Answered step by step

Verified Expert Solution

Question

1 Approved Answer

please help me solve the last step Data table Activity Materials handling Machine setup.... Insertion of parts Finishing Allocation Base Activity Cost Allocation Rate Number

please help me solve the last step

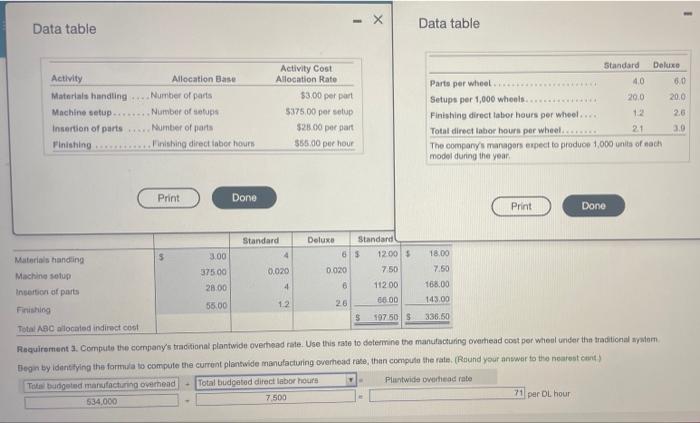

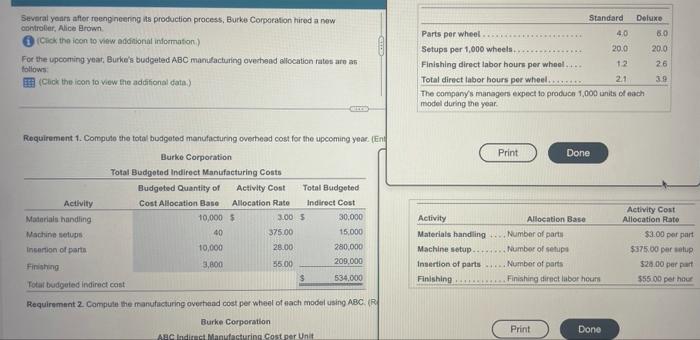

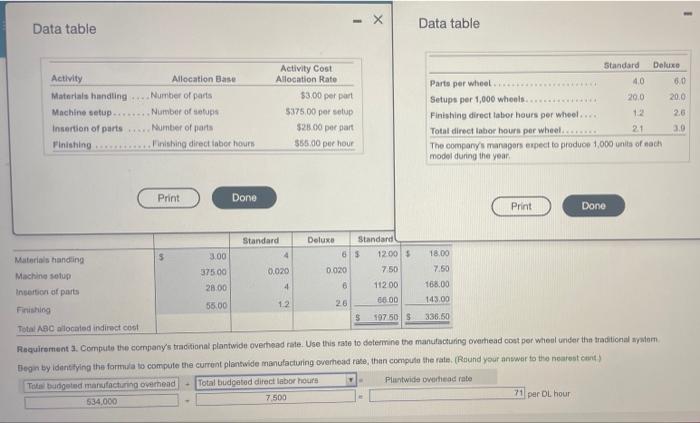

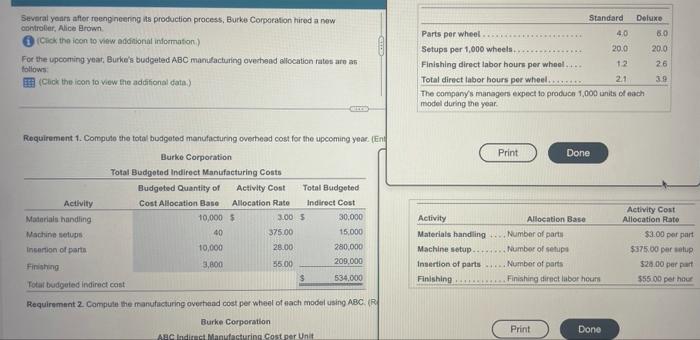

Data table Activity Materials handling Machine setup.... Insertion of parts Finishing Allocation Base Activity Cost Allocation Rate Number of parts Number of setups Number of parts Finishing direct labor hours Print Done Standard $3.00 per part $375.00 per setup $28.00 per part $55.00 per hour Deluxe X Parts per wheel. 4.0 Setups per 1,000 wheels... 20.0 1.2 Finishing direct labor hours per wheel.... Total direct labor hours per wheel..... 21 The company's managers expect to produce 1,000 units of each model during the year. Print Done Materials handling 3.00 12:00 $ 18.00 375.00 0.020 0.020 7:50 7.50 Machine setup 28.00 6 112.00 168.00 Insertion of parts 66.00 143.00 55.00 12 26 Finishing $ 197.50 S 336.50 Total ABC allocated indirect cost Requirement 3. Compute the company's traditional plantwide overhead rate. Use this rate to determine the manufacturing overhead cost per wheel under the traditional system Begin by identifying the formula to compute the current plantwide manufacturing overhead rate, then compute the rate. (Round your answer to the nearest cent) Plantwide overhead rate Total budgeted manufacturing overhead Total budgeted direct labor hours 71 per DL hour 7,500 534,000 Standard 65 Data table Standard Deluxe 6.0 20.0 2.6 3.9 Several years after reengineering its production process, Burke Corporation hired a new controller, Alice Brown (Click the icon to view additional information.) For the upcoming year, Burke's budgeted ABC manufacturing overhead allocation rates are as follows: (Click the icon to view the additional data) Requirement 1. Compute the total budgeted manufacturing overhead cost for the upcoming year. (Ent Burke Corporation Total Budgeted Indirect Manufacturing Costs Budgeted Quantity of Activity Cost Total Budgeted Indirect Cost Activity Cost Allocation Base Allocation Rate Materials handling 10,000 $ 30,000 15,000 Machine setups 40 375.00 Insertion of parts 10,000 28.00 280,000 209,000 Finishing 3,800 55.00 534,000 Total budgeted indirect cost Requirement 2. Compute the manufacturing overhead cost per wheel of each model using ABC. (R Burke Corporation ABC Indirect Manufacturing Cost per Unit 3.00 $ Deluxe 6.0 40 Parts per wheel. 20.0 Setups per 1,000 wheels.. 20.0 1.2 26 Finishing direct labor hours per wheel.... Total direct labor hours per wheel... 2.1 3.9 The company's managers expect to produce 1,000 units of each model during the year. Print Done Activity Allocation Base Number of parts Materials handling Machine setup. Number of setups Insertion of parts Number of parts Finishing Finishing direct labor hours Print Done Standard Activity Cost Allocation Rate $3.00 per part $375.00 per setup $28.00 per part $55.00 per hour

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started