlo by For cumpe, planning for a car wall det be which in denen purements for tires, and so on. B go beder the planning for wheel if the company w Nowa 15 wheels on and only needs 35 mon we ready been ordered, aly 15 more must be made A MPV role in material planning and control the balance Leade one pend Lot 50 The do te pida el plan de production into the detailed individual stepaneey to accom le ponides information for developing capacity plans, and it links to the Record Processing In this we were the MRP procedures starting with the base Murcin and construction. We then to an example ist ing planning component parts and end items. We mamine pochote cardine and the relationship that must be accounted for. We en look W MRP moord w reflect all the repaired relationships. We intend to show download MR moord can be managed independently while the gate pe fint period. The initial off bere periode is the man wed the bar planning hoon is wide. The power The med unique periode periodo di me mense dispod 1. 10 in pol pieder region of 12 Theod tool for specie di procedat Idy taken in adapted will be attende the term is mal during all chined by the line very or by moving the to satisfy the pour Acco with me wallet the begin be so made that my poder in which the gromne The scheduled modelos full Gehe This ownloaded Schoaded from pre and when we expect the des ay made ordering The Basic MRP Record Albert of the Miss universal seposentation of the status and plafon na te peber, veter x material, component part of finished patte e die 6.3 days the following information These few of us demand for the item during each period (ie. Bunge for the main at the beging of each period scheduled The procedimentary as for the the of each pened povjected wallste balance Mand replenishmet verders for the item is die beginning of each periode real 4 is presently the scheduled for a period I will wat Sche The buske MRP recond the provides the common per needed for complex probat reader anderen the bill of material de la entry and wheband mation, and ind time offering Wear Te day. 8pc bave been made to a vender. The ordigheded receipts is also at the beginning of the period, tha ided the period during with them will be available The row for 2 "Preted available balance. The timing consis monda beard and Juirements have been satisfied for this theed of the period, that is row is the projected balance aer replenish The Troyected me balance tow has an extra time backet show the gewThe quantity shown in period is the projected The how the balance at the went time that is, in Figure 62.thebe chord L. The procedallable balance shown at the end of a period se sont is the best and acceding periods. For pich the projected available balance at the end of period i an adding the scheduled to be received to the beginning balance of 4 The roof 10 la period 2 reduces the projected balance to a uw bara very specific Units of the item might be on hand pocaithe As Example lofMaterial Fine 3 shows and more. The complete with membiding for its del from the phone, open copacometenda. The epidemins, created by haning the welded handed with woodland was the welded top hentais rudy willing the top lande coupling in the top handle bracket la siyo with the steel Made inget FIGURE 6.3 The 1605 San Sharel Show with Cempat Parts and Asemblies Tube 19 Tip w ho het nilable to meet prot requirements because they are already promised or allocate for her purpose Themed andet des" w is determined directly from the "Projected wallable Malane row. Whenever the projected available bulance shows a quantity insufficient atsly pro nequirements a negative quantity), additional material must be planned for This is done by creating a poder release in time to keep the projected available bal. ance from becoming seative: For example, in Figure 6.2, the projected available balance at the end of period 44 units. This is not sufficient to meet the gross requirement of 10 is period 5. Because the lead time is one weck, the MRP system creates a plamed order the beginning of week 4 providing a lead time offset of one week. As we have used lote of Suits, the projected available balance at the end of week 5 is 44 unit Another way that this lopie is explained is to note that the balance for the end of period 4 sanity is the beginning inventory for period 5. during which there's a gross requireme of Ounits. The diffemme between the wallable inventory of 4 and the gross requirement el 10 is a not requirement of 6 units in period 5. Thus, an order for at least 6 units must be planned for period 4 lowolda shortage in period 5. The MRP system produces the planned crder release data in response to the groot quirement, scheduled receipt and projected available dita. When a planned order la created for the most immediate a current period, it is in the action bucket. A quantity in the than lucht metna rete action is needed now to avoid a future problem. The action is The planeers shown in the scheduled receipt now because they by herdaction of purchasing No material has been commined to dicture. The planned oder is nous to sentry on a Christmas list, since the partma has been made. Like Christmas ist w ist. Aschede in order mailed to a catalog firm for mandarden planned anders as much as to change the scheduled receipt. No converting planned to scheduled receipts any earlier than necessary las man 1605 16 the one which wascheduled receipt T T 13 131 Encuene More thenber of subassemblin, word ingly more places. This puble only the product structure dans BON 64. Both provided BOM dead ago Now the hing pate 012 dhe past two ma 11 how Indeed Bo Beheer 137. Newlands (12 de coupling un padel y seeded to pro wade the day at how beet wa Miten Below in the motore actor of The BOMM data chito di BOMshawl RCURE 64 Sud per problem pas afa the way he pod en doen. Also, if we he Groot Net Explosion Explosion is de produto 019 compeded to stay with me mumber will puthammadyace As explosion takes place on the comparte day ory scheduled receipts de la tierrants are linked through the went. Although the pendantur make a determination of not mean tim. To re the shovel ciampie Suppose the company top 100 bove, and we were reposible for making the 13122plasm We presentary and scheduled to ceipt Information for which the ground fordon ponent of the top landies be clear, in Pipe 6.5 437 FIGURE 6.5 Grand Net Reims Calculations for a som Share Part Part Sched Gron Description Number Recepti Regulaments Tophandle assembly 23 100 Top handle 22 3 082 11495 22 28 he required) det my Tupande bracket Tophande coupling 1118 39 133 RGURE 66 phandle coupling (1118 de a thing Bed cheddon 100 from 75 tagad, Cutie there is for 150. The 25 ans of the more of handles, brackets and which Me Locking on down, weet the het is for 4 Thia for the boding. Since there are op die ou for the requirement for part 1 MRP not only provides the thao frodestatis, the demande for dependenta for top unde este We depende demand on be exactly calculated. It send the coupling (1) bear In the cutting approacia froatchedulele cha kecen Ou testerandependent demandien, ruch as the street The pendent demand often called the Bundestal principle of MRPUS udposted on the im Tender now shows will have to left y require alculations Leal Time tapos www many of each bombily and compare part dowded shed product antity. What it does not do, however, who bella meded. Referring back to Pin 64 the planendel and handle coupling send to be welded the See the woods and sched. These ships are known as precedent They now the ander is shich things must be do It is recedenti, dening when to schedule achet parte de los produce parthat the ladies the plane (129) como se to the couple bested in one day while the top handle coupling Belediye ale to make and Depende dieren ime, any systems for men cump, film has pro locales con brachial of 100 chains weet Wat te dwa part (with propriate multiple are started at the same time de las ertestod for chart showing how this cutting apprzech will be pl provides a back 11495, 13122, 1605 de Black scheduling him it will pone the commitment of dawno apital campoomil Irimation wych. They DOM doo all compete onda tenging ponents and see The ing pad is complaint le in the pipeline MALP shinaatulatatatatti pertine Fedewhat being peach, which starts all parts prong times are on the car Wada 12 de andered the end of day, all the wilt work for emple, the place of MRP TAS EGRE 6.8 MB CURE 6 Chat 11 . 