Answered step by step

Verified Expert Solution

Question

1 Approved Answer

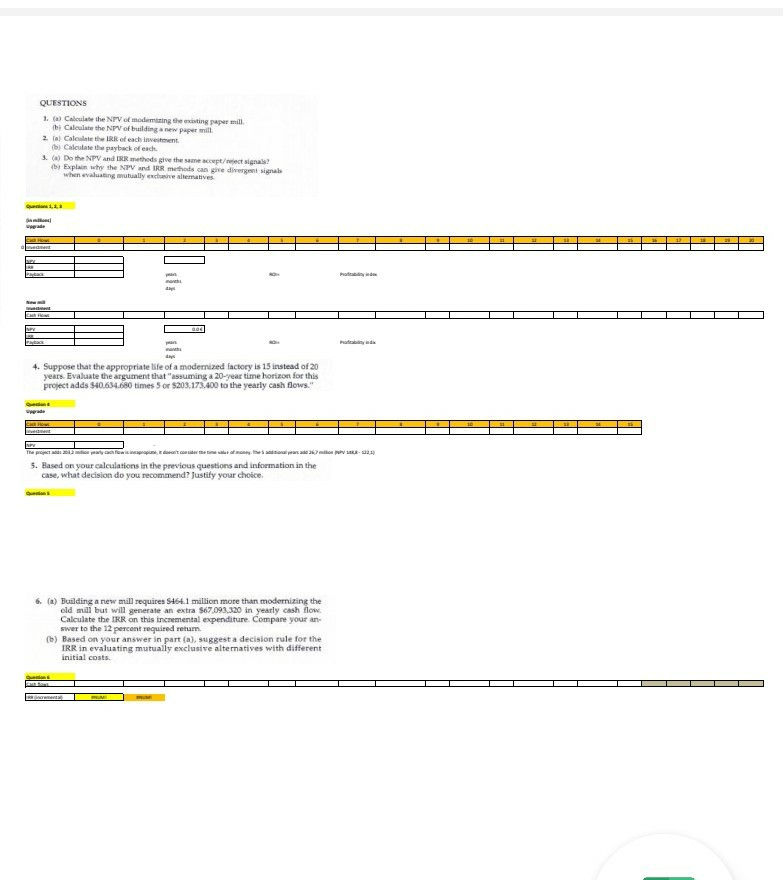

pls.help with this Capital Budgeting case. Case 20 Fort Greenwold I am asked to answer 6 questions and fill in the excel template (the last

pls.help with this Capital Budgeting case.

Case 20 Fort Greenwold

I am asked to answer 6 questions and fill in the excel template (the last picture above).Thank you

