Answered step by step

Verified Expert Solution

Question

1 Approved Answer

please help me with this question This is all the information I was given for the question that I sent you. I have nothing else

please help me with this question

This is all the information I was given for the question that I sent you. I have nothing else to add to it. I'm going to check with my professor to make sure if the question is written correctly.

In the meantime, I want to replace this question with another question hopefully you can help me with this one.

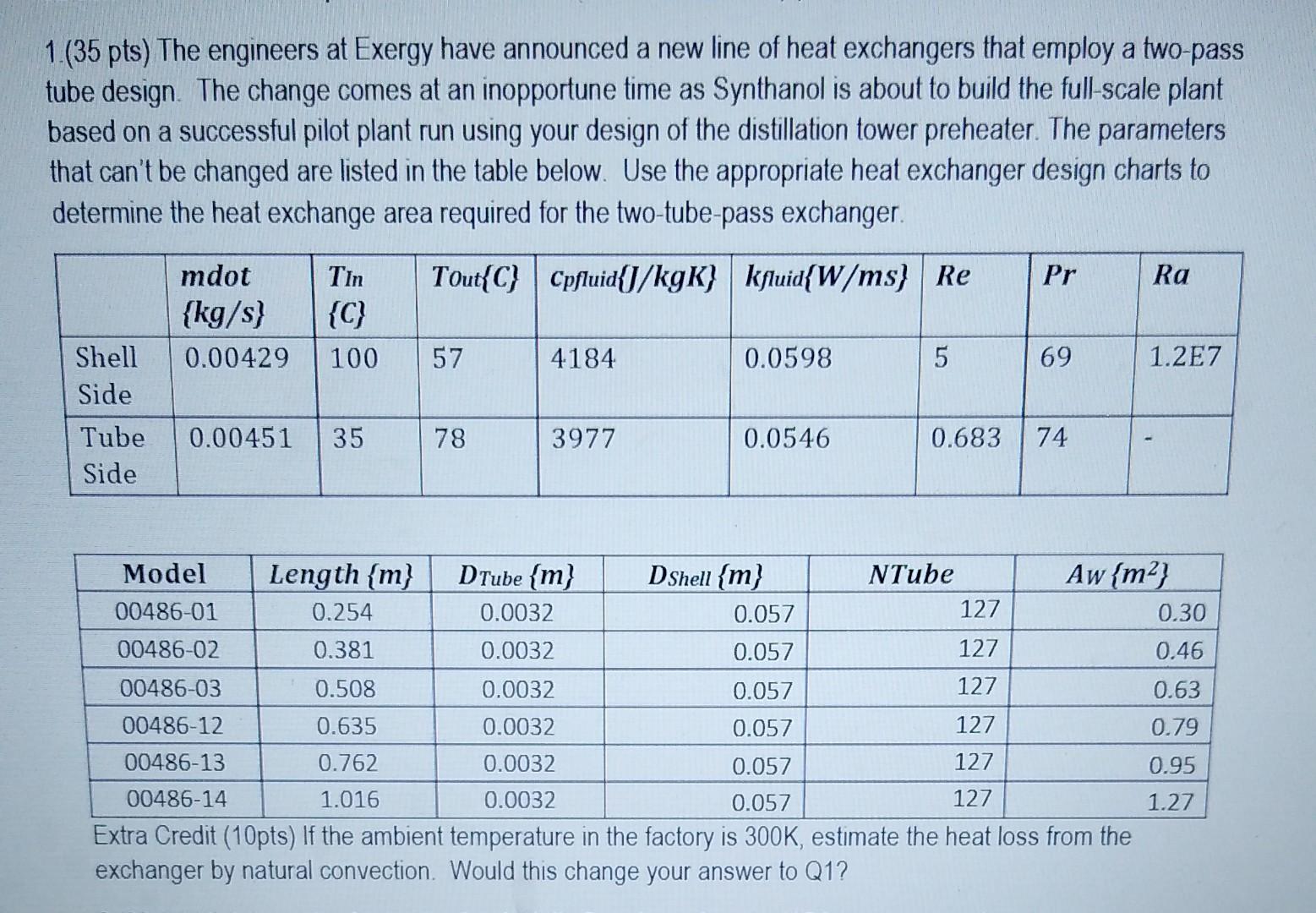

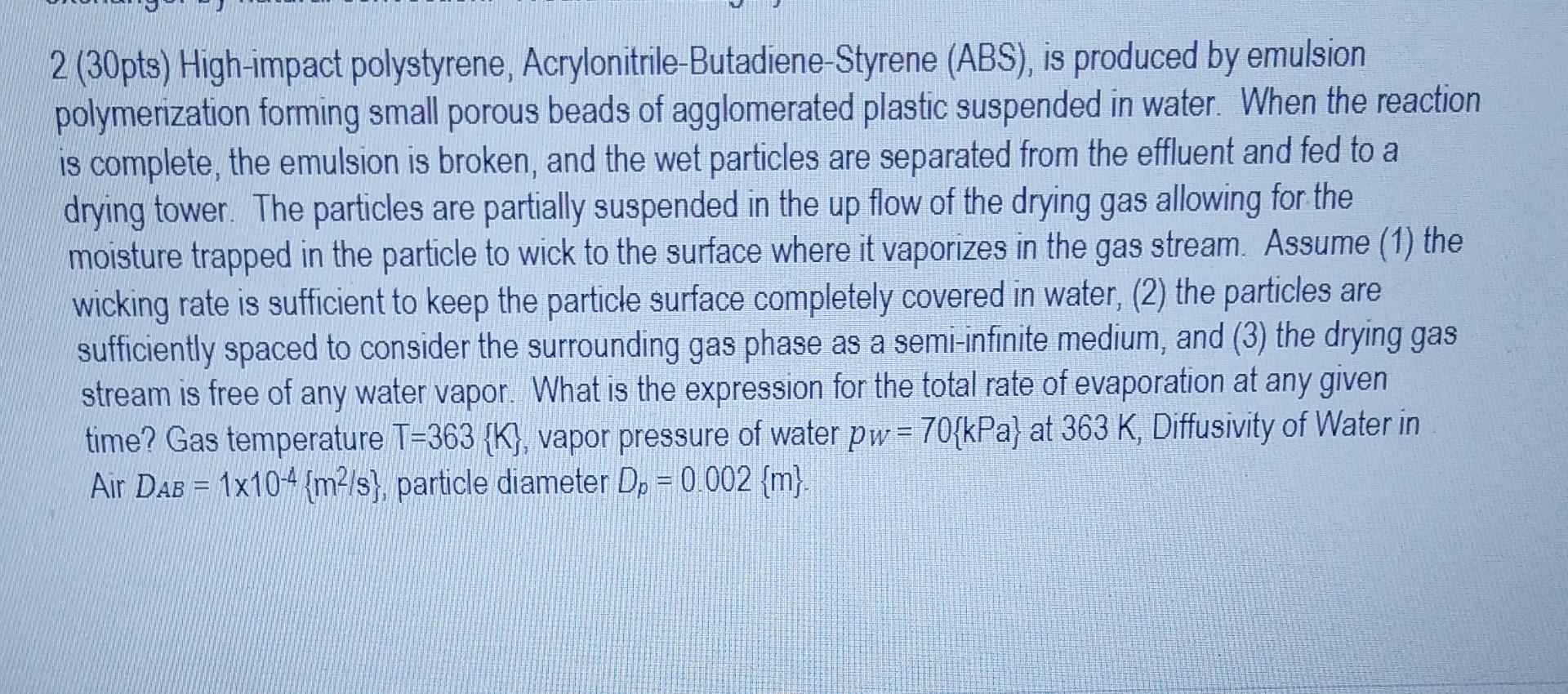

1. (35 pts) The engineers at Exergy have announced a new line of heat exchangers that employ a two pass tube design. The change comes at an inopportune time as Synthanol is about to build the full-scale plant based on a successful pilot plant run using your design of the distillation tower preheater. The parameters that can't be changed are listed in the table below. Use the appropriate heat exchanger design charts to determine the heat exchange area required for the two-tube-pass exchanger. Tout{C) Cpfluid(J/kgK) kfluid{W/ms) Re Pr Ra mdot {kg/s) 0.00429 Tin {C} 100 57 4184 0.0598 5 69 1.27 Shell Side 0.00451 35 78 3977 0.0546 0.683 74 Tube Side Model Length {m} DTube {m} DShell {m} NTube Aw {m} 00486-01 0.254 0.0032 0.057 127 0.30 00486-02 0.381 0.0032 0.057 127 0.46 00486-03 0.508 0.0032 0.057 127 0.63 00486-12 0.635 0.0032 0.057 127 0.79 00486-13 0.762 0.0032 0.057 127 0.95 00486-14 1.016 0.0032 0.057 127 1.27 Extra Credit (10pts) If the ambient temperature in the factory is 300K, estimate the heat loss from the exchanger by natural convection. Would this change your answer to Q1? 