Question: Precision Worldwide Case: What are the decision problem and the goal of the decision? Which is more profitable, steel or plastic rings? From your initial

Precision Worldwide Case:

- What are the decision problem and the goal of the decision?

- Which is more profitable, steel or plastic rings?

- From your initial reading of the case, what would you do?

- What actions should Hans Thorborg take? Why?

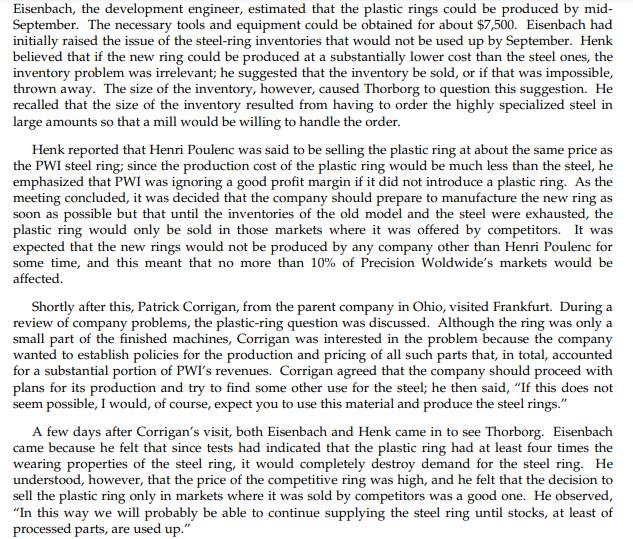

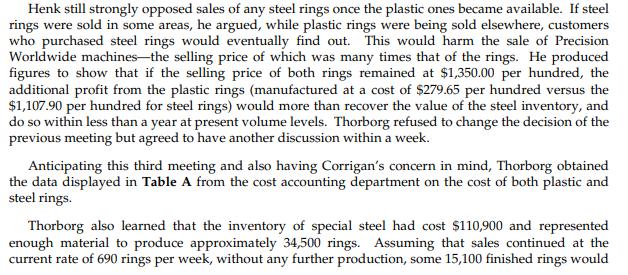

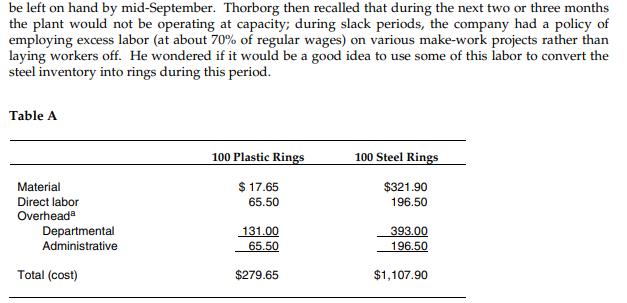

In late May 2004, Hans Thorborg, the general manager of the German plant of Precision Worldwide, Inc. (PWI), scheduled an afternoon meeting with his sales manager, accountant, and development engineer to discuss the introduction by the French firm Henri Poulenc (a competitor) of a plastic ring substitute for the steel retaining rings presently used in certain machines sold by Precision Worldwide. The plastic ring, new to the market, not only had a much longer life than the PWI steel ring but also apparently had a much lower manufacturing cost. Thorborg's problem stemmed from PWI's large quantity of steel rings on hand and the substantial inventory of special steel that had been purchased for their manufacture. After a thorough survey, he had found that the special steel could not be sold, even for scrap; the total book value of these inventories exceeded $390,000. For nearly 90 years PWI had manufactured industrial machines and equipment for sale in numerous countries. The particular machines involved in Thorborg's dilemma were made only at the company's plant in Frankfurt, Germany, which employed more than one thousand people. The different models were priced between $18,900 and $28,900 and were sold by a separate sales organization. Repair and replacement parts, which accounted for a substantial part of the company's business, were sold separately. As with the steel rings, these parts could often also be used on similar machines manufactured by competitors. The company's head office was in Toledo, Ohio, U.S.A. In general, plants outside the United States were allowed considerable leeway in administering their own affairs; the corporate headquarters, however, was easily accessible by telephone, email, or during executive visits to the individual plants. In the late 1990s, competition had increased. Japanese manufacturers, with low-priced spare parts, had successfully entered the field. Other companies had appeared with lower-quality and lower-priced machines. There was little doubt that future competition would be more intense. The steel ring manufactured by PWI had a normal life of about two months, depending upon the extent to which the machine was used. A worn-out ring could be replaced in a few seconds, and although different models of the machines required from two to six rings, the rings were usually replaced individually as they wore out.

Step by Step Solution

3.53 Rating (160 Votes )

There are 3 Steps involved in it

Current Situation Precision Worldwide Incs PWI business model is manufacturing industrial machines and equipment worldwide In addition to manufacturing industrial machines and equipment PWI generates ... View full answer

Get step-by-step solutions from verified subject matter experts