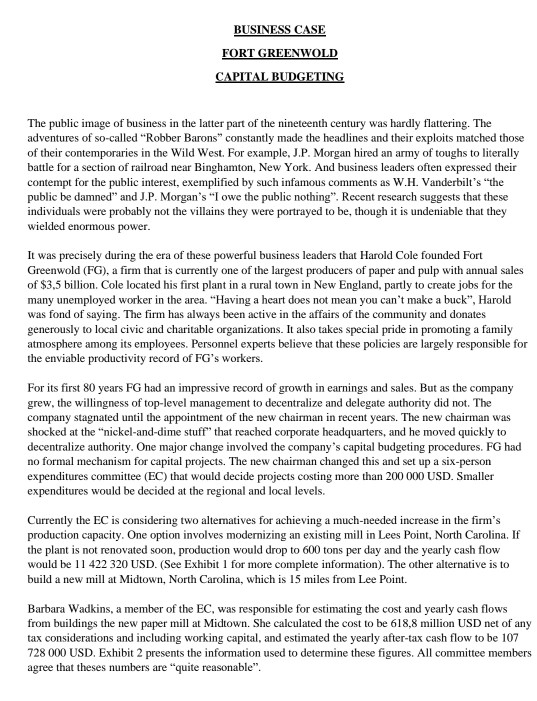

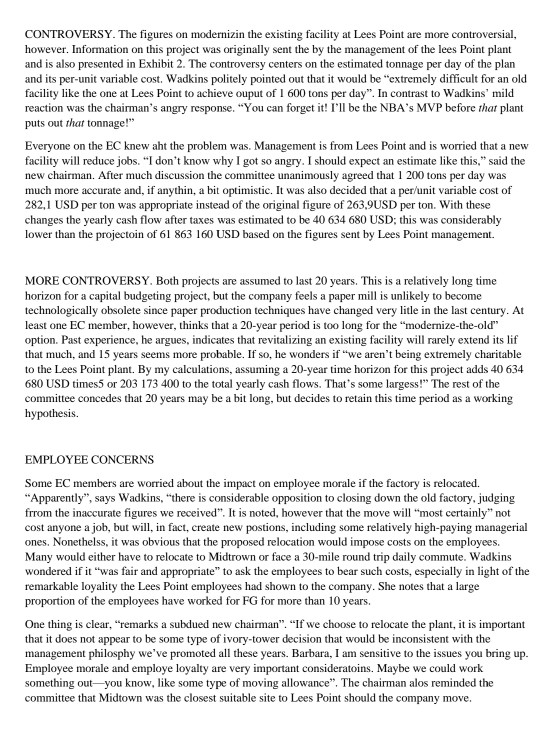

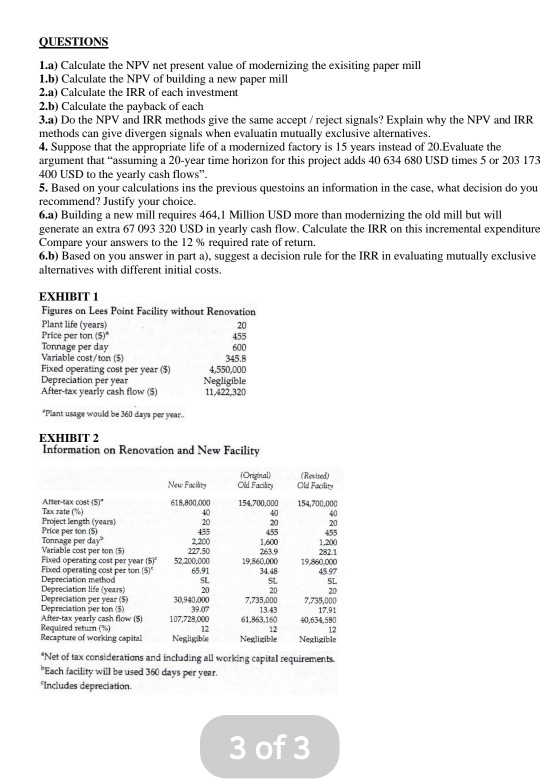

BUSINESS CASE FORT GREENWOLD CAPITAL BUDGETING The public image of business in the latter part of the nineteenth century was hardly flattering. The adventures of so-called "Robber Barons" constantly made the headlines and their exploits matched those of their contemporaries in the Wild West. For example, J.P. Morgan hired an army of toughs to literally battle for a section of railroad near Binghamton, New York. And business leaders often expressed their contempt for the public interest, exemplified by such infamous comments as W.H. Vanderbilt's the public be damned" and J.P. Morgan's "I owe the public nothing". Recent research suggests that these individuals were probably not the villains they were portrayed to be, though it is undeniable that they wielded enormous power. It was precisely during the era of these powerful business leaders that Harold Cole founded Fort Greenwold (FG), a firm that is currently one of the largest producers of paper and pulp with annual sales of $3.5 billion, Cole located his first plant in a rural town in New England, partly to create jobs for the many unemployed worker in the area. "Having a heart does not mean you can't make a buck", Harold was fond of saying. The firm has always been active in the affairs of the community and donates generously to local civic and charitable organizations. It also takes special pride in promoting a family atmosphere among its employees. Personnel experts believe that these policies are largely responsible for the enviable productivity record of FG's workers. For its first 80 years FG had an impressive record of growth in earnings and sales. But as the company grew, the willingness of top-level management to decentralize and delegate authority did not. The company stagnated until the appointment of the new chairman in recent years. The new chairman was shocked at the "nickel-and-dime stuff" that reached corporate headquarters, and he moved quickly to decentralize authority. One major change involved the company's capital budgeting procedures. FG had no formal mechanism for capital projects. The new chairman changed this and set up a six-person expenditures committee (EC) that would decide projects costing more than 200 000 USD. Smaller expenditures would be decided at the regional and local levels. Currently the EC is considering two alternatives for achieving a much-needed increase in the firm's production capacity. One option involves modernizing an existing mill in Lees Point, North Carolina. If the plant is not renovated soon, production would drop to 600 tons per day and the yearly cash flow would be 11 422 320 USD. (See Exhibit l for more complete information). The other alternative is to build a new mill at Midtown, North Carolina, which is 15 miles from Lee Point. Barbara Wadkins, a member of the EC, was responsible for estimating the cost and yearly cash flows from buildings the new paper mill at Midtown. She calculated the cost to be 618,8 million USD net of any tax considerations and including working capital, and estimated the yearly after-tax cash flow to be 107 728 000 USD. Exhibit 2 presents the information used to determine these figures. All committee members agree that theses numbers are quite reasonable". CONTROVERSY. The figures on modernizin the existing facility at Lees Point are more controversial, however, Information on this project was originally sent the by the management of the lees Point plant and is also presented in Exhibit 2. The controversy centers on the estimated tonnage per day of the plan and its per-unit variable cost. Wadkins politely pointed out that it would be "extremely difficult for an old facility like the one at Lees Point to achieve ouput of 1 600 tons per day". In contrast to Wadkins' mild reaction was the chairman's angry response. "You can forget it! I'll be the NBA's MVP before that plant puts out that tonnage!" Everyone on the EC knew aht the problem was. Management is from Lees Point and is worried that a new facility will reduce jobs. "I don't know why I got so angry. I should expect an estimate like this," said the new