Answered step by step

Verified Expert Solution

Question

1 Approved Answer

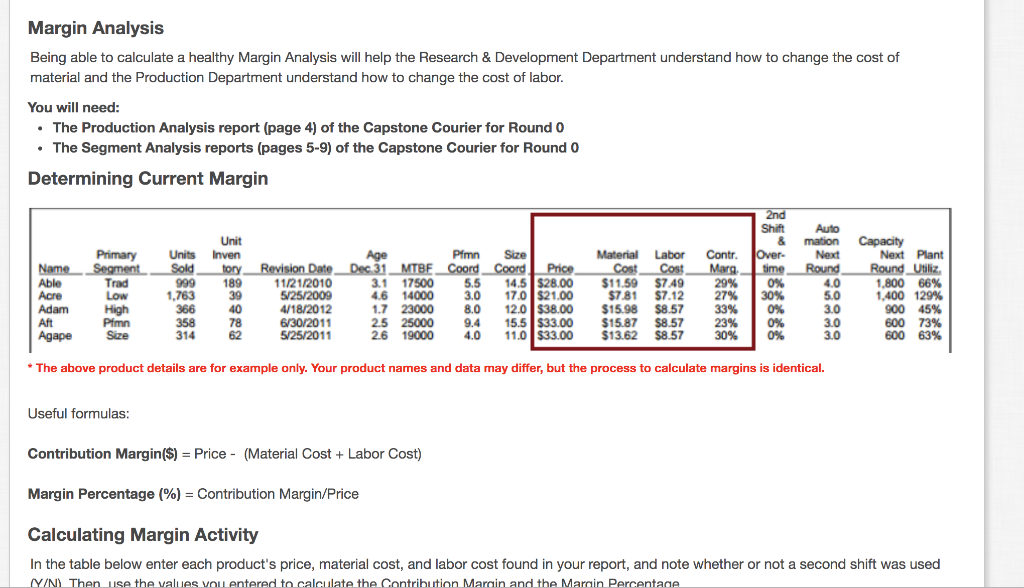

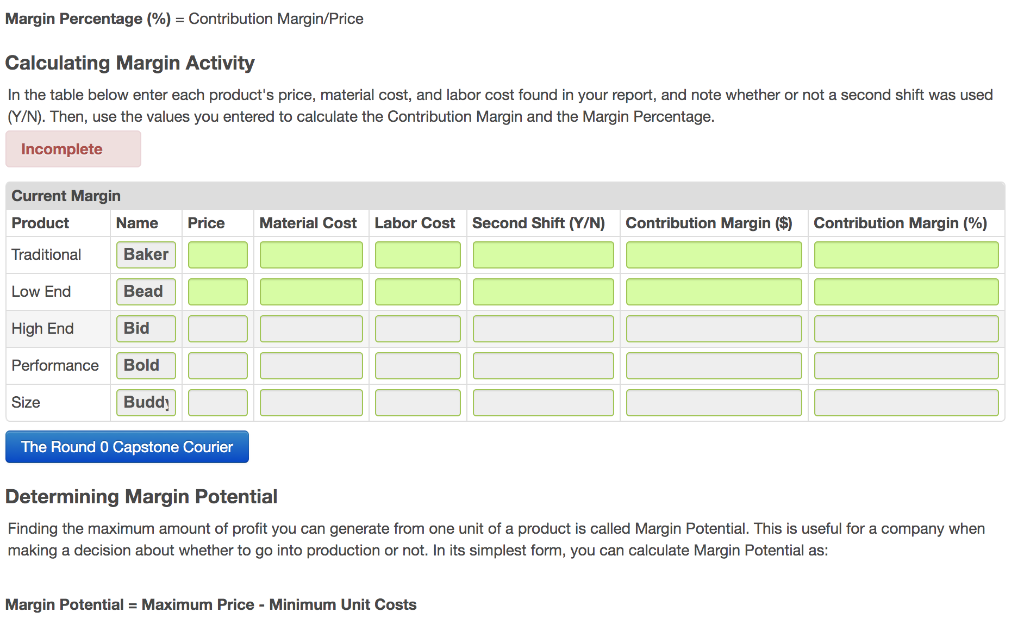

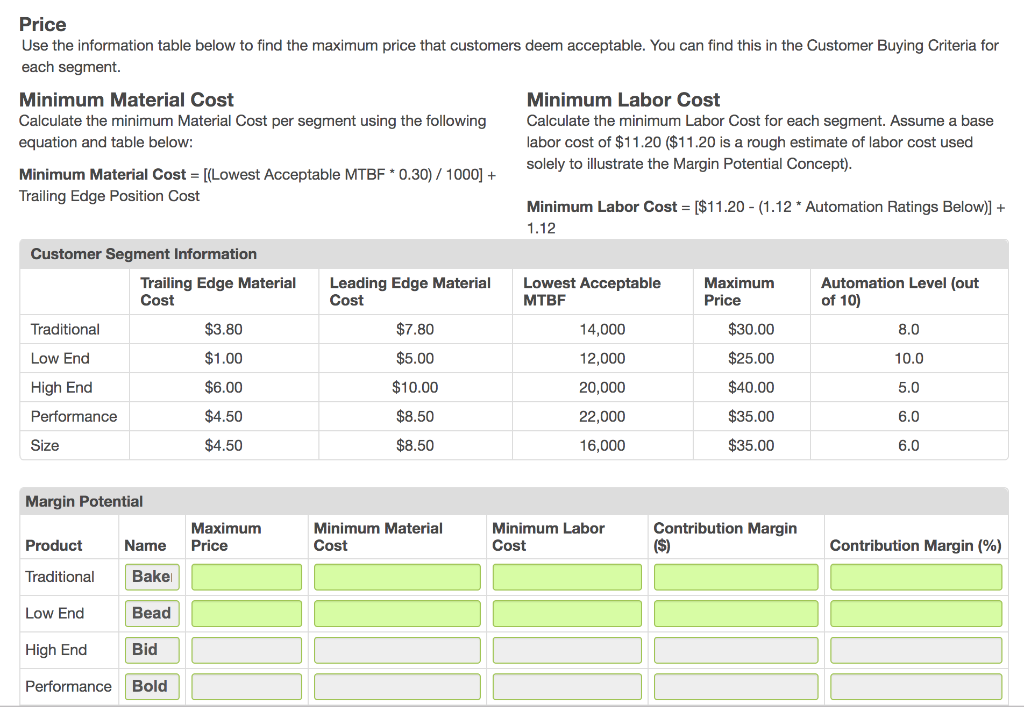

Please solve both tables!! Margin Analysis Being able to calculate a healthy Margin Analysis will help the Research & Development Department understand how to change

Please solve both tables!!

