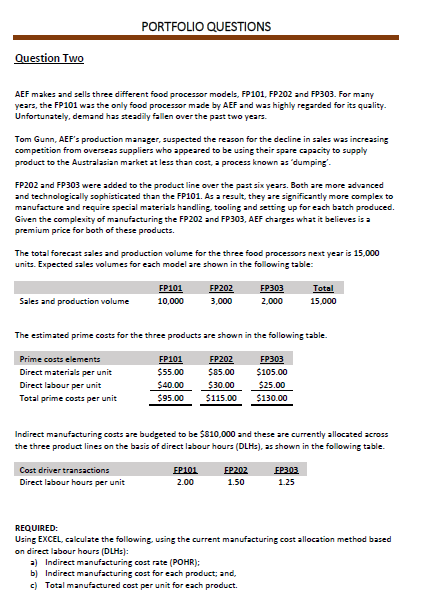

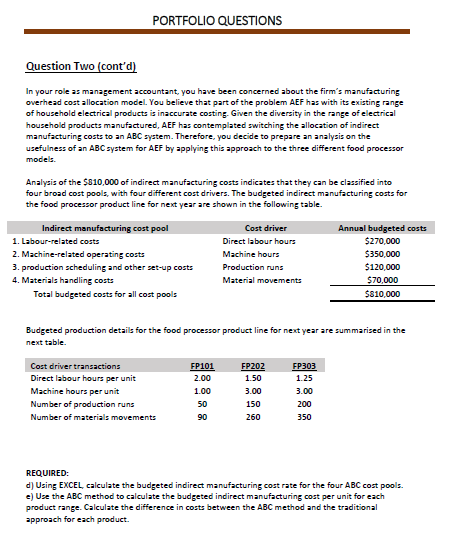

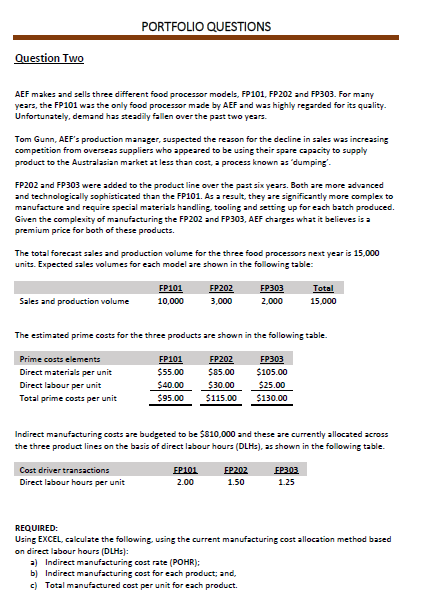

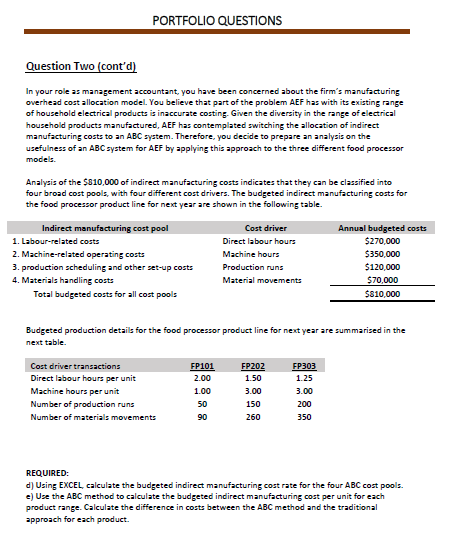

PORTFOLIO QUESTIONS Question Two AEF makes and sells three different food processor models, FP101, FP202 and FP303. For many years, the FP101 was the only food processor made by AEF and was highly regarded for its quality Unfortunately, demand has steadily fallen over the past two years. Tom Gunn, AEF's production manager, suspected the reason for the decline in sales was increasing competition from overseas suppliers who appeared to be using their spare capacity to supply product to the Australasian market at less than cost, a process known as 'dumping FP202 and FP303 were added to the product line over the past six years. Both are more advanced and technologically sophisticated than the FP101. As a result, they are significantly more complex to manufacture and require special materials handling, tooling and setting up for each batch produced. Given the complexity of manufacturing the FP202 and FP303, AEF charges what it believes is a premium price for both of these products. The total forecast sales and production volume for the three food processors next year is 15,000 units. Expected sales volumes for each model are shown in the following table: FP101 10,000 FP202 EP303 2,000 Total 15.000 Sales and production volume 3,000 The estimated prime costs for the three products are shown in the following table. Prime costs elements Direct materials per unit Direct labour per unit Total prime costs per unit FP101 $55.00 $40.00 $95.00 FP202 $85.00 $30.00 $115.00 FP303 $105.00 $25.00 $130.00 Indirect manufacturing costs are budgeted to be $810,000 and these are currently allocated across the three product lines on the basis of direct labour hours (DLHs), as shown in the following table. Cost driver transactions Direct labour hours per unit FP101 2.00 EP202 1.50 EP303 1.25 REQUIRED: Using EXCEL, calculate the following using the current manufacturing cost allocation method based on direct labour hours (DLHs): a) Indirect manufacturing cost rate (POHR); b) Indirect manufacturing cost for each product; and, c) Total manufactured cost per unit for each product. PORTFOLIO QUESTIONS Question Two (cont'd) In your role as management accountant, you have been concerned about the firm's manufacturing overhead cost allocation model. You believe that part of the problem AEF has with its existing range of household electrical products is inaccurate costing. Given the diversity in the range of electrical household products manufactured, AEF has contemplated switching the allocation of indirect manufacturing costs to an ABC system. Therefore, you decide to prepare an analysis on the usefulness of an ABC system for AEF by applying this approach to the three different food processor models. Analysis of the 5810,000 of indirect manufacturing costs indicates that they can be classified into four broad cost pools, with four different cost drivers. The budgeted indirect manufacturing costs for the food processor product line for next year are shown in the following table. Indirect manufacturing cost pool 1. Labour-related costs 2. Machine-related operating costs 3. production scheduling and other set-up costs 4. Materials handling costs Total budgeted costs for all cost pools Cost driver Direct labour hours Machine hours Production runs Material movements Annual budgeted costs $270,000 $350,000 $120,000 $70,000 $810,000 Budgeted production details for the food processor product line for next year are summarised in the next table. Cost driver transactions Direct labour hours per unit Machine hours per unit Number of production runs Number of materials movements FP101 2.00 1.00 50 90 FP202 1.50 3.00 150 260 FP303 1.25 3.00 200 350 REQUIRED: d) Using EXCEL, calculate the budgeted indirect manufacturing cost rate for the four ABC cost pools. e) Use the ABC method to calculate the budgeted indirect manufacturing cost per unit for each product range. Calculate the difference in costs between the ABC method and the traditional approach for each product