chairman. After much discussion the committee unanimously agreed that 1 200 tons per day was much more accurate and, if anythin, a bit optimistic. It was also decided that a per/unit variable cost of 282,1 USD per ton was appropriate instead of the original figure of 263,9USD per ton. With these changes the yearly cash flow after taxes was estimated to be 40 634 680 USD: this was considerably lower than the projectoin of 61 863 160 USD based on the figures sent by Lees Point management. MORE CONTROVERSY. Both projects are assumed to last 20 years. This is a relatively long time horizon for a capital budgeting project, but the company feels a paper mill is unlikely to become technologically obsolete since paper production techniques have changed very litle in the last century. At least one EC member, however, thinks that a 20-year period is too long for the "modernize-the-old" option. Past experience, he argues, indicates that revitalizing an existing facility will rarely extend its lif that much, and 15 years seems more probable. If so, he wonders if "we aren't being extremely charitable to the Lees Point plant. By my calculations, assuming a 20-year time horizon for this project adds 40 634 680 USD times5 or 203 173 400 to the total yearly cash flows. That's some largess!" The rest of the committee concedes that 20 years may be a bit long, but decides to retain this time period as a working hypothesis. EMPLOYEE CONCERNS Some EC members are worried about the impact on employee morale if the factory is relocated. "Apparently", says Wadkins, there is considerable opposition to closing down the old factory, judging from the inaccurate figures we received". It is noted, however that the move will "most certainly not cost anyone a job, but will, in fact, create new postions, including some relatively high-paying managerial ones. Nonethelss, it was obvious that the proposed relocation would impose costs on the employees. Many would either have to relocate to Midtrown or face a 30-mile round trip daily commute. Wadkins wondered if it was fair and appropriate to ask the employees to bear such costs, especially in light of the remarkable loyality the Lees Point employees had shown to the company. She notes that a large proportion of the employees have worked for FG for more than 10 years. One thing is clear, "remarks a subdued new chairman". "If we choose to relocate the plant, it is important that it does not appear to be some type of ivory-tower decision that would be inconsistent with the management philosphy we've promoted all these years. Barbara, I am sensitive to the issues you bring up. Employee morale and employe loyalty are very important consideratoins. Maybe we could work something out you know, like some type of moving allowance". The chairman alos reminded the committee that Midtown was the closest suitable site to Lees Point should the company move, QUESTIONS 1.a) Calculate the NPV net present value of modernizing the exisiting paper mill 1.b) Calculate the NPV of building a new paper mill 2.a) Calculate the IRR of each investment 2.b) Calculate the payback of each 3.a) Do the NPV and IRR methods give the same accept / reject signals? Explain why the NPV and IRR methods can give divergen signals when evaluatin mutually exclusive alternatives. at the appropriate life of a modernized factory is 15 years instead of 20.Evaluate the argument that assuming a 20-year time horizon for this project adds 40 634 680 USD times 5 or 203 173 400 USD to the yearly cash flows". 5. Based on your calculations in the previous questoins an information in the case, what decision do you recommend? Justify your choice. 6.a) Building a new mill requires 464,1 Million USD more than modernizing the old mill but will generate an extra 67 093 320 USD in yearly cash flow. Calculate the IRR on this incremental expenditure Compare your answers to the 12 % required rate of return. 