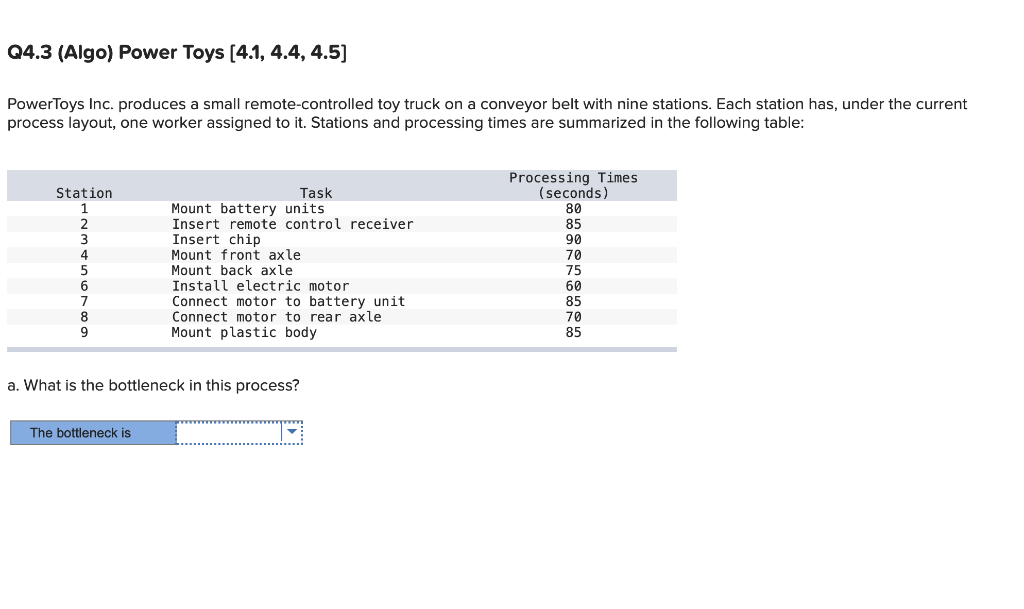

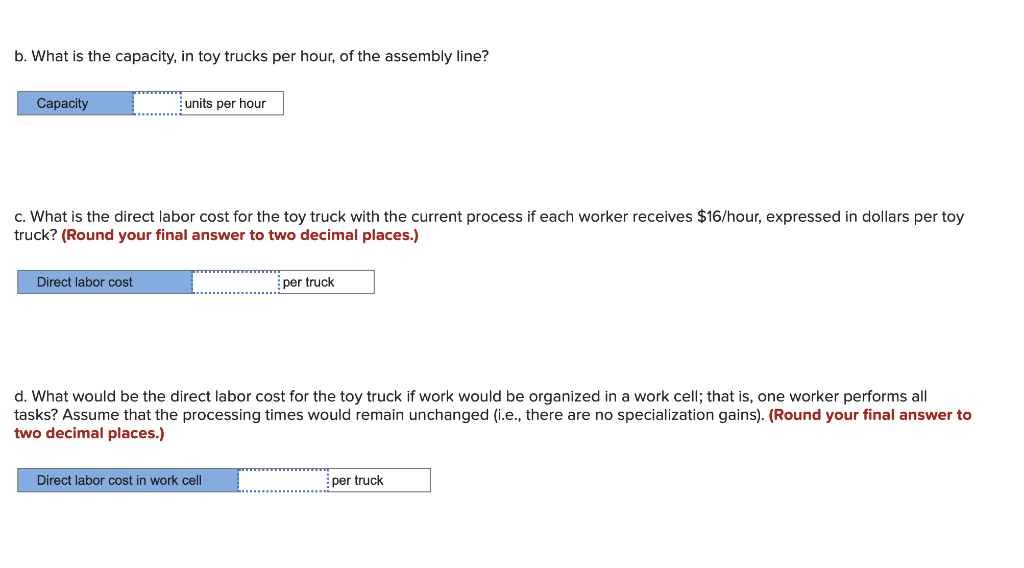

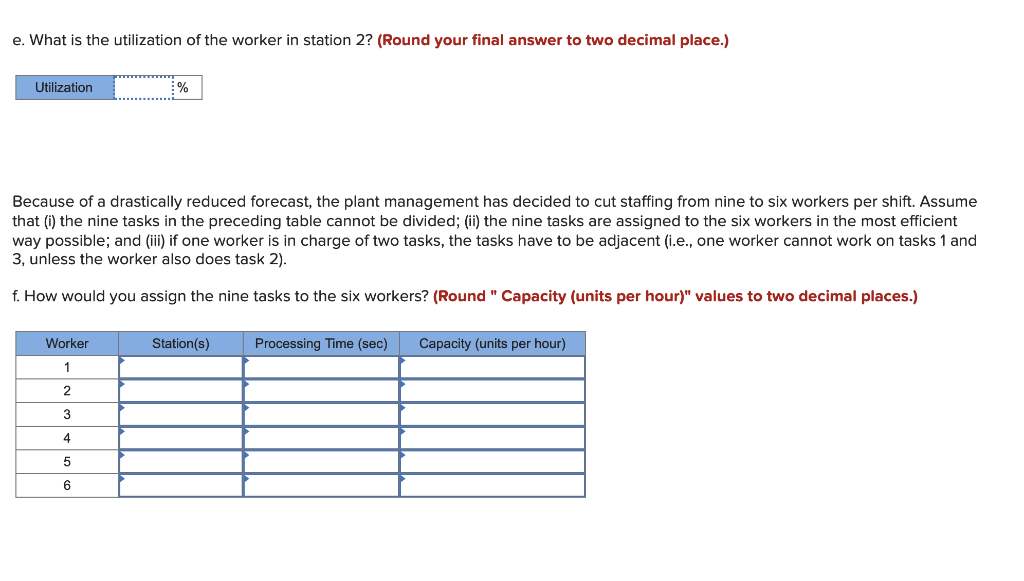

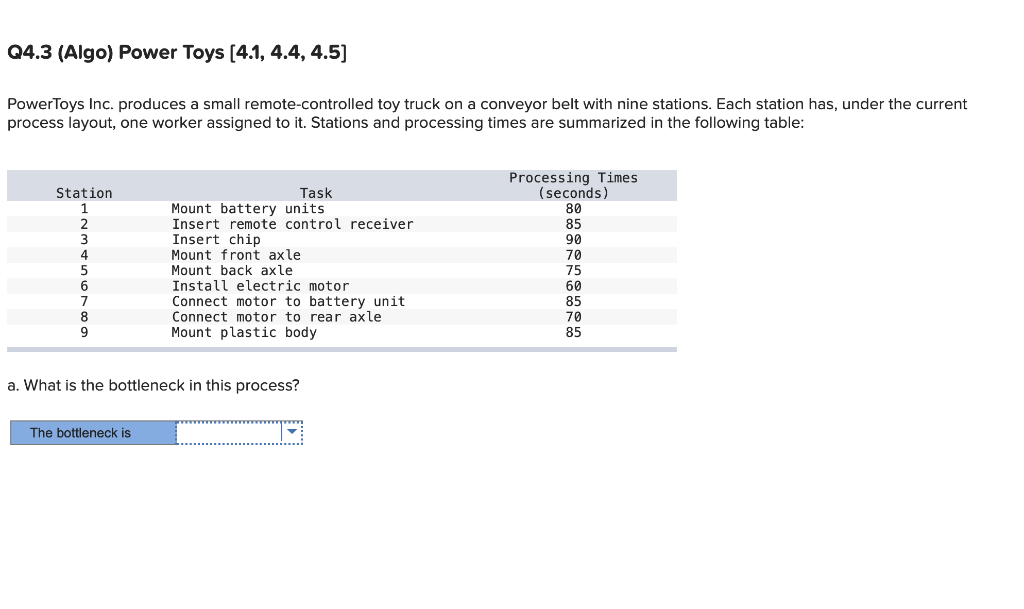

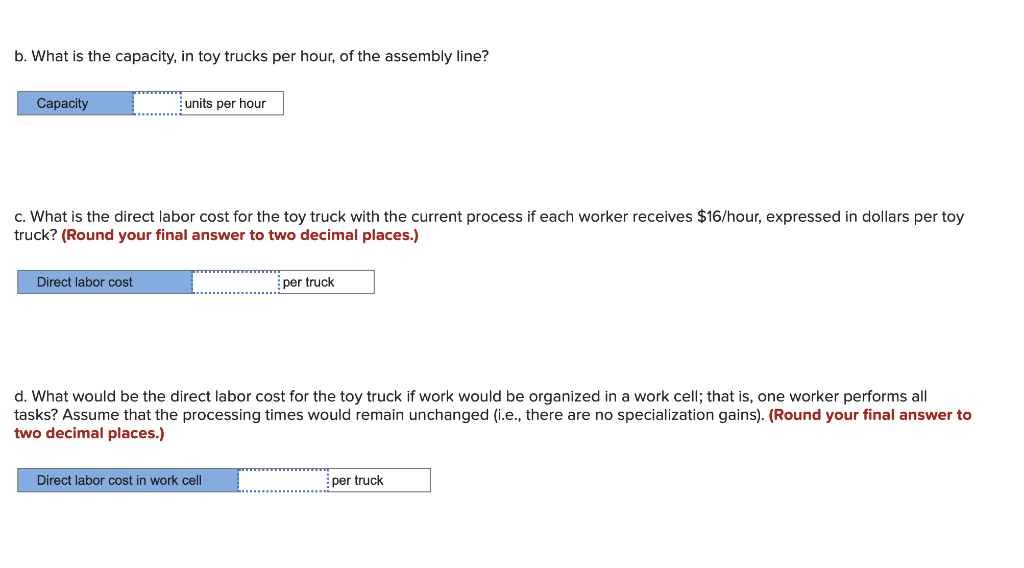

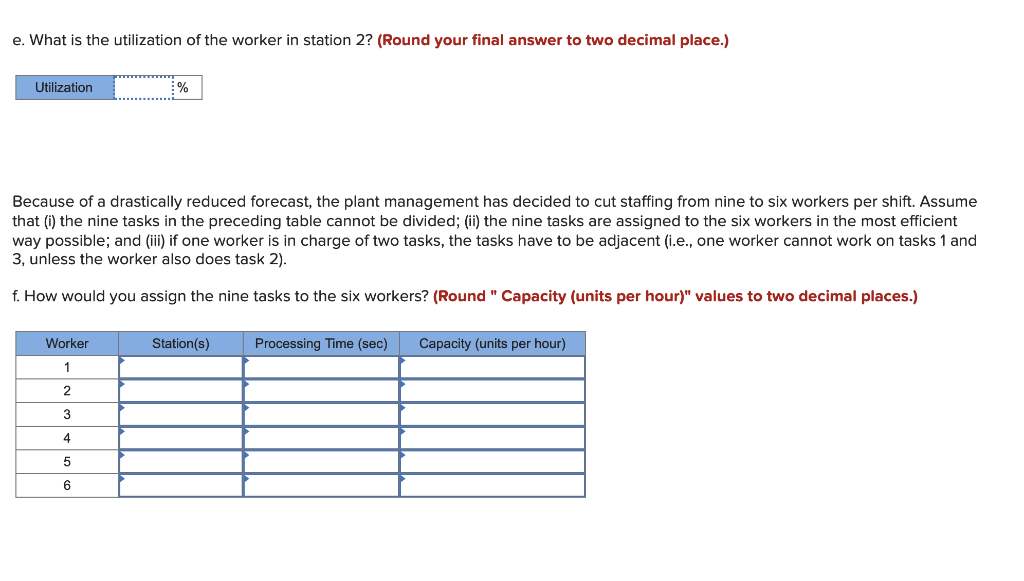

PowerToys Inc. produces a small remote-controlled toy truck on a conveyor belt with nine stations. Each station has, under the current process layout, one worker assigned to it. Stations and processing times are summarized in the following table: a. What is the bottleneck in this process? b. What is the capacity, in toy trucks per hour, of the assembly line? c. What is the direct labor cost for the toy truck with the current process if each worker receives $16/ hour, expressed in dollars per toy truck? (Round your final answer to two decimal places.) d. What would be the direct labor cost for the toy truck if work would be organized in a work cell; that is, one worker performs all tasks? Assume that the processing times would remain unchanged (i.e., there are no specialization gains). (Round your final answer to two decimal places.) e. What is the utilization of the worker in station 2? (Round your final