Margin Analysis Being able to calculate a healthy Margin Analysis will help the Research & Development Department understand how to change the cost of material and the Production Department understand how to change the cost of labor. You will need: The Production Analysis report (page 4) of the Capstone Courier for Round O The Segment Analysis reports (pages 5-9) of the Capstone Courier for Round 0 Determining Current Margin 2nd Shift Auto mation Next Round Over- time Name Able Acre Adam 40 Primary Segment Trad Low High Pfmn Size Units Sold 999 1.763 366 Unit Inven Age tory_Revision Date_Dec 31 MTBF 189 11/21/2010 3.1 17500 5/25/2009 4.6 14000 4/18/2012 1.7 23000 6/30/2011 2.5 25000 5/25/2011 26 19000 Pfmn Size Coord_CoordPrice 5.5 14.5 $28.00 $21.00 120 $38.00 $33.00 $33.00 Material Cost $11.59 $7.81 $15.98 $15.87 $13.62 170 Labor Cost $7.49 $7.12 $8.57 $8.57 $8.57 Capacity Next Plant Round Utiliz 1,800 66% 1,400 129% 900 45% 600 73% 600 63% Contr. Marg 29% 27% 33% 23% 30% 5.0 3.0 Aft 15.5 Agape * The above product details are for example only. Your product names and data may differ, but the process to calculate margins is identical. Useful formulas: Contribution Margin($) = Price - (Material Cost + Labor Cost) Margin Percentage (%) = Contribution Margin/Price Calculating Margin Activity In the table below enter each product's price, material cost, and labor cost found in your report, and note whether or not a second shift was used (Y/N) Then use the values vou entered to calculate the Contribution Marain and the Marain Percentage Margin Percentage (%) = Contribution Margin/Price Calculating Margin Activity In the table below enter each product's price, material cost, and labor cost found in your report, and note whether or not a second shift was used (Y/N). Then, use the values you entered to calculate the Contribution Margin and the Margin Percentage. Incomplete Current Margin Product Name Price Material Cost Labor Cost Second Shift (Y/N) Contribution Margin ($) Contribution Margin (%) Traditional Baker Low End Bead High End Bid Performance Bold Size Buddy The Round 0 Capstone Courier Determining Margin Potential Finding the maximum amount of profit you can generate from one unit of a product is called Margin Potential. This is useful for a company when making a decision about whether to go into production or not. In its simplest form, you can calculate Margin Potential as: Margin Potential = Maximum Price - Minimum Unit Costs Price Use the information table below to find the maximum price that customers deem acceptable. You can find this in the Customer Buying Criteria for each segment. Minimum Material Cost Calculate the minimum Material Cost per segment using the following equation and table below: Minimum Labor Cost Calculate the minimum Labor Cost for each segment. Assume a base labor cost of $11.20 ($11.20 is a rough estimate of labor cost used solely to illustrate the Margin Potential Concept). Minimum Material Cost = [(Lowest Acceptable MTBF*0.30)/1000) + Trailing Edge Position Cost Minimum Labor Cost = ($11.20 - (1.12 * Automation Ratings Below)] + 1.12 Customer Segment Information Trailing Edge Material Cost Leading Edge Material Cost Lowest Acceptable MTBF Maximum Price Automation Level (out of 10) Traditional 14,000 $30.00 8.0 Low End 12,000 $25.00 10.0 $3.80 $1.00 $6.00 $4.50 $4.50 $7.80 $5.00 $10.00 $8.50 $8.50 High End Performance $40.00 5.0 20,000 22,000 $35.00 $35.00 6.0 6.0 Size 16,000 Margin Potential Maximum Price Contribution Margin Product Minimum Material Cost Minimum Labor Cost ($) Contribution Margin (%) Name Bakel Traditional Low End Bead High End Bid Performance Bold Margin Analysis Being able to