6.b) Based on you answer in part a), suggest a decision rule for the IRR in evaluating mutually exclusive alternatives with different initial costs. EXHIBIT 1 Figures on Lees Point Facility without Renovation Plant life (years) Price per ton (5) 455 Tonnage per day 600 Variable cost/ton ($) 345.8 Fixed operating cost per year ($) 4,550,000 Depreciation per year Negligible After-tax yearly cash flow (5) 11,422, 320 Plant usage would be 360 days per year.. EXHIBIT 2 Information on Renovation and New Facility 435 455 2.200 Original) (Resised) New Facility Ou Facili Old Facility After-tax cost (S)" 618,800,000 154,700,000 154,700,000 Tax rate() Project Length (years) Price per ton (5) Tonnage per day 1.200 Variable cost per ton (5) 227.50 2639 2821 Fixed operating cost per year 15 52.200.000 19 $60.000 19.860.000 Fixed operating cost per ton (5) 65.91 34.48 4597 Depreciation method Depreciation life (years) Depreciation per year (5) 30,940,000 7,735,000 7,735,000 Depreciation per bon (5) 13 43 17.91 After-tax yearly cash flow (5) 107,728.000 61,963.160 20,634,580 Required return (%) 12 12 Recapture of working capital Negligible Negligible Negligible 'Net of tax considerations and including all working capital requirements. Each facility will be used 360 days per year. Includes depreciation 20 20 B (F 3 of 3 QUESTIONS 1. Calculate the NPV modumising the ing paper mill Calculate the NPV of building a new paperill 2. Calcule of each investment Calculate the payback of each. 3 ) Do the NPV and methods give the same acceptet signals bExplain why the NPV and methods can give divergent signal when evaluating mutually exce lematives 4. Suppose that the appropriate life of a modernized factory is 15 instead of 20 years. Evaluate the argument that assuming a 20-year time horizon for this project adds $40.634.680 times or $203.173.400 to the yearly cash flows." p The a rty code the time of th 36.7 mill- 5. Based on your calculations in the previous questions and information in the case, what decision do you recommend? Justify your choice. 6. (a) Building a new mill requires S164.1 million more than modernizing the old mill but will generate an extra $67,093.320 in yearly cash flow Calculate the IRR on this incremental expenditure. Compare your an swer to the 12 percent required retum (b) Based on your answer in part (a), suggest a decision rule for the IRR in evaluating mutually exclusive alteratives with different initial costs. BUSINESS CASE FORT GREENWOLD CAPITAL BUDGETING The public image of business in the latter part of the nineteenth century was hardly flattering. The adventures of so-called "Robber Barons" constantly made the headlines and their exploits matched those of their contemporaries in the Wild West. For example, J.P. Morgan hired an army of toughs to literally battle for a section of railroad near Binghamton, New York. And business leaders often expressed their contempt for the public interest, exemplified by such infamous comments as W.H. Vanderbilt's the public be damned" and J.P. Morgan's "I owe the public nothing". Recent research suggests that these individuals were probably not the villains they were portrayed to be, though it is undeniable that they wielded enormous power. It was precisely during the era of these powerful business leaders that Harold Cole founded Fort Greenwold (FG), a firm that is currently one of the largest producers of paper and pulp with annual sales of $3.5 billion, Cole located his first plant in a rural town in New England, partly to create jobs for the many unemployed worker in the area. "Having a heart does not mean you can't make a buck", Harold was fond of saying. The firm has always been active in the affairs of the community and donates generously to local civic and charitable organizations. It also takes special pride in promoting a family atmosphere among its employees. Personnel experts believe that these policies are largely responsible for the enviable productivity record of FG's workers. For its first 80 years FG had an impressive record of growth in earnings and sales. But as the company grew, the willingness of top-level management to decentralize and delegate authority did not. The company stagnated until the appointment of the new chairman in recent years. The new chairman was shocked at the "nickel-and-dime stuff" that reached corporate headquarters, and he moved quickly to decentralize authority. One major change involved the company's capital budgeting procedures. FG had no formal mechanism for capital