6 . unde 23 3 is 10 ad 00 . 19 al UN Late1 L50 020 RI ta 14 4 50 10 11495 Brac 1 3 1510 bilo 10 ao 1 129 Top Mande + 1510 endimet Linking the MRP Records Predstof individual time-phased MRP records for the handle heid Webare already well fint five periods of the 2 mil record dows crecord in Figure 6. To see how that record fit into the whole we Weid 100w shovels were going to be dead edhe ng That is, the roulements row in the MRP meord for manter 1333 6.3 teeled of 100 time phases 20 in week 2. 10 m 20,wed 1.33 10 in welk 10. Because cachowa the Grow more"row for the top handle shows met of Statwaleted before in the grows to net calculations of Figures obepin. Note the val planed anders for the top handie musembly is the The line handie bly in two weeks, calculated as the fire des per in Polphabe days for paperwork. The lend time for andre er mere end at least one sede e dos ef paperwork time as added to Pannede 16 1118 Top bandie ung de stock - 30 Sched 20 20 and for those dan in her 63. The schede these day week. The current bibend ung the week loading and recoge mathildebee the coeperent. The developed dyr der levde Technical Issues Dowk 2 boca by the Nethe hace 3 derive from this used di Thu the best The theophandel ently dore latine. The ordering po Gre, Acepto one in 19. In the of the the wadi penetrarents with the there is any the pludonders and the ut the top andle coupling for this pur, denk The order age will chedule a planet halance from ping below the safety sched Fordplade opling this bool of the planned we have yet to clearly show is the back scheduling effect. We for periods the 20-cility Mock wild we de tu delay the start of the top handle becket (pur 123 sa de Mulher of the four planned order for part 129 fint until week two weeks where is planned anden for per 1118. Both of these planned anden some of 35 derived from the planned order for the bracket Cher that the orders are back scheduled. This relationship can be mite emple, because the planned order release timing dependa yoksyinels well as the ind time. The MRP system, however, to efth information and determines the appropriate planned andere beds back whaling All e Mly the linking of the MRP time-phased records The "Plased for the toplande sembly (13122) becomes with the prop melletter tow for each of its component parts 457,082. 1120Land they are linked to the Once all the gross requirements data are available for a particular round, the individual record processing topic is applied and the planned order mener det des gross requirements to its components, fong de produc (BOMO level-by-level basis. In some cases, parts will recent there that one source one parts), wat is true for the nails and met woede er requirements will reflect needs from more the planned andere Aker system accounts for this and incorporis The Mamen nike proper account of prosenting. They also incorporate houd soliding und die feit desired for turing procedures, afety codes und pertama memporal, lower, is independence of the partner Wake penge beves need not expliciter her when I done the MRP record for the snow shovels will rema water enters that the system will cretly pas dewels grans requiremena do system Processing Frequency That way to the Madhow linked as recived, the MP code a bebe proche ! recordement viewer decide the more would be promote Processing all of the modern. This that all part sumber mondatoto processed. When som Then starting with the end, damchisa very large procesing demand when he na stively complet we. To wond this common problema pead ground jobs. In additing in de school take place atically during flowych weekende The problems with cering lestry is that the pa and neede expressed in the model. This decrease in concha bodi uticipated the led scheduled receipts are received a message other characta Asunted serp, tequirement can make occur, they can dilte meghaty the transaction. Changes in conded to create and onder release become rose quando home transactions may mga pandai reflected in the time has come per More frequent processing of the MRP de Income fewer plures When the minded prime actions will be indicated to come for behan. A logical respecte al poco tigured amount of all by proceso de reconsided by dan Ans tive to repeat the change. With the afected by the new arched The arpent for the not change mal daily or comme progress of the word of the opport The MRP stem accomplishes daractered for very curate computer records and to pred Seen dan de an occasional regeneration to de pened order is my be frustrated with these front ng my walcow of commended to OF DEVOL The ma The cost canapetost change in its hypersensitivity, Bucketless Systems To win the proofgarted to theme of time buckets. When the back cat mall the problems are reduced significantly. However, smaller back , which can and computation cost. Aber MRP is the case and doe dates for each requirement, scheduled raadpandandet. The reports are printed out on whatever his Bucket MRP area bener way to the computer. Above and beyond that As many firmsplay alithaal Safety Stock and Safety Lead Time Carrying out tuled compond plass tillid by closing teada and safety lead me in the MRP od. Salony w a butterflod above and asing any mode for the top de company faluty lead time is procedure where shop orders or purch den www.healed to menor periode before the Safety stocks can be exposed. There projected wailable under pero. To incorpone y almohad (planned to be received a roapewolde s necesary Figure how to be one-week safety lealtime Notice led led dates are changed. Sulety lind meist Both safety and all time we can be ously. However, borbeid that aintadrilanadiantara they need to be received, in fact, the way and safety lead mes effectively, med et Scenes y are not well understood worden aus te laten werken will try to get our Abone of you wality od whitput will be required to meet corner Safety stock tends to be din MRP na siste probleme where some milf mappen usage is a frequente de los de others who the major incity is the timing her to form af buys from a vender homines delivery ty lead me prinde belle than safety stock iding by dates the sprach allows beter maintenance of lead time of iets and provides more precise med in the preach is consistent with state-of-the-art software, many firms now we bedenisystem. The major addition is that the planning cycle her is balles. That