Answered step by step

Verified Expert Solution

Question

1 Approved Answer

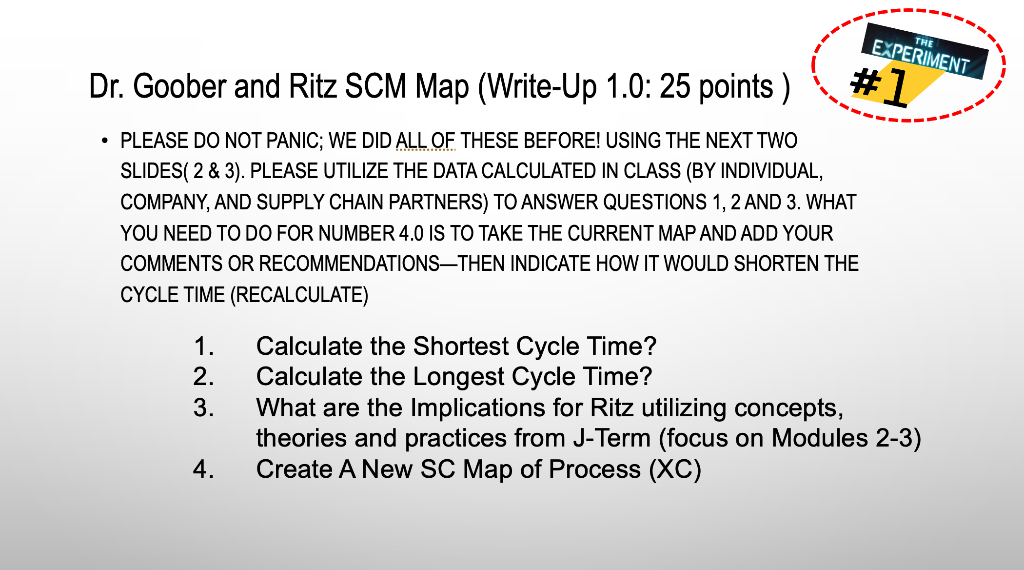

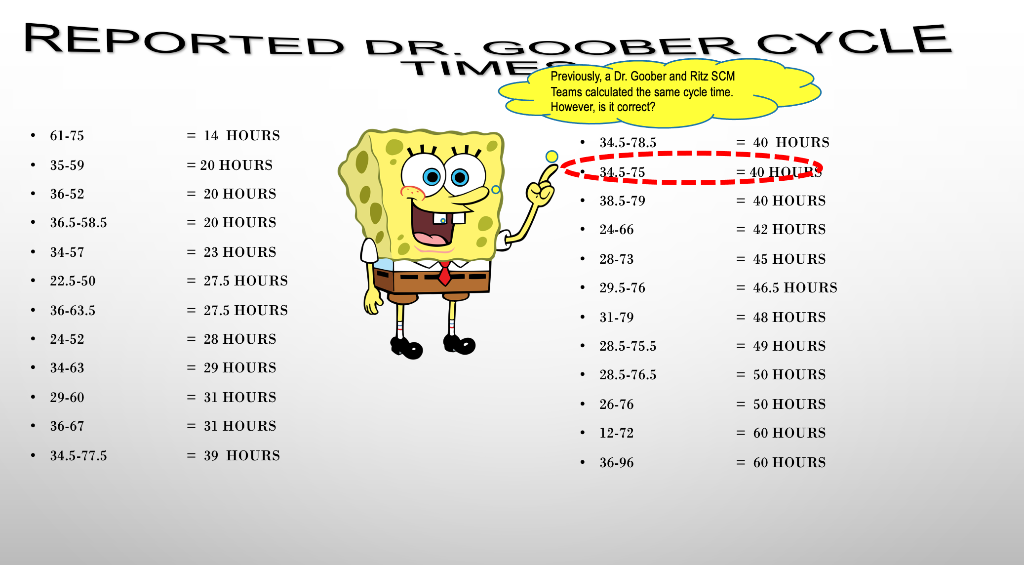

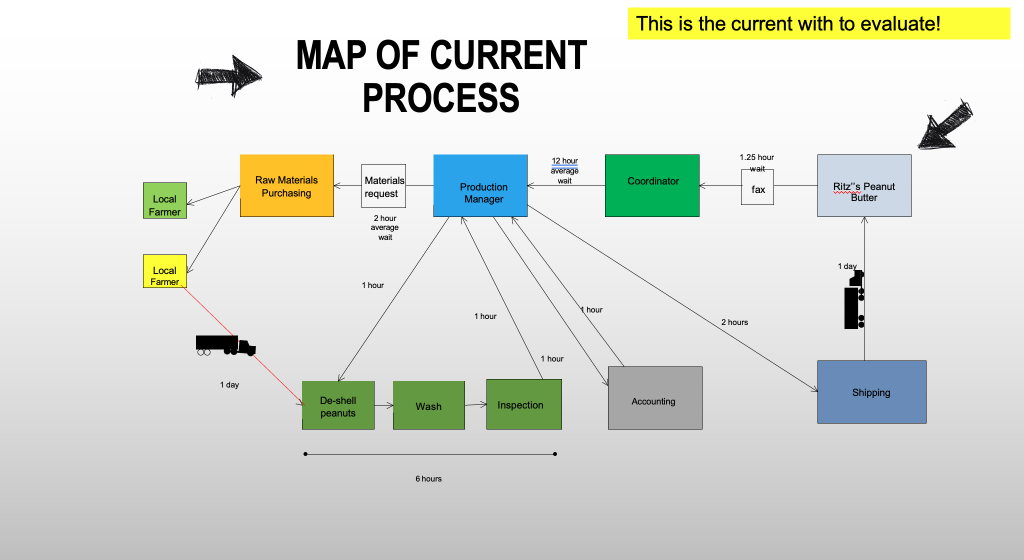

Please Refer to Diagram one to answer questions 1-3 and Diagram two to answer question 4. THE EXPERIMENT Dr. Goober and Ritz SCM Map (Write-Up

Please Refer to Diagram one to answer questions 1-3 and Diagram two to answer question 4.