projects. The new chairman changed this and set up a six-person expenditures committee (EC) that would decide projects costing more than 200 000 USD. Smaller expenditures would be decided at the regional and local levels. Currently the EC is considering two alternatives for achieving a much-needed increase in the firm's production capacity. One option involves modernizing an existing mill in Lees Point, North Carolina. If the plant is not renovated soon, production would drop to 600 tons per day and the yearly cash flow would be 11 422 320 USD. (See Exhibit l for more complete information). The other alternative is to build a new mill at Midtown, North Carolina, which is 15 miles from Lee Point. Barbara Wadkins, a member of the EC, was responsible for estimating the cost and yearly cash flows from buildings the new paper mill at Midtown. She calculated the cost to be 618,8 million USD net of any tax considerations and including working capital, and estimated the yearly after-tax cash flow to be 107 728 000 USD. Exhibit 2 presents the information used to determine these figures. All committee members agree that theses numbers are quite reasonable". CONTROVERSY. The figures on modernizin the existing facility at Lees Point are more controversial, however, Information on this project was originally sent the by the management of the lees Point plant and is also presented in Exhibit 2. The controversy centers on the estimated tonnage per day of the plan and its per-unit variable cost. Wadkins politely pointed out that it would be "extremely difficult for an old facility like the one at Lees Point to achieve ouput of 1 600 tons per day". In contrast to Wadkins' mild reaction was the chairman's angry response. "You can forget it! I'll be the NBA's MVP before that plant puts out that tonnage!" Everyone on the EC knew aht the problem was. Management is from Lees Point and is worried that a new facility will reduce jobs. "I don't know why I got so angry. I should expect an estimate like this," said the new chairman. After much discussion the committee unanimously agreed that 1 200 tons per day was much more accurate and, if anythin, a bit optimistic. It was also decided that a per/unit variable cost of 282,1 USD per ton was appropriate instead of the original figure of 263,9USD per ton. With these changes the yearly cash flow after taxes was estimated to be 40 634 680 USD: this was considerably lower than the projectoin of 61 863 160 USD based on the figures sent by Lees Point management. MORE CONTROVERSY. Both projects are assumed to last 20 years. This is a relatively long time horizon for a capital budgeting project, but the company feels a paper mill is unlikely to become technologically obsolete since paper production techniques have changed very litle in the last century. At least one EC member, however, thinks that a 20-year period is too long for the "modernize-the-old" option. Past experience, he argues, indicates that revitalizing an existing facility will rarely extend its lif that much, and 15 years seems more probable. If so, he wonders if "we aren't being extremely charitable to the Lees Point plant. By my calculations, assuming a 20-year time horizon for this project adds 40 634 680 USD times5 or 203 173 400 to the total yearly cash flows. That's some largess!" The rest of the committee concedes that 20 years may be a bit long, but decides to retain this time period as a working hypothesis. EMPLOYEE CONCERNS Some EC members are worried about the impact on employee morale if the factory is relocated. "Apparently", says Wadkins, there is considerable opposition to closing down the old factory, judging from the inaccurate figures we received". It is noted, however that the move will "most certainly not cost anyone a job, but will, in fact, create new postions, including some relatively high-paying managerial ones. Nonethelss, it was obvious that the proposed relocation would impose costs on the employees. Many would either have to relocate to Midtrown or face a 30-mile round trip daily commute. Wadkins wondered if it was fair and appropriate to ask the employees to bear such costs, especially in light of the remarkable loyality the Lees Point employees had shown