Answered step by step

Verified Expert Solution

Question

1 Approved Answer

please help me with this question. [40 points] The warehouse manager on a construction site is trying to figure out a rational way to control

please help me with this question.

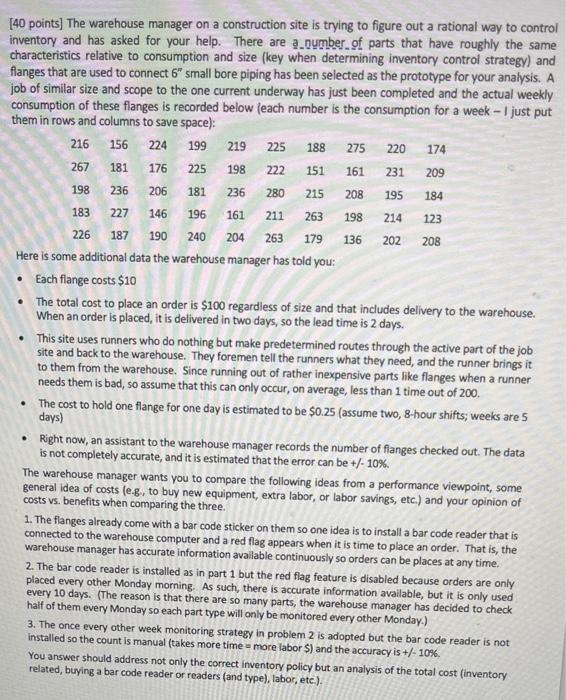

[40 points] The warehouse manager on a construction site is trying to figure out a rational way to control inventory and has asked for your help. There are a number of parts that have roughly the same characteristics relative to consumption and size (key when determining inventory control strategy) and flanges that are used to connect 6" small bore piping has been selected as the prototype for your analysis. A job of similar size and scope to the one current underway has just been completed and the actual weekly consumption of these flanges is recorded below (each number is the consumption for a week - I just put them in rows and columns to save space): 216 156 224 199 219 225 188 275 220 174 267 176 225 151 161 209 206 181 236 208 184 181 198 222 231 198 236 280 215 195 183 227 146 196 161 211 263 198 214 123 226 208 . 187 190 240 204 263 179 136 202 Here is some additional data the warehouse manager has told you: Each flange costs $10 The total cost to place an order is $100 regardless of size and that includes delivery to the warehouse. When an order is placed, it is delivered in two days, so the lead time is 2 days. This site uses runners who do nothing but make predetermined routes through the active part of the job site and back to the warehouse. They foremen tell the runners what they need, and the runner brings it to them from the warehouse. Since running out of rather inexpensive parts like flanges when a runner needs them is bad, so assume that this can only occur, on average, less than 1 time out of 200 The cost to hold one flange for one day is estimated to be $0.25 (assume two, 8-hour shifts; weeks are 5 days) Right now, an assistant to the warehouse manager records the number of flanges checked out. The data is not completely accurate, and it is estimated that the error can be +/- 10%. The warehouse manager wants you to compare the following ideas from a performance viewpoint, some general idea of costs (eg, to buy new equipment, extra labor, or labor savings, etc.) and your opinion of costs vs. benefits when comparing the three. 1. The flanges already come with a bar code sticker on them so one idea is to install a bar code reader that is connected to the warehouse computer and a red flag appears when it is time to place an order. That is, the warehouse manager has accurate information available continuously so orders can be places at any time. 2. The bar code reader is installed as in part 1 but the red flag feature is disabled because orders are only placed every other Monday morning. As such, there is accurate information available, but it is only used every 10 days. (The reason is that there are so many parts, the warehouse manager has decided to check half of them every Monday so each part type will only be monitored every other Monday.) 3. The once every other week monitoring strategy in problem 2 is adopted but the bar code reader is not installed so the count is manual (takes more time = more labor $) and the accuracy is +/- 10%. You answer should address not only the correct inventory policy but an analysis of the total cost inventory related, buying a bar code reader or readers (and type), labor, etc.). [40 points] The warehouse manager on a construction site is trying to figure out a rational way to control inventory and has asked for your help. There are a number of parts that have roughly the same characteristics relative to consumption and size (key when determining inventory control strategy) and flanges that are used to connect 6" small bore piping has been selected as the prototype for your analysis. A job of similar size and scope to the one current underway has just been completed and the actual weekly consumption of these flanges is recorded below (each number is the consumption for a week - I just put them in rows and columns to save space): 216 156 224 199 219 225 188 275 220 174 267 176 225 151 161 209 206 181 236 208 184 181 198 222 231 198 236 280 215 195 183 227 146 196 161 211 263 198 214 123 226 208 . 187 190 240 204 263 179 136 202 Here is some additional data the warehouse manager has told you: Each flange costs $10 The total cost to place an order is $100 regardless of size and that includes delivery to the warehouse. When an order is placed, it is delivered in two days, so the lead time is 2 days. This site uses runners who do nothing but make predetermined routes through the active part of the job site and back to the warehouse. They foremen tell the runners what they need, and the runner brings it to them from the warehouse. Since running out of rather inexpensive parts like flanges when a runner needs them is bad, so assume that this can only occur, on average, less than 1 time out of 200 The cost to hold one flange for one day is estimated to be $0.25 (assume two, 8-hour shifts; weeks are 5 days) Right now, an assistant to the warehouse manager records the number of flanges checked out. The data is not completely accurate, and it is estimated that the error can be +/- 10%. The warehouse manager wants you to compare the following ideas from a performance viewpoint, some general idea of costs (eg, to buy new equipment, extra labor, or labor savings, etc.) and your opinion of costs vs. benefits when comparing the three. 1. The flanges already come with a bar code sticker on them so one idea is to install a bar code reader that is connected to the warehouse computer and a red flag appears when it is time to place an order. That is, the warehouse manager has accurate information available continuously so orders can be places at any time. 2. The bar code reader is installed as in part 1 but the red flag feature is disabled because orders are only placed every other Monday morning. As such, there is accurate information available, but it is only used every 10 days. (The reason is that there are so many parts, the warehouse manager has decided to check half of them every Monday so each part type will only be monitored every other Monday.) 3. The once every other week monitoring strategy in problem 2 is adopted but the bar code reader is not installed so the count is manual (takes more time = more labor $) and the accuracy is +/- 10%. You answer should address not only the correct inventory policy but an analysis of the total cost inventory related, buying a bar code reader or readers (and type), labor, etc.)

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started