i, planeeridas necessary, not on a periodie schedule, and the cells botened Lot Sizing Is the ovenample of Figure 6.8. we see a fixed lot size (50 units for the nails and the sole procedure. The lotine of 50 for the nails could have been someone tale of podle of the result of calculation. The time-phased information can be used in combined with other du to develop lot sizes conforming to organizational od We might ach the conclusion, for the top handle (1118) in Figure 6., that desirable to set up the equipment for 4 parts in week 2, und again for 10 parts in werk we'd combine the readers. The time plased record permits us to develop such disrufe Het slot wil only way the net requirements for one or more periodi Several fortal procedures have been developed for lot sizing the time phased requires aperte el curying inventory longer. In many cases, discrete lot sizes possible with Mo more poing as fuel et niees. Compare the residual inventory or malls a weckt 4 5 6 7 FIGURE 6.9 MRP Record with Salty Lead The 1 2 Part 129 Grosi requirements Top handle 1 15 18 with of this Figure 6., for ople bracket ead time 1 Lottorit Scheduled cepts Projected As finance the foot locha sabo sple-minded since it doo der yheder physical factors. However, hatching planned or Sebed nem level of the bill of materials cascades de level will increase the next level in the product dhe bill of material. This is expecially the ed. This can be good to some extent for compondant When this is the case again lot siring may he appropriate riy 15 15 15 12 10 Sety lead time1 balance Planned order releases 141 Low-Level Coding wert 04, we see that the rivet (part 14127) The Ponderow for complex where will be used dot as posset sont at there we arquirements for the rivets (14127) frede On the top and record for this con part before the record pred te wary here powing de wet. Become mes to the new Con for penge the form planeerders Testing y amigo femeile che mitter The press they were he problem for penders, the to meet special mediabetes pendant of the indend BOM. By convention, the top final assembly els he pre requirements and he accumulated, the computations must be redone metod a level. In our comple, the snow where would have a low.level code oro Figuere te dy are pret the low-level code numberThe next level down part sumber 45 013, 11495, 216,013 and 14127) we low-level coded 2. Note the common partne) just hem ooded as nel 2, indicating it in used lower in the product structure. The higher tulee end, the lower in the product structure the purt is used. Consequently, the lake led eipe part indicates the lowest level of age and is the level code sed for that put Wenchermple when part numbers 129 and 1118 are codul level 3. The level code wiped to any part number is based on the parts unope in all prod. red by the option One low-level des e established, MRP record processing proceeds from one level ce the starting at level code. This ensure all grou requirements have bem puses puter its MRP record is processed. The result is planning of com paper ordinated with the needs of all higher level purt number. Within a level, the Mga typically done in partumbet sequence. Pegging al ter oprettes for a part to all the planned onder de demand tu tad te requirements. The persing records contain the on the depased record. For lower level part de migle corti e specific ter onders to be satisdied by de pegel planned orders of Sigheroveltum powden the part is sold as a service part Service Parts Service par demand met de ti not to be understand. The worpus added directly into the po tepe view, the rice party and the source of illos The low-level code for swell porn part as well as de och at As actual service partner poids will These can be partially buffered with locally and in vicepartme) or by the Molly records, expected shapecondi bestified to wear Condominium perhaps be met with lots is needed to butentifs Pagudpupugh the MRP records from a lub de la sent the reverse of the redure, unbers of all in on which the part compared to wher-ered date. Where used in www whered file. Peting shoes te pociis gross requirements in each time period Thomaerial problem all the way up the Planning Horizon In Figure 6 de fotode for period 4 grow our in mponding room This proces falha 1149) Firm Planned Orders The concord for an india ped for berber Theref donderdagve take place in the last The set for his This is a les and his (put idle andere cathered more on ein wedd Scheduled Receipts versus Planned Order Releases 3. Ayew updates would be reaching A medending of MRP require knowledge of certainly differences between chamada planned and we dech ofference before the ent, whereas the planned onder is only a platefois de to ung the late Ascheduled receipt for purchased purchase and which is a forma comitent, has been prepared. Sumiy herritards there an open shop order. Roma ale anaposebe specifically committed to that order to longer for the des. One major rent of this distinction, which bei Figure is the planned andere explode grossequirements for componen stocks 4. Reconoci od 5. Tindley precis 6. Uning In the mods for the precong This be bewMP nestly 1. Indicateurs, depende plane's job I had the open oder den Ada ben the fooing question: Where would a scheduled recept the up hede (13122) in Figure 6.8 of my 20 units in week he reflected Food for the comporte (457,082 and 114957? The answer is nowhere Schedule weet lected in the current feed for component parts. For that scheduled receiptist, the component parts would have already been assigned to the shop onder penting the scheduled foodipe for part 13122 and removed from the available of the comments. As for MRP is concerned, the 20 part 457.40 part 02, und 20 per 118 The other way to becoming 20 part 13122s. The 13122 di proces, the comparecords Order Long Onder die process of www orders. This procen la promesses in the time period, the action hodet. Onder de sched led recreeting them in Odegisting of the und purchase orden doing these deshen hedelme stockroom Actu time, he was tory and eliminate the scheduled Poola pening have to be carefully defined to all are property pro The order indicated by MRP alfonso darts and safety stocks willing. We wird lo-for-lot proaches and faedo Aleppo with wareness of the implications of the leas Forn, alles be aasaiyyanaparilalar taletaintamil afety Macky he is the action bodist When an order is sched, try to includes flar omp and other proces. The typical come per for yield ones that was the order boven quired to effect poodcouveronden, hindadeg, the shown on the shop onder die het beroestyle cur during production Using the MRP System littiin, wedi critical aspects of using the MRP system to ensure that MRP ested with physical flows of material The MRP Planner The part det inobed with the MRP sen outputs are planner. The typically on the plane pinventory control, sed purchasing departments. The es love the permally for making detailed decisions that let the material mories trong terpent. The age of discrimin is carefully linked to us, without higher edhe ratim, ey med den plus de end items delined for customers. Their action Coop MRP chance of third of partumbo murod portid election par West Coatia Allocation and daily Checking Acmapdeal attaintarad larly in leaching that only check for the cury wr wow boven wat wie 30 31 pened the check of part 02.30 of 11.10) MRP 1 1. Recorders and when den