to the company. She notes that a large proportion of the employees have worked for FG for more than 10 years. One thing is clear, "remarks a subdued new chairman". "If we choose to relocate the plant, it is important that it does not appear to be some type of ivory-tower decision that would be inconsistent with the management philosphy we've promoted all these years. Barbara, I am sensitive to the issues you bring up. Employee morale and employe loyalty are very important consideratoins. Maybe we could work something out you know, like some type of moving allowance". The chairman alos reminded the committee that Midtown was the closest suitable site to Lees Point should the company move, QUESTIONS 1.a) Calculate the NPV net present value of modernizing the exisiting paper mill 1.b) Calculate the NPV of building a new paper mill 2.a) Calculate the IRR of each investment 2.b) Calculate the payback of each 3.a) Do the NPV and IRR methods give the same accept / reject signals? Explain why the NPV and IRR methods can give divergen signals when evaluatin mutually exclusive alternatives. at the appropriate life of a modernized factory is 15 years instead of 20.Evaluate the argument that assuming a 20-year time horizon for this project adds 40 634 680 USD times 5 or 203 173 400 USD to the yearly cash flows". 5. Based on your calculations in the previous questoins an information in the case, what decision do you recommend? Justify your choice. 6.a) Building a new mill requires 464,1 Million USD more than modernizing the old mill but will generate an extra 67 093 320 USD in yearly cash flow. Calculate the IRR on this incremental expenditure Compare your answers to the 12 % required rate of return. 6.b) Based on you answer in part a), suggest a decision rule for the IRR in evaluating mutually exclusive alternatives with different initial costs. EXHIBIT 1 Figures on Lees Point Facility without Renovation Plant life (years) Price per ton (5) 455 Tonnage per day 600 Variable cost/ton ($) 345.8 Fixed operating cost per year ($) 4,550,000 Depreciation per year Negligible After-tax yearly cash flow (5) 11,422, 320 Plant usage would be 360 days per year.. EXHIBIT 2 Information on Renovation and New Facility 435 455 2.200 Original) (Resised) New Facility Ou Facili Old Facility After-tax cost (S)" 618,800,000 154,700,000 154,700,000 Tax rate() Project Length (years) Price per ton (5) Tonnage per day 1.200 Variable cost per ton (5) 227.50 2639 2821 Fixed operating cost per year 15 52.200.000 19 $60.000 19.860.000 Fixed operating cost per ton (5) 65.91 34.48 4597 Depreciation method Depreciation life (years) Depreciation per year (5) 30,940,000 7,735,000 7,735,000 Depreciation per bon (5) 13 43 17.91 After-tax yearly cash flow (5) 107,728.000 61,963.160 20,634,580 Required return (%) 12 12 Recapture of working capital Negligible Negligible Negligible 'Net of tax considerations and including all working capital requirements. Each facility will be used 360 days per year. Includes depreciation 20 20 B (F 3 of 3 QUESTIONS 1. Calculate the NPV modumising the ing paper mill Calculate the NPV of building a new paperill 2. Calcule of each investment Calculate the payback of each. 3 ) Do the NPV and methods give the same acceptet signals bExplain why the NPV and methods can give divergent signal when evaluating mutually exce lematives 4. Suppose that the appropriate life of a modernized factory is 15 instead of 20 years. Evaluate the argument that assuming a 20-year time horizon for this project adds $40.634.680 times or $203.173.400 to the yearly cash flows." p The a rty code the time of th 36.7 mill- 5. Based on your calculations in the previous questions and information in the case, what decision do you recommend? Justify your choice. 6. (a) Building a new mill requires S164.1 million more than modernizing the old mill but will generate an extra $67,093.320 in yearly cash flow Calculate the IRR on this incremental expenditure. Compare your an swer to the 12 percent required retum (b) Based on your answer in part (a), suggest a decision rule for the IRR in evaluating mutually exclusive alteratives with different initial costsStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started