please solve question 5-14

next i will attach the example

DO NOT solve the example.

only question 5-14

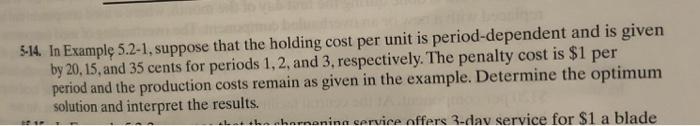

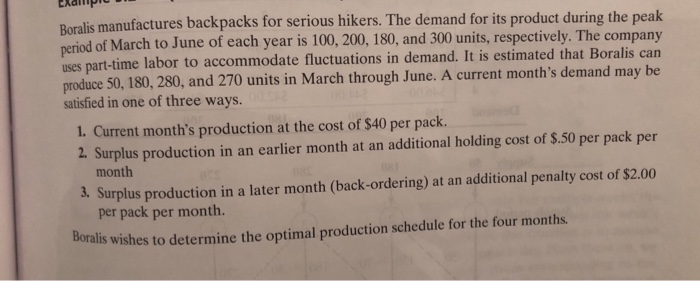

5-14. In Example 5.2-1, suppose that the holding cost per unit is period-dependent and is given by 20, 15, and 35 cents for periods 1, 2, and 3, respectively. The penalty cost is $1 per period and the production costs remain as given in the example. Determine the optimum solution and interpret the results. w w wnanina service offers 3.dan cantina for $1 ohled Boralis manufactures backpacks for serious hikers. The demand for its product during the peak period of March to June of each year is 100, 200, 180, and 300 units, respectively. The company uses part-time labor to accommodate fluctuations in demand. It is estimated that Boralis can produce 50, 180, 280, and 270 units in March through June. A current month's demand may be satisfied in one of three ways. 1. Current month's production at the cost of $40 per pack. 2. Surplus production in an earlier month at an additional holding cost of $.50 per pack per month 3. Surplus production in a later month (back-ordering) at an additional penalty cost of $2.00 per pack per month oralis wishes to determine the optimal production schedule for the four months. 5-14. In Example 5.2-1, suppose that the holding cost per unit is period-dependent and is given by 20, 15, and 35 cents for periods 1, 2, and 3, respectively. The penalty cost is $1 per period and the production costs remain as given in the example. Determine the optimum solution and interpret the results. w w wnanina service offers 3.dan cantina for $1 ohled Boralis manufactures backpacks for serious hikers. The demand for its product during the peak period of March to June of each year is 100, 200, 180, and 300 units, respectively. The company uses part-time labor to accommodate fluctuations in demand. It is estimated that Boralis can produce 50, 180, 280, and 270 units in March through June. A current month's demand may be satisfied in one of three ways. 1. Current month's production at the cost of $40 per pack. 2. Surplus production in an earlier month at an additional holding cost of $.50 per pack per month 3. Surplus production in a later month (back-ordering) at an additional penalty cost of $2.00 per pack per month oralis wishes to determine the optimal production schedule for the four months