Ma Pattadatay 201 oddelby the cor, in me The act of corpo pertanto the partido be the new the dhe lyer, with differences gecede at have been red, but whose componen Ate walay ng tickets are typically and digitale for a specified to probe y action the shop order to be delivered to parti 1. Aty of een where la med paalPrimps.o become the pain mil samayal checking ette e sheh promet Wieland lace is reduced accordingly, Arany continue physical rock picking are type of anderen hoop The may hally on hand should much what por este plaats allocated. If they don't much corrective The di un facilitates inventory counting and other procedure form gn Bottom-up Replanning Bulamin Exception Codes Explore Montesparate the vital few from the trai of the control and the Mystem is functioning Com ning pay 10 20 percent of the partners will req posetion codes are in two nel corries. The in helpos, includes checks for des bound the planning hot than check valid part numbers, the decided forway. The second part of exception codes directly supporte MILF, Incided on the following is of exception (action) Wednesday of the Thief ping this site the only of the 10 bed the 2 made from this, hed The polysis of the 10 de without ting i per mowe should work with the work This should be done if we were the data is the change because the 10 bovenwold fylkesplode ser parte paret the model fly Tweed There may, we heart med during week 4 Solving been with appling me of the following them and the MEP.ph det 1. be an immed to the maibh et une which leader is wide most immediate time period die openport may planned anders two to three periode wded ladder factors while there's sometim 2. Opere di present timing and or amount for a scheduled mees saam da se pode exits thu of the purements in the planning here. This meg cheduled for it is al 2 2. Onder mot til for the best lead time home fatihaha123. The planned for the would be plus cedre delen The e-sektowanie we artikel med to be too carly and should the and feel proper copy poorities. An up at bildet Pure 6.1 Thu 57 op de Anak delay is also a few the Nepiled - hled to have becerdin punct Addroskil weck Anthet op onder de depend 14 instalia Thebe made ww wieder www.The statist A of plant will be dorp oost sed to be di yal del gb TIT 12 An MRP System Output Fly 6.10 MRP at 11.00 the date the report werden, number for purchased the ah rejected to have yet to doby a ods we find a hide the wind Jer to this you want wie data. The policy de quantity (POQ. In this case, whom for periods of nereye The studere de fin 2 weeks of we well the competel, de prejured in my face and they and werk is 612 In this report salut de la web der due back. Thus, the cos bet edhe peripes this is less the way. The Planned to help FIGURE 610 MHP The fu dati Blog der 6713071714. Moh System Dynamics 1 My php 1 2 3 4 5 Crow FIGURE 6.12 MRP Red for Part 124 ok GURE 6.11 WP IM 14 30 20 200 45 320 o 25 50 men Scheduled Leade med Lot 50 Projected Lead time=2 Lot 250 Scended eg Projected so 1030 10 40 40 45 5625 10 10 Manned order Parede 50 50 so changes in customer needs, incorrect bill of material, engineering design change, por vender performance, and myriad of the shape latin, we look at the need for quick and accurate transaction processing and to view the MP planer planning activities in coping with change. We discuss sources problem cum reult of these change plus actions to ensure the wymi talling the trutleven if the truth hurts Rescheduling The MRP record shown in Figaro ner (1) Indicating the worces of the wild and (2) penting actions made me the Ne receipt presently doen wat is de 4. The to the database methoded with dan be changed to work 4. this changes offre other job that is really ended with The conditii Figure 6.12 would be highlighted by Mediathe receipt urmatly due is work to work Complex Transaction Processing So far, we've illud y dynamicale tion required on the part of a place of database tractions ingen i consider the MRP records showinfiel wicht structure. Partise wie The role de vicepart. Partinis made from Transactions during a Period To illustrate action processings, we use a simple example for one part. Figure 6.1 MRP record for part 1250 paced over the weekend preceding week 1. The planer for part 1234 would be this MRP record on Monday of weck The planet fint action would be to try to launch the planned order for 50 units in pe nied that is the Mystem would first check availability of the raw materiale foed purt und then lanean order to the shop to make 50, if soticiend raw material is palable Launching would require allocating the secry w materials to the shop order, ing the frontheamed onderwerow for purt 1934, and creating a scheduled receipt for 50 a week, why he needed. Thereafter, a pick ticket would be the was and work could be Les during work I the following changes occurred, and the tractions were proceed - Actual abuso deck for 1234 dawk I were only 20 do the pled 30 The scheduled receipt for 50 de la week I was received on Tuesday, but 10 units were The inty w cda Thunday and ideal pieces were found The me pas week was changed a week Making of pics for wmples in werk The Mandereceding wok 2 is presies The part CMRP eerd is coming The ception as wallpa of 95 und 91, pesurse linearby cute short has been den. For example, in the planned andere Cwould sal be ming for the plader we af de date for to part 3 weken of der for 100 C 150 151 where FIGURE CU MAP m. The with wery person who www rigoslly card ready the med Becord the theater would be in periodotheleed - aatha urt med mer cause they will the aditional se po MA ed shortage la period 6 The week in afford Whelay in shortage in die wine per deres forming the med ports are stay MC will suff The long and some wnload les pece epok Wel intly cattle MONIAL censing Metal The power than the part of an MRP per can occur because of ples dhe involving many different parts. They may dont live the prindere being given they the MLP planet Principles Concluding Chapter provides an independendo describes based lee MINAR, Malapalayam material placer of Procedural Inadequacies MRP og tivities to cuential potem e MC www.weile des tivities are not wwe in stunt record. Some of the procedemed to proces y may be Teil de colors, les return to the cumple in Fire ped the separe for 95, there will be goftheder for 1 week air what would hapati 4 pieces were reped on the and will be up lepenie k sliting so pred while de discul de person in the cond, the only one werk would be Mohd , mock en person or dhe per she made her pus de perto tiem The Red Pilaad aai * Plant the master duction scheduling vendor plants The detail of Figure 6.1. For time-plused time-phased set of In addition to inputs. A bill of also important FIGURE 6.1 Manufacturing Planning and Control System This chapter deals with material requirements planning (MRP), a basic tool for perto in Patch production processes MRP managerial objective is to provide the right their assembly finished items. MRP is used by many companies that have to sing the detailed material planning function in the manufacture of componente Amplishing these plans without excess inventory, overtime, labor, or other te the right time to meet the schedules for completed products. To do this, MRP pois Arm plans for a part number, whether raw material, component, or finished Material ment planning in manufacturing planning and control: Where Chapter 6 is