calculate a healthy Margin Analysis will help the Research & Development Department understand how to change the cost of material and the Production Department understand how to change the cost of labor. You will need: The Production Analysis report (page 4) of the Capstone Courier for Round O The Segment Analysis reports (pages 5-9) of the Capstone Courier for Round 0 Determining Current Margin 2nd Shift Auto mation Next Round Over- time Name Able Acre Adam 40 Primary Segment Trad Low High Pfmn Size Units Sold 999 1.763 366 Unit Inven Age tory_Revision Date_Dec 31 MTBF 189 11/21/2010 3.1 17500 5/25/2009 4.6 14000 4/18/2012 1.7 23000 6/30/2011 2.5 25000 5/25/2011 26 19000 Pfmn Size Coord_CoordPrice 5.5 14.5 $28.00 $21.00 120 $38.00 $33.00 $33.00 Material Cost $11.59 $7.81 $15.98 $15.87 $13.62 170 Labor Cost $7.49 $7.12 $8.57 $8.57 $8.57 Capacity Next Plant Round Utiliz 1,800 66% 1,400 129% 900 45% 600 73% 600 63% Contr. Marg 29% 27% 33% 23% 30% 5.0 3.0 Aft 15.5 Agape * The above product details are for example only. Your product names and data may differ, but the process to calculate margins is identical. Useful formulas: Contribution Margin($) = Price - (Material Cost + Labor Cost) Margin Percentage (%) = Contribution Margin/Price Calculating Margin Activity In the table below enter each product's price, material cost, and labor cost found in your report, and note whether or not a second shift was used (Y/N) Then use the values vou entered to calculate the Contribution Marain and the Marain Percentage Margin Percentage (%) = Contribution Margin/Price Calculating Margin Activity In the table below enter each product's price, material cost, and labor cost found in your report, and note whether or not a second shift was used (Y/N). Then, use the values you entered to calculate the Contribution Margin and the Margin Percentage. Incomplete Current Margin Product Name Price Material Cost Labor Cost Second Shift (Y/N) Contribution Margin ($) Contribution Margin (%) Traditional Baker Low End Bead High End Bid Performance Bold Size Buddy The Round 0 Capstone Courier Determining Margin Potential Finding the maximum amount of profit you can generate from one unit of a product is called Margin Potential. This is useful for a company when making a decision about whether to go into production or not. In its simplest form, you can calculate Margin Potential as: Margin Potential = Maximum Price - Minimum Unit Costs Price Use the information table below to find the maximum price that customers deem acceptable. You can find this in the Customer Buying Criteria for each segment. Minimum Material Cost Calculate the minimum Material Cost per segment using the following equation and table below: Minimum Labor Cost Calculate the minimum Labor Cost for each segment. Assume a base labor cost of $11.20 ($11.20 is a rough estimate of labor cost used solely to illustrate the Margin Potential Concept). Minimum Material Cost = [(Lowest Acceptable MTBF*0.30)/1000) + Trailing Edge Position Cost Minimum Labor Cost = ($11.20 - (1.12 * Automation Ratings Below)] + 1.12 Customer Segment Information Trailing Edge Material Cost Leading Edge Material Cost Lowest Acceptable MTBF Maximum Price Automation Level (out of 10) Traditional 14,000 $30.00 8.0 Low End 12,000 $25.00 10.0 $3.80 $1.00 $6.00 $4.50 $4.50 $7.80 $5.00 $10.00 $8.50 $8.50 High End Performance $40.00 5.0 20,000 22,000 $35.00 $35.00 6.0 6.0 Size 16,000 Margin Potential Maximum Price Contribution Margin Product Minimum Material Cost Minimum Labor Cost ($) Contribution Margin (%) Name Bakel Traditional Low End Bead High End Bid Performance BoldStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started