2 (30pts) High-impact polystyrene, Acrylonitrile-Butadiene-Styrene (ABS), is produced by emulsion polymerization forming small porous beads of agglomerated plastic suspended in water. When the reaction is complete, the emulsion is broken, and the wet particles are separated from the effluent and fed to a drying tower. The particles are partially suspended in the up flow of the drying gas allowing for the moisture trapped in the particle to wick to the surface where it vaporizes in the gas stream. Assume (1) the wicking rate is sufficient to keep the particle surface completely covered in water, (2) the particles are sufficiently spaced to consider the surrounding gas phase as a semi-infinite medium, and (3) the drying gas stream is free of any water vapor. What is the expression for the total rate of evaporation at any given time? Gas temperature T=363 {K}, vapor pressure of water pw = 70{kPa) at 363 K, Diffusivity of Water in Air DAB = 1x10-4 {m2/s), particle diameter Dp = 0.002 {m} 1. (35 pts) The engineers at Exergy have announced a new line of heat exchangers that employ a two pass tube design. The change comes at an inopportune time as Synthanol is about to build the full-scale plant based on a successful pilot plant run using your design of the distillation tower preheater. The parameters that can't be changed are listed in the table below. Use the appropriate heat exchanger design charts to determine the heat exchange area required for the two-tube-pass exchanger. Tout{C) Cpfluid(J/kgK) kfluid{W/ms) Re