organized around the following five topics: MRP fit in the overall MPC system framework, and how is it related to other Record processing: What is the basic MRP record, and how is it produced? Technical issues. What additional technical details and supporting systems should you Using the MRP system. Who uses the system, how is it used, and how is the exa between MRP records and physical reality maintained? System dinamics: How does MRP reflect changing conditions, and why must tranka tions be processed properly? modules? . Route fil recognize? . Deule ple Requirements Planning in Manufacturing and Control For companies assembling end items from components produced in batch manufacturing processes , MRP is central to the development of detailed plans for part needs. It is often where companies start in developing their MPC systems. Facility with time-phased ple ning and the associated time-phased records in inents of the MPC system. Finally, although the introduction of IT und intents a la facturing proces have brought about fundamental changes in detailed material planning for some firma, companies continue to adapt the MRP approach chance their exiding systems For firmssing MRP, the frenal MPC framework depicted in Figure 61 shows that detailed requirement planning is characterized by the use of time-phaned (period by period) requirement records Several other apporting activities we shown in the from end, engine, and back end of the syviem as well. The front end of the MPC system producers the master production schedule (MS). The back end, crystem, deals with pro duction scheduling and control of the factory and with managing materials coming from vendor plants The detailed material planning factions in the portion of Figure 6.1. For firma preparing detailed anal plane ing Metaling time phased set of master production schedule mit and producing at time-phased set of component parts and raw material requirements In addition to master production schedule inputs, MRP requires two other basie inputs. A bill of material shows for each partner, what other part numbers are FIGURE 6.1 Manufacturing asing and Castrol System with trial requitements planning (MRP), a basic tool for perform ar planning function in the manufacture of component parts and sedm. MRP is used by many companies that have invested MRP managerial objective is to provide the right part me the chodules for completed products. To do this, MRP provides htumber, whether raw material, component, or finished pool bese plans without excess inventory, overtime, labor, or other resources and the following fise topics rent planning in manufacturing planning and control: Where does MC we framework, and how is it related to other MMC What is the basic MRP record, and how is it produced Wantechnical details and supporting systems should you We wis the system, how is it used, and how is the end - Fect changing conditions, and why must trans vond plytical reality maintained? ments Planning in Manufacturing atrol content produced in batchman del MPC Systems Facility with time.pada of desailed plans for partners 14, parts a and b Complete all cells highlighted in yellow in the assignment 3 spreadsheet found in Assignments in Blackboard Expected length: 1 page Expected time to complete: 60-90 minutes Deadline: Due by 11:59 pm MST on Sunday of Week 2 Submission method: Blackboard Assignments (Dropbox) as a completed spreadsheet (include your name in the file name) Value: 20% of final grade How to complete: 1. Read ABC Manufacturing Company (pp. 160-161) in the textbook 2. Answer question 14, parts a and b. (Please note: there is a typo in the textbook on page 160. Question 14.b.3 refers to Product B when it should refer to Product Y). 3. Copy the spreadsheet, complete the cells highlighted in yellow, answer the question at the end of the sheet and submit via Dropbox. 161 Why 1. Usip 14 TMC ABC Coily for the VEI. MES fondu Ye Master Production Schedule 1 2 3 We Number 4 5 6 Product 10 25 5 10 Product 5 30 20 20 Part Time Che witni ured u meniliste unit of ethered product dependentity of 40 medad wedd try Slance for competish ber stated pet under helled ceipt for 40 unit due to be del ting - Complete med for empormal deur at the beginning of the Schedule 250 1 Week 3 4 2 5 6 Gourmet ded Pred le balance Mandarder What they Only sy way planned anden for the 15 al the startowed Mende 30/ towe wrapped on the orde 2. Are cate of compet od of war med mera the school ,kaning le de hemmet Compiute Prosedur pets wmp *** Week 2 3 6 7 ded Merder 125 MC yum. 11 Chapter -6 sy Material Requirements Planning disi drag powe od po Coco dhed ghettory There are of H 6.1. for firms Is de FIGURE 6.1 Masalature Planning and Car System w the dated serial planning faction in the manufacture of compone per This is with material pagincertentie planine MRP buic tool for perform hot pretio promenagerial objective is to provide the right perta the meat the stabiles for completed products. To do this, MORP Molde for alle for chartet, her row meal.componenter finished put Accomplexes inventory overtime, labor, or other do important Chapter the following five opier Marilliginine planning and Where does MRP f the Mystem track, and how is it related to the MIC module Records What is the balie MRP record and bow is it produced Te Whitechnical details and supporting system told you MP Who we the system, how is it used, and how is the na Pundyycal reality maintained? How does MRP effect changing contitions, and whey muuttum the bedry renanted Material Requirements Planning in Manufacturing Planning and Control camping de produced in hac , Mistral to the development of detailed plans for partneri where it is in the others, Pacility with time- pede godt med disse to understanding many other as 18 127 FIGURE 6-2 The MATRA 1 2 5 10 10 16 por cumple for a car, I could show five For each wel the hill of materials could be a were car, nuwe are on the ende loputto MRP in inventorystu. Takowe and existings, and how many The Melo completo The need out to the detailed city plan del Deady stive prices where the umrlo by For cumpe, planning for a car wall det be which in denen purements for tires, and so on. B go beder the planning for wheel if the company w Nowa 15 wheels on and only needs 35 mon we ready been ordered, aly 15 more must be made A MPV role in material planning and control the balance Leade one pend Lot 50 The do te pida el plan de production into the detailed individual stepaneey to accom le ponides information for developing capacity plans, and it links to the Record Processing In this we were the MRP procedures starting with the base Murcin and construction. We then to an example ist ing planning component parts and end items. We mamine pochote cardine and the relationship that must be accounted for. We en look W MRP moord w reflect all the repaired relationships. We intend to show download MR moord can be managed independently while the gate pe fint period. The initial off bere periode is the man wed the bar planning hoon is wide. The power The med unique periode periodo di me mense dispod 1. 