Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Please use Aspen Plus Software 2.1 in the process of producing vinyl chloride from chlorine and ethylene, the stream from the outlet of high temperature

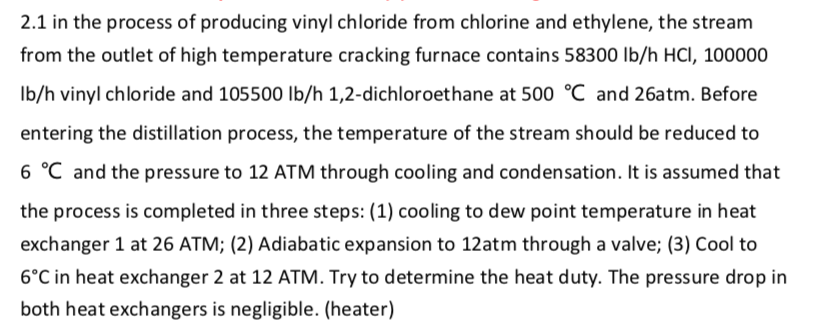

Please use Aspen Plus Software

2.1 in the process of producing vinyl chloride from chlorine and ethylene, the stream from the outlet of high temperature cracking furnace contains 58300 lb/h HCI, 100000 lb/h vinyl chloride and 105500 lb/h 1,2-dichloroethane at 500 C and 26atm. Before entering the distillation process, the temperature of the stream should be reduced to 6 C and the pressure to 12 ATM through cooling and condensation. It is assumed that the process is completed in three steps: (1) cooling to dew point temperature in heat exchanger 1 at 26 ATM; (2) Adiabatic expansion to 12atm through a valve; (3) Cool to 6C in heat exchanger 2 at 12 ATM. Try to determine the heat duty. The pressure drop in both heat exchangers is negligible. (heater) 2.1 in the process of producing vinyl chloride from chlorine and ethylene, the stream from the outlet of high temperature cracking furnace contains 58300 lb/h HCI, 100000 lb/h vinyl chloride and 105500 lb/h 1,2-dichloroethane at 500 C and 26atm. Before entering the distillation process, the temperature of the stream should be reduced to 6 C and the pressure to 12 ATM through cooling and condensation. It is assumed that the process is completed in three steps: (1) cooling to dew point temperature in heat exchanger 1 at 26 ATM; (2) Adiabatic expansion to 12atm through a valve; (3) Cool to 6C in heat exchanger 2 at 12 ATM. Try to determine the heat duty. The pressure drop in both heat exchangers is negligible. (heater)Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started