answer to two decimal place.) Because of a drastically reduced forecast, the plant management has decided to cut staffing from nine to six workers per shift. Assume that (i) the nine tasks in the preceding table cannot be divided; (ii) the nine tasks are assigned to the six workers in the most efficient way possible; and (iii) if one worker is in charge of two tasks, the tasks have to be adjacent (i.e., one worker cannot wask 1 and 3, unless the worker also does task 2). f. How would you assign the nine tasks to the six workers? (Round "Capacity (units per hour)" values to two decimal places.) g. What is the new capacity of the line (in toy trucks per hour)? (Round your final answer to two decimal places.) PowerToys Inc. produces a small remote-controlled toy truck on a conveyor belt with nine stations. Each station has, under the current process layout, one worker assigned to it. Stations and processing times are summarized in the following table: a. What is the bottleneck in this process? b. What is the capacity, in toy trucks per hour, of the assembly line? c. What is the direct labor cost for the toy truck with the current process if each worker receives $16/ hour, expressed in dollars per toy truck? (Round your final answer to two decimal places.) d. What would be the direct labor cost for the toy truck if work would be organized in a work cell; that is, one worker performs all tasks? Assume that the processing times would remain unchanged (i.e., there are no specialization gains). (Round your final answer to two decimal places.) e. What is the utilization of the worker in station 2? (Round your final answer to two decimal place.) Because of a drastically reduced forecast, the plant management has decided to cut staffing from nine to six workers per shift. Assume that (i) the nine tasks in the preceding table cannot be divided; (ii) the nine tasks are assigned to the six workers in the most efficient way possible; and (iii) if one worker is in charge of two tasks, the tasks have to be adjacent (i.e., one worker cannot wask 1 and 3, unless the worker also does task 2). f. How would you assign the nine tasks to the six workers? (Round "Capacity (units per hour)" values to two decimal places.) g. What is the new capacity of the line (in toy trucks per hour)? (Round your final answer to two decimal places.)