10 in pol pieder region of 12 Theod tool for specie di procedat Idy taken in adapted will be attende the term is mal during all chined by the line very or by moving the to satisfy the pour Acco with me wallet the begin be so made that my poder in which the gromne The scheduled modelos full Gehe This ownloaded Schoaded from pre and when we expect the des ay made ordering The Basic MRP Record Albert of the Miss universal seposentation of the status and plafon na te peber, veter x material, component part of finished patte e die 6.3 days the following information These few of us demand for the item during each period (ie. Bunge for the main at the beging of each period scheduled The procedimentary as for the the of each pened povjected wallste balance Mand replenishmet verders for the item is die beginning of each periode real 4 is presently the scheduled for a period I will wat Sche The buske MRP recond the provides the common per needed for complex probat reader anderen the bill of material de la entry and wheband mation, and ind time offering Wear Te day. 8pc bave been made to a vender. The ordigheded receipts is also at the beginning of the period, tha ided the period during with them will be available The row for 2 "Preted available balance. The timing consis monda beard and Juirements have been satisfied for this theed of the period, that is row is the projected balance aer replenish The Troyected me balance tow has an extra time backet show the gewThe quantity shown in period is the projected The how the balance at the went time that is, in Figure 62.thebe chord L. The procedallable balance shown at the end of a period se sont is the best and acceding periods. For pich the projected available balance at the end of period i an adding the scheduled to be received to the beginning balance of 4 The roof 10 la period 2 reduces the projected balance to a uw bara very specific Units of the item might be on hand pocaithe As Example lofMaterial Fine 3 shows and more. The complete with membiding for its del from the phone, open copacometenda. The epidemins, created by haning the welded handed with woodland was the welded top hentais rudy willing the top lande coupling in the top handle bracket la siyo with the steel Made inget FIGURE 6.3 The 1605 San Sharel Show with Cempat Parts and Asemblies Tube 19 Tip w ho het nilable to meet prot requirements because they are already promised or allocate for her purpose Themed andet des" w is determined directly from the "Projected wallable Malane row. Whenever the projected available bulance shows a quantity insufficient atsly pro nequirements a negative quantity), additional material must be planned for This is done by creating a poder release in time to keep the projected available bal. ance from becoming seative: For example, in Figure 6.2, the projected available balance at the end of period 44 units. This is not sufficient to meet the gross requirement of 10 is period 5. Because the lead time is one weck, the MRP system creates a plamed order the beginning of week 4 providing a lead time offset of one week. As we have used lote of Suits, the projected available balance at the end of week 5 is 44 unit Another way that this lopie is explained is to note that the balance for the end of period 4 sanity is the beginning inventory for period 5. during which there's a gross requireme of Ounits. The diffemme between the wallable inventory of 4 and the gross requirement el 10 is a not requirement of 6 units in period 5. Thus, an order for at least 6 units must be planned for period 4 lowolda shortage in period 5. The MRP system produces the planned crder release data in response to the groot quirement, scheduled receipt and projected available dita. When a planned order la created for the most immediate a current period, it is in the action bucket. A quantity in the than lucht metna rete action is needed now to avoid a future problem. The action is The planeers shown in the scheduled receipt now because they by herdaction of purchasing No material has been commined to dicture. The planned oder is nous to sentry on a Christmas list, since the partma has been made. Like Christmas ist w ist. Aschede in order mailed to a catalog firm for mandarden planned anders as much as to change the scheduled receipt. No converting planned to scheduled receipts any earlier than necessary las man 1605 16 the one which wascheduled receipt T T 13 131 Encuene More thenber of subassemblin, word ingly more places. This puble only the product structure dans BON 64. Both provided BOM dead ago Now the hing pate 012 dhe past two ma 11 how Indeed Bo Beheer 137. Newlands (12 de coupling un padel y seeded to pro wade the day at how beet wa Miten Below in the motore actor of The BOMM data chito di BOMshawl RCURE 64 Sud per problem pas afa the way he pod en doen. Also, if we he Groot Net Explosion Explosion is de produto 019 compeded to stay with me mumber will puthammadyace As explosion takes place on the comparte day ory scheduled receipts de la tierrants are linked through the went. Although the pendantur make a determination of not mean tim. To re the shovel ciampie Suppose the company top 100 bove, and we were reposible for making the 13122plasm We presentary and scheduled to ceipt Information for which the ground fordon ponent of the top landies be clear, in Pipe 6.5 437 FIGURE 6.5 Grand Net Reims Calculations for a som Share Part Part Sched Gron Description Number Recepti Regulaments Tophandle assembly 23 100 Top handle 22 3 082 11495 22 28 he required) det my Tupande bracket Tophande coupling 1118 39 133 RGURE 66 phandle coupling (1118 de a thing Bed cheddon 100 from 75 tagad, Cutie there is for 150. The 25 ans of the more of handles, brackets and which Me Locking on down, weet the het is for 4 Thia for the boding. Since there are op die ou for the requirement for part 1 MRP not only provides the thao frodestatis, the demande for dependenta for top unde este We depende demand on be exactly calculated. It send the coupling (1) bear In the cutting approacia froatchedulele cha kecen Ou testerandependent demandien, ruch as the street The pendent demand often called the Bundestal principle of MRPUS udposted on the im Tender now shows will have to left y require alculations Leal Time tapos www many of each bombily and compare part dowded shed product antity. What it does not do, however, who bella meded. Referring back to Pin 64 the planendel and handle coupling send to be welded the See the woods and sched. These ships are known as precedent They now the ander is shich things must be do It is recedenti, dening when to schedule achet parte de los produce parthat the ladies the plane (129) como se to the couple bested in one day while the top handle coupling Belediye ale to make and Depende dieren ime, any systems for men cump, film has pro locales con brachial of 100 chains weet Wat te dwa part (with propriate multiple are started at the same time de las ertestod for chart showing how this cutting apprzech will be pl provides a back 11495, 13122, 1605 de Black scheduling him it will pone the commitment of dawno apital campoomil Irimation wych. They DOM doo all compete onda tenging ponents and see The ing pad is complaint le in the pipeline MALP shinaatulatatatatti pertine Fedewhat being peach, which starts all parts prong times are on the car Wada 12 de andered the end of day, all the wilt work for emple, the place of MRP TAS EGRE 6.8 MB CURE 6 Chat 11 . 6 . unde 23 3 is 10 ad 00 . 19 al UN Late1 L50 020 RI ta 14 4 50 10 11495 Brac 1 3 1510 bilo 10 ao 1 129 Top Mande + 1510 endimet Linking the MRP Records Predstof individual time-phased MRP records for the handle heid Webare already well fint five periods of the 2 mil record dows crecord in Figure 6. To see how that record fit into the whole we Weid 100w shovels were going to be dead edhe ng That is, the roulements row in the MRP meord for manter 1333 6.3 teeled of 100 time phases 20 in week 2. 