Pr Ra mdot {kg/s) 0.00429 Tin {C} 100 57 4184 0.0598 5 69 1.27 Shell Side 0.00451 35 78 3977 0.0546 0.683 74 Tube Side Model Length {m} DTube {m} DShell {m} NTube Aw {m} 00486-01 0.254 0.0032 0.057 127 0.30 00486-02 0.381 0.0032 0.057 127 0.46 00486-03 0.508 0.0032 0.057 127 0.63 00486-12 0.635 0.0032 0.057 127 0.79 00486-13 0.762 0.0032 0.057 127 0.95 00486-14 1.016 0.0032 0.057 127 1.27 Extra Credit (10pts) If the ambient temperature in the factory is 300K, estimate the heat loss from the exchanger by natural convection. Would this change your answer to Q1? 2 (30pts) High-impact polystyrene, Acrylonitrile-Butadiene-Styrene (ABS), is produced by emulsion polymerization forming small porous beads of agglomerated plastic suspended in water. When the reaction is complete, the emulsion is broken, and the wet particles are separated from the effluent and fed to a drying tower. The particles are partially suspended in the up flow of the drying gas allowing for the moisture trapped in the particle to wick to the surface where it vaporizes in the gas stream. Assume (1) the wicking rate is sufficient to keep the particle surface completely covered in water, (2) the particles are sufficiently spaced to consider the surrounding gas phase as a semi-infinite medium, and (3) the drying gas stream is free of any water vapor. What is the expression for the total rate of evaporation at any given time? Gas temperature T=363 {K}, vapor pressure of water pw = 70{kPa) at 363 K, Diffusivity of Water in Air DAB = 1x10-4 {m2/s), particle diameter Dp = 0.002 {m}

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started