THE EXPERIMENT Dr. Goober and Ritz SCM Map (Write-Up 1.0:25 points ) #l PLEASE DO NOT PANIC; WE DID ALL OF THESE BEFORE! USING THE NEXT TWO SLIDES( 2 & 3). PLEASE UTILIZE THE DATA CALCULATED IN CLASS (BY INDIVIDUAL, COMPANY, AND SUPPLY CHAIN PARTNERS) TO ANSWER QUESTIONS 1, 2 AND 3. WHAT YOU NEED TO DO FOR NUMBER 4.0 IS TO TAKE THE CURRENT MAP AND ADD YOUR COMMENTS OR RECOMMENDATIONSTHEN INDICATE HOW IT WOULD SHORTEN THE CYCLE TIME (RECALCULATE) 1. 2. 3. Calculate the shortest Cycle Time? Calculate the Longest Cycle Time? What are the Implications for Ritz utilizing concepts, theories and practices from J-Term (focus on Modules 2-3) Create A New SC Map of Process (XC) 4. REPORTED DR. GOOBER CYCLE TIME Previously, a Dr. Goober and Ritz SCM Teams calculated the same cycle time. However, is it correct? . 61-75 = 14 TOURS 34.5-78.5 = 40 HOURS . 35-59 = 20 HOURS 34.5-75 10 HOURS 36-52 = 20 HOURS . 38.5-79 = 40 HOURS . 36.5-58.5 = 20 HOURS 24-66 = 42 HOURS . 34-57 = 23 HOURS 28-73 = 45 HOURS 22.5-50 = 27.5 HOURS 29.5-76 = 46.5 HOURS 36-63.5 = 27.5 HOURS . 31-79 = 48 HOURS 24-52 = 28 HOURS 28.5-75.5 = 49 HOURS . 34-63 = 29 HOURS 28.5-76.5 = 50 HOURS . 29-60 = 31 HOURS 26-76 = 50 HOURS 36-67 = 31 HOURS . 12-72 = 60 HOURS 34.5-77.5 = 39 HOURS . 36-96 = 60 HOURS This is the current with to evaluate! MAP OF CURRENT PROCESS 1.25 hour 12 hour average wait Raw Materials Purchasing Materials request Coordinator Production Manager fax Ritz's Peanut Butter Local Farmer 2 hour average wait 1 day Local Farmer 1 hour hour 1 hour 2 hours 1 hour 1 day De-shell Shipping Wash Inspection Accounting peanuts 6 hours THE EXPERIMENT Dr. Goober and Ritz SCM Map (Write-Up 1.0:25 points ) #l PLEASE DO NOT PANIC; WE DID ALL OF THESE BEFORE! USING THE NEXT TWO SLIDES( 2 & 3). PLEASE UTILIZE THE DATA CALCULATED IN CLASS (BY INDIVIDUAL, COMPANY, AND SUPPLY CHAIN PARTNERS) TO ANSWER QUESTIONS 1, 2 AND 3. WHAT YOU NEED TO DO FOR NUMBER 4.0 IS TO TAKE THE CURRENT MAP AND ADD YOUR COMMENTS OR RECOMMENDATIONSTHEN INDICATE HOW IT WOULD SHORTEN THE CYCLE TIME (RECALCULATE) 1. 2. 3. Calculate the shortest Cycle Time? Calculate the Longest Cycle Time? What are the Implications for Ritz utilizing concepts, theories and practices from J-Term (focus on Modules 2-3) Create A New SC Map of Process (XC) 4. REPORTED DR. GOOBER CYCLE TIME Previously, a Dr. Goober and Ritz SCM Teams calculated the same cycle time. However, is it correct? . 61-75 = 14 TOURS 34.5-78.5 = 40 HOURS . 35-59 = 20 HOURS 34.5-75 10 HOURS 36-52 = 20 HOURS . 38.5-79 = 40 HOURS . 36.5-58.5 = 20 HOURS 24-66 = 42 HOURS . 34-57 = 23 HOURS 28-73 = 45 HOURS 22.5-50 = 27.5 HOURS 29.5-76 = 46.5 HOURS 36-63.5 = 27.5 HOURS . 31-79 = 48 HOURS 24-52 = 28 HOURS 28.5-75.5 = 49 HOURS . 34-63 = 29 HOURS 28.5-76.5 = 50 HOURS . 29-60 = 31 HOURS 26-76 = 50 HOURS 36-67 = 31 HOURS . 12-72 = 60 HOURS 34.5-77.5 = 39 HOURS . 36-96 = 60 HOURS This is the current with to evaluate! MAP OF CURRENT PROCESS 1.25 hour 12 hour average wait Raw Materials Purchasing Materials request Coordinator Production Manager fax Ritz's Peanut Butter Local Farmer 2 hour average wait 1 day Local Farmer 1 hour hour 1 hour 2 hours 1 hour 1 day De-shell Shipping Wash Inspection Accounting peanuts 6 hoursStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started