10 m 20,wed 1.33 10 in welk 10. Because cachowa the Grow more"row for the top handle shows met of Statwaleted before in the grows to net calculations of Figures obepin. Note the val planed anders for the top handie musembly is the The line handie bly in two weeks, calculated as the fire des per in Polphabe days for paperwork. The lend time for andre er mere end at least one sede e dos ef paperwork time as added to Pannede 16 1118 Top bandie ung de stock - 30 Sched 20 20 and for those dan in her 63. The schede these day week. The current bibend ung the week loading and recoge mathildebee the coeperent. The developed dyr der levde Technical Issues Dowk 2 boca by the Nethe hace 3 derive from this used di Thu the best The theophandel ently dore latine. The ordering po Gre, Acepto one in 19. In the of the the wadi penetrarents with the there is any the pludonders and the ut the top andle coupling for this pur, denk The order age will chedule a planet halance from ping below the safety sched Fordplade opling this bool of the planned we have yet to clearly show is the back scheduling effect. We for periods the 20-cility Mock wild we de tu delay the start of the top handle becket (pur 123 sa de Mulher of the four planned order for part 129 fint until week two weeks where is planned anden for per 1118. Both of these planned anden some of 35 derived from the planned order for the bracket Cher that the orders are back scheduled. This relationship can be mite emple, because the planned order release timing dependa yoksyinels well as the ind time. The MRP system, however, to efth information and determines the appropriate planned andere beds back whaling All e Mly the linking of the MRP time-phased records The "Plased for the toplande sembly (13122) becomes with the prop melletter tow for each of its component parts 457,082. 1120Land they are linked to the Once all the gross requirements data are available for a particular round, the individual record processing topic is applied and the planned order mener det des gross requirements to its components, fong de produc (BOMO level-by-level basis. In some cases, parts will recent there that one source one parts), wat is true for the nails and met woede er requirements will reflect needs from more the planned andere Aker system accounts for this and incorporis The Mamen nike proper account of prosenting. They also incorporate houd soliding und die feit desired for turing procedures, afety codes und pertama memporal, lower, is independence of the partner Wake penge beves need not expliciter her when I done the MRP record for the snow shovels will rema water enters that the system will cretly pas dewels grans requiremena do system Processing Frequency That way to the Madhow linked as recived, the MP code a bebe proche ! recordement viewer decide the more would be promote Processing all of the modern. This that all part sumber mondatoto processed. When som Then starting with the end, damchisa very large procesing demand when he na stively complet we. To wond this common problema pead ground jobs. In additing in de school take place atically during flowych weekende The problems with cering lestry is that the pa and neede expressed in the model. This decrease in concha bodi uticipated the led scheduled receipts are received a message other characta Asunted serp, tequirement can make occur, they can dilte meghaty the transaction. Changes in conded to create and onder release become rose quando home transactions may mga pandai reflected in the time has come per More frequent processing of the MRP de Income fewer plures When the minded prime actions will be indicated to come for behan. A logical respecte al poco tigured amount of all by proceso de reconsided by dan Ans tive to repeat the change. With the afected by the new arched The arpent for the not change mal daily or comme progress of the word of the opport The MRP stem accomplishes daractered for very curate computer records and to pred Seen dan de an occasional regeneration to de pened order is my be frustrated with these front ng my walcow of commended to OF DEVOL The ma The cost canapetost change in its hypersensitivity, Bucketless Systems To win the proofgarted to theme of time buckets. When the back cat mall the problems are reduced significantly. However, smaller back , which can and computation cost. Aber MRP is the case and doe dates for each requirement, scheduled raadpandandet. The reports are printed out on whatever his Bucket MRP area bener way to the computer. Above and beyond that As many firmsplay alithaal Safety Stock and Safety Lead Time Carrying out tuled compond plass tillid by closing teada and safety lead me in the MRP od. Salony w a butterflod above and asing any mode for the top de company faluty lead time is procedure where shop orders or purch den www.healed to menor periode before the Safety stocks can be exposed. There projected wailable under pero. To incorpone y almohad (planned to be received a roapewolde s necesary Figure how to be one-week safety lealtime Notice led led dates are changed. Sulety lind meist Both safety and all time we can be ously. However, borbeid that aintadrilanadiantara they need to be received, in fact, the way and safety lead mes effectively, med et Scenes y are not well understood worden aus te laten werken will try to get our Abone of you wality od whitput will be required to meet corner Safety stock tends to be din MRP na siste probleme where some milf mappen usage is a frequente de los de others who the major incity is the timing her to form af buys from a vender homines delivery ty lead me prinde belle than safety stock iding by dates the sprach allows beter maintenance of lead time of iets and provides more precise med in the preach is consistent with state-of-the-art software, many firms now we bedenisystem. The major addition is that the planning cycle her is balles. That i, planeeridas necessary, not on a periodie schedule, and the cells botened Lot Sizing Is the ovenample of Figure 6.8. we see a fixed lot size (50 units for the nails and the sole procedure. The lotine of 50 for the nails could have been someone tale of podle of the result of calculation. The time-phased information can be used in combined with other du to develop lot sizes conforming to organizational od We might ach the conclusion, for the top handle (1118) in Figure 6., that desirable to set up the equipment for 4 parts in week 2, und again for 10 parts in werk we'd combine the readers. The time plased record permits us to develop such disrufe Het slot wil only way the net requirements for one or more periodi Several fortal procedures have been developed for lot sizing the time phased requires aperte el curying inventory longer. In many cases, discrete lot sizes possible with Mo more poing as fuel et niees. Compare the residual inventory or malls a weckt 4 5 6 7 FIGURE 6.9 MRP Record with Salty Lead The 1 2 Part 129 Grosi requirements Top handle 1 15 18 with of this Figure 6., for ople bracket ead time 1 Lottorit Scheduled cepts Projected As finance the foot locha sabo sple-minded since it doo der yheder physical factors. However, hatching planned or Sebed nem level of the bill of materials cascades de level will