Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Problem 11-6 (Algo) Manager Chris Channing of Fabric Mills, Inc., has developed the forecast shown in the table for bolts of cloth. The figures are

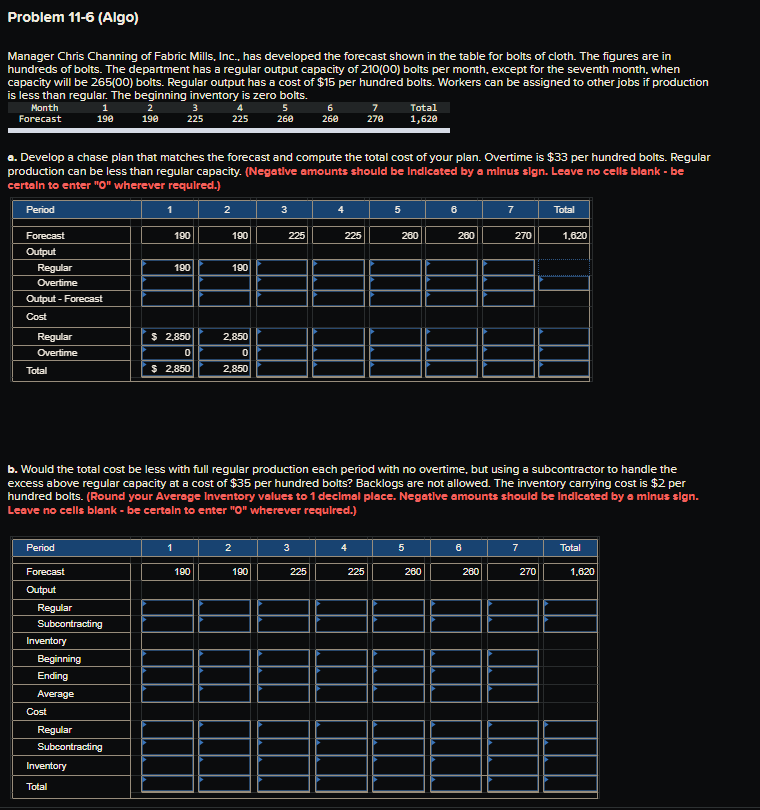

Problem 11-6 (Algo) Manager Chris Channing of Fabric Mills, Inc., has developed the forecast shown in the table for bolts of cloth. The figures are in hundreds of bolts. The department has a regular output capacity of 210(00) bolts per month, except for the seventh month, when capacity will be 265(00) bolts. Regular output has a cost of $15 per hundred bolts. Workers can be assigned to other jobs if production is less than regular. The beginning inventory is zero bolts. MonthForecast1190219032254225526062607270Total1,620 a. Develop a chase plan that matches the forecast and compute the total cost of your plan. Overtime is $33 per hundred bolts. Regular production can be less than regular capacity. (Negetlve amounts should be Indlceted by a minus slgn. Leave no cells blenk - be certaln to enter "o" wherever requlred.) b. Would the total cost be less with full regular production each period with no overtime, but using a subcontractor to handle the excess above regular capacity at a cost of $35 per hundred bolts? Backlogs are not allowed. The inventory carrying cost is $2 per hundred bolts. (Round your Averege lnventory values to 1 declmal place. Negatlve amounts should be Indlceted by a minus slgn. Leave no cells blenk - be certaln to enter "O" wherever requlred.) Problem 11-6 (Algo) Manager Chris Channing of Fabric Mills, Inc., has developed the forecast shown in the table for bolts of cloth. The figures are in hundreds of bolts. The department has a regular output capacity of 210(00) bolts per month, except for the seventh month, when capacity will be 265(00) bolts. Regular output has a cost of $15 per hundred bolts. Workers can be assigned to other jobs if production is less than regular. The beginning inventory is zero bolts. MonthForecast1190219032254225526062607270Total1,620 a. Develop a chase plan that matches the forecast and compute the total cost of your plan. Overtime is $33 per hundred bolts. Regular production can be less than regular capacity. (Negetlve amounts should be Indlceted by a minus slgn. Leave no cells blenk - be certaln to enter "o" wherever requlred.) b. Would the total cost be less with full regular production each period with no overtime, but using a subcontractor to handle the excess above regular capacity at a cost of $35 per hundred bolts? Backlogs are not allowed. The inventory carrying cost is $2 per hundred bolts. (Round your Averege lnventory values to 1 declmal place. Negatlve amounts should be Indlceted by a minus slgn. Leave no cells blenk - be certaln to enter "O" wherever requlred.)

Problem 11-6 (Algo) Manager Chris Channing of Fabric Mills, Inc., has developed the forecast shown in the table for bolts of cloth. The figures are in hundreds of bolts. The department has a regular output capacity of 210(00) bolts per month, except for the seventh month, when capacity will be 265(00) bolts. Regular output has a cost of $15 per hundred bolts. Workers can be assigned to other jobs if production is less than regular. The beginning inventory is zero bolts. MonthForecast1190219032254225526062607270Total1,620 a. Develop a chase plan that matches the forecast and compute the total cost of your plan. Overtime is $33 per hundred bolts. Regular production can be less than regular capacity. (Negetlve amounts should be Indlceted by a minus slgn. Leave no cells blenk - be certaln to enter "o" wherever requlred.) b. Would the total cost be less with full regular production each period with no overtime, but using a subcontractor to handle the excess above regular capacity at a cost of $35 per hundred bolts? Backlogs are not allowed. The inventory carrying cost is $2 per hundred bolts. (Round your Averege lnventory values to 1 declmal place. Negatlve amounts should be Indlceted by a minus slgn. Leave no cells blenk - be certaln to enter "O" wherever requlred.) Problem 11-6 (Algo) Manager Chris Channing of Fabric Mills, Inc., has developed the forecast shown in the table for bolts of cloth. The figures are in hundreds of bolts. The department has a regular output capacity of 210(00) bolts per month, except for the seventh month, when capacity will be 265(00) bolts. Regular output has a cost of $15 per hundred bolts. Workers can be assigned to other jobs if production is less than regular. The beginning inventory is zero bolts. MonthForecast1190219032254225526062607270Total1,620 a. Develop a chase plan that matches the forecast and compute the total cost of your plan. Overtime is $33 per hundred bolts. Regular production can be less than regular capacity. (Negetlve amounts should be Indlceted by a minus slgn. Leave no cells blenk - be certaln to enter "o" wherever requlred.) b. Would the total cost be less with full regular production each period with no overtime, but using a subcontractor to handle the excess above regular capacity at a cost of $35 per hundred bolts? Backlogs are not allowed. The inventory carrying cost is $2 per hundred bolts. (Round your Averege lnventory values to 1 declmal place. Negatlve amounts should be Indlceted by a minus slgn. Leave no cells blenk - be certaln to enter "O" wherever requlred.) Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started