increase the next level in the product dhe bill of material. This is expecially the ed. This can be good to some extent for compondant When this is the case again lot siring may he appropriate riy 15 15 15 12 10 Sety lead time1 balance Planned order releases 141 Low-Level Coding wert 04, we see that the rivet (part 14127) The Ponderow for complex where will be used dot as posset sont at there we arquirements for the rivets (14127) frede On the top and record for this con part before the record pred te wary here powing de wet. Become mes to the new Con for penge the form planeerders Testing y amigo femeile che mitter The press they were he problem for penders, the to meet special mediabetes pendant of the indend BOM. By convention, the top final assembly els he pre requirements and he accumulated, the computations must be redone metod a level. In our comple, the snow where would have a low.level code oro Figuere te dy are pret the low-level code numberThe next level down part sumber 45 013, 11495, 216,013 and 14127) we low-level coded 2. Note the common partne) just hem ooded as nel 2, indicating it in used lower in the product structure. The higher tulee end, the lower in the product structure the purt is used. Consequently, the lake led eipe part indicates the lowest level of age and is the level code sed for that put Wenchermple when part numbers 129 and 1118 are codul level 3. The level code wiped to any part number is based on the parts unope in all prod. red by the option One low-level des e established, MRP record processing proceeds from one level ce the starting at level code. This ensure all grou requirements have bem puses puter its MRP record is processed. The result is planning of com paper ordinated with the needs of all higher level purt number. Within a level, the Mga typically done in partumbet sequence. Pegging al ter oprettes for a part to all the planned onder de demand tu tad te requirements. The persing records contain the on the depased record. For lower level part de migle corti e specific ter onders to be satisdied by de pegel planned orders of Sigheroveltum powden the part is sold as a service part Service Parts Service par demand met de ti not to be understand. The worpus added directly into the po tepe view, the rice party and the source of illos The low-level code for swell porn part as well as de och at As actual service partner poids will These can be partially buffered with locally and in vicepartme) or by the Molly records, expected shapecondi bestified to wear Condominium perhaps be met with lots is needed to butentifs Pagudpupugh the MRP records from a lub de la sent the reverse of the redure, unbers of all in on which the part compared to wher-ered date. Where used in www whered file. Peting shoes te pociis gross requirements in each time period Thomaerial problem all the way up the Planning Horizon In Figure 6 de fotode for period 4 grow our in mponding room This proces falha 1149) Firm Planned Orders The concord for an india ped for berber Theref donderdagve take place in the last The set for his This is a les and his (put idle andere cathered more on ein wedd Scheduled Receipts versus Planned Order Releases 3. Ayew updates would be reaching A medending of MRP require knowledge of certainly differences between chamada planned and we dech ofference before the ent, whereas the planned onder is only a platefois de to ung the late Ascheduled receipt for purchased purchase and which is a forma comitent, has been prepared. Sumiy herritards there an open shop order. Roma ale anaposebe specifically committed to that order to longer for the des. One major rent of this distinction, which bei Figure is the planned andere explode grossequirements for componen stocks 4. Reconoci od 5. Tindley precis 6. Uning In the mods for the precong This be bewMP nestly 1. Indicateurs, depende plane's job I had the open oder den Ada ben the fooing question: Where would a scheduled recept the up hede (13122) in Figure 6.8 of my 20 units in week he reflected Food for the comporte (457,082 and 114957? The answer is nowhere Schedule weet lected in the current feed for component parts. For that scheduled receiptist, the component parts would have already been assigned to the shop onder penting the scheduled foodipe for part 13122 and removed from the available of the comments. As for MRP is concerned, the 20 part 457.40 part 02, und 20 per 118 The other way to becoming 20 part 13122s. The 13122 di proces, the comparecords Order Long Onder die process of www orders. This procen la promesses in the time period, the action hodet. Onder de sched led recreeting them in Odegisting of the und purchase orden doing these deshen hedelme stockroom Actu time, he was tory and eliminate the scheduled Poola pening have to be carefully defined to all are property pro The order indicated by MRP alfonso darts and safety stocks willing. We wird lo-for-lot proaches and faedo Aleppo with wareness of the implications of the leas Forn, alles be aasaiyyanaparilalar taletaintamil afety Macky he is the action bodist When an order is sched, try to includes flar omp and other proces. The typical come per for yield ones that was the order boven quired to effect poodcouveronden, hindadeg, the shown on the shop onder die het beroestyle cur during production Using the MRP System littiin, wedi critical aspects of using the MRP system to ensure that MRP ested with physical flows of material The MRP Planner The part det inobed with the MRP sen outputs are planner. The typically on the plane pinventory control, sed purchasing departments. The es love the permally for making detailed decisions that let the material mories trong terpent. The age of discrimin is carefully linked to us, without higher edhe ratim, ey med den plus de end items delined for customers. Their action Coop MRP chance of third of partumbo murod portid election par West Coatia Allocation and daily Checking Acmapdeal attaintarad larly in leaching that only check for the cury wr wow boven wat wie 30 31 pened the check of part 02.30 of 11.10) MRP 1 1. Recorders and when den Ma Pattadatay 201 oddelby the cor, in me The act of corpo pertanto the partido be the new the dhe lyer, with differences gecede at have been red, but whose componen Ate walay ng tickets are typically and digitale for a specified to probe y action the shop order to be delivered to parti 1. Aty of een where la med paalPrimps.o become the pain mil samayal checking ette e sheh promet Wieland lace is reduced accordingly, Arany continue physical rock picking are type of anderen hoop The may hally on hand should much what por este plaats allocated. If they don't much corrective The di un facilitates inventory counting and other procedure form gn Bottom-up Replanning Bulamin Exception Codes Explore Montesparate the vital few from the trai of the control and the Mystem is functioning Com ning pay 10 20 percent of the partners will req posetion codes are in two nel corries. The in helpos, includes checks for des bound the planning hot than check valid part numbers, the decided forway. The second part of exception codes directly supporte MILF, Incided on the following is of exception (action) Wednesday of the Thief ping this site the only of the 10 bed the 2 made from this, hed The polysis of the 10 de without ting i per mowe should work with the work This should be done if we were the data is the change because the 10 bovenwold fylkes