Answered step by step

Verified Expert Solution

Question

1 Approved Answer

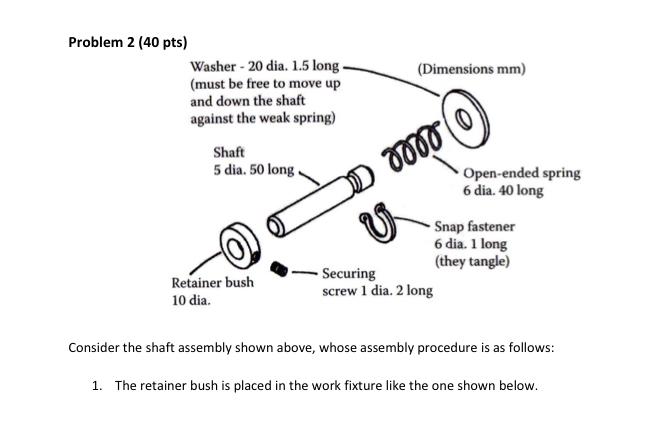

Problem 2 (40 pts) Washer - 20 dia. 1.5 long. (must be free to move up and down the shaft against the weak spring)

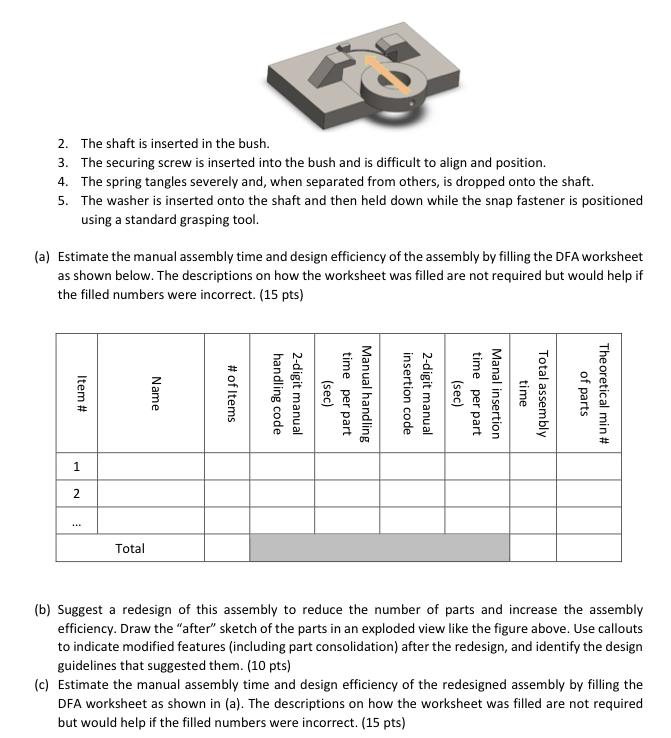

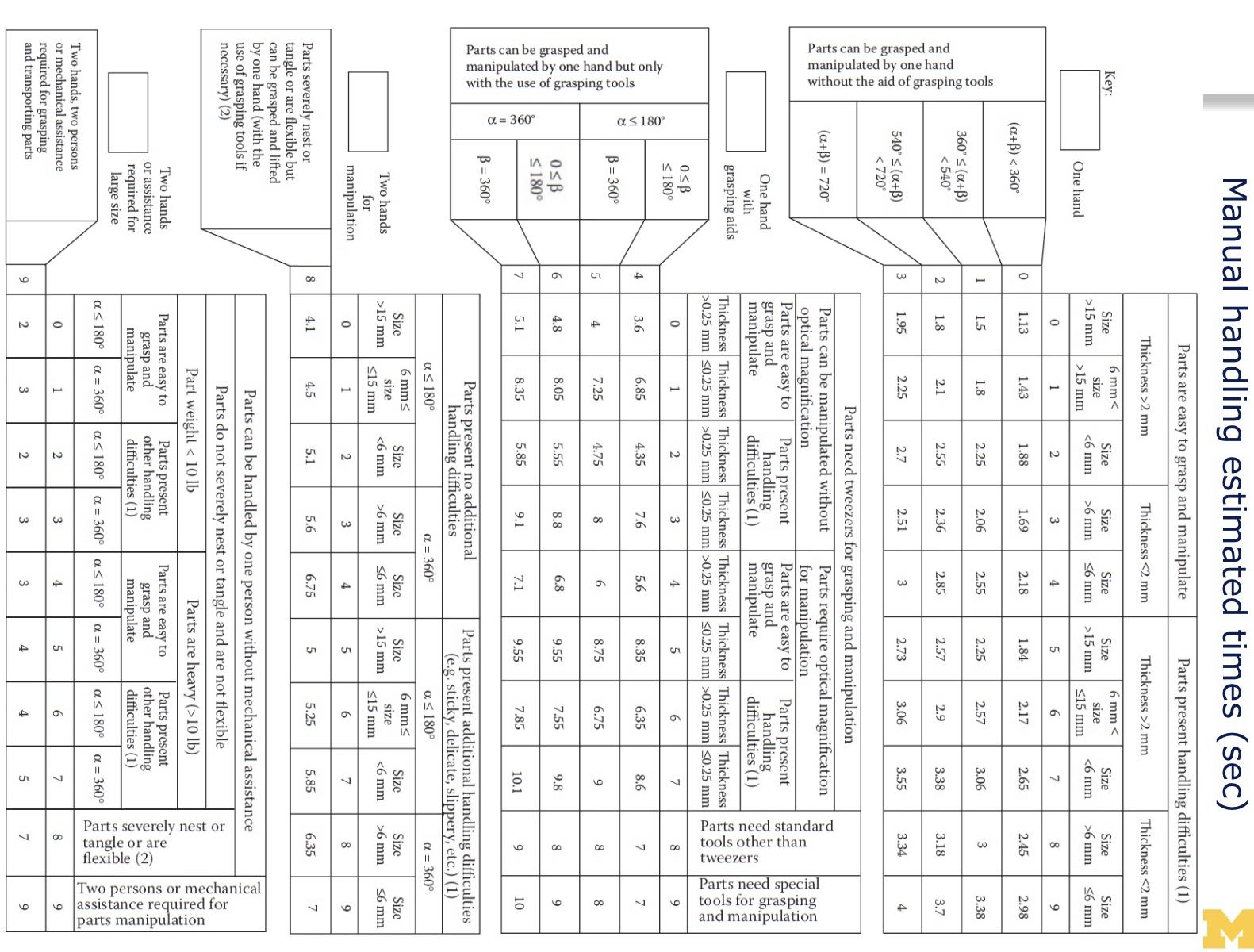

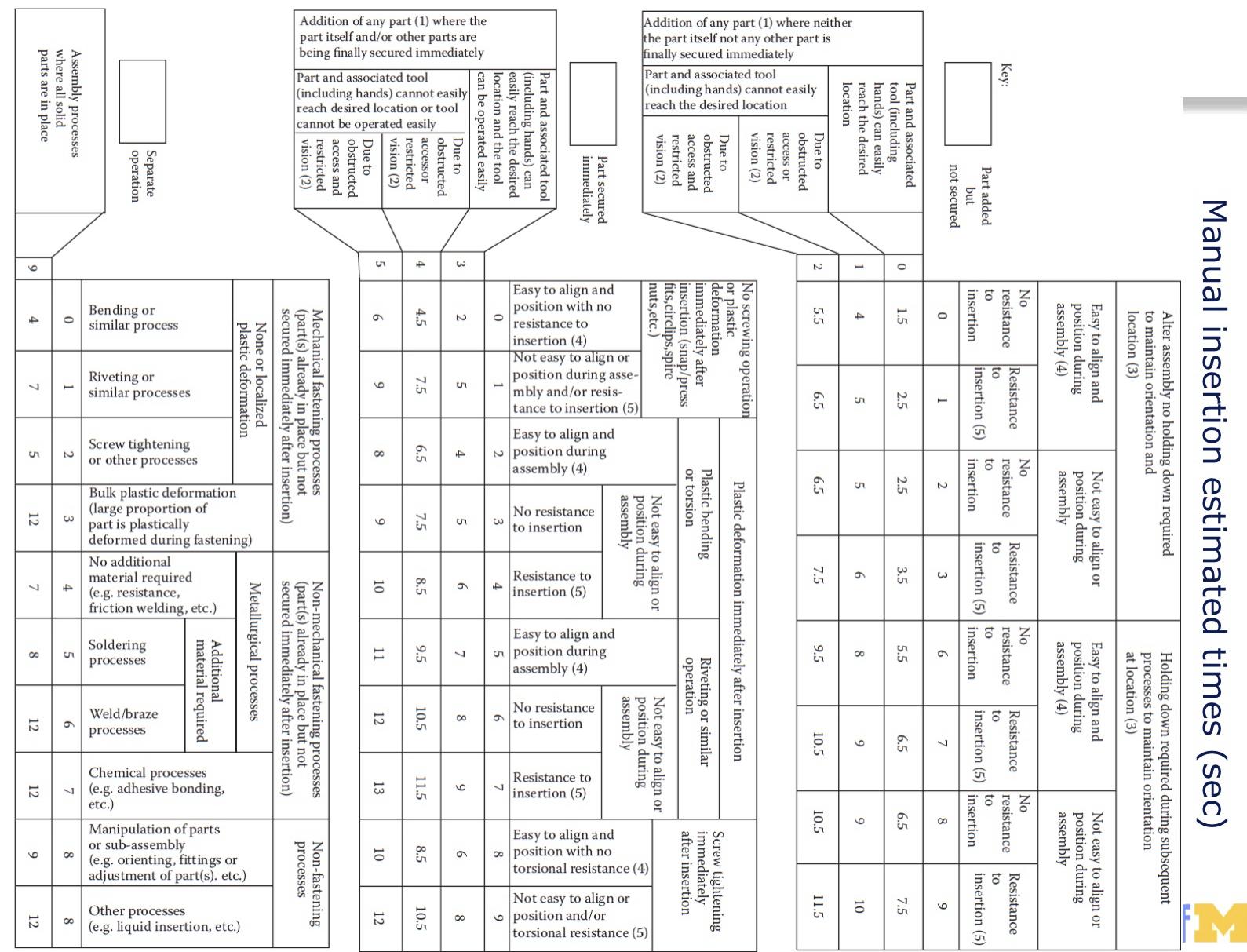

Problem 2 (40 pts) Washer - 20 dia. 1.5 long. (must be free to move up and down the shaft against the weak spring) Shaft 5 dia. 50 long (Dimensions mm) 0000 Open-ended spring 6 dia. 40 long Snap fastener 6 dia. 1 long (they tangle) Retainer bush 10 dia. Securing screw 1 dia. 2 long Consider the shaft assembly shown above, whose assembly procedure is as follows: 1. The retainer bush is placed in the work fixture like the one shown below. 2. The shaft is inserted in the bush. 3. The securing screw is inserted into the bush and is difficult to align and position. 4. The spring tangles severely and, when separated from others, is dropped onto the shaft. 5. The washer is inserted onto the shaft and then held down while the snap fastener is positioned using a standard grasping tool. (a) Estimate the manual assembly time and design efficiency of the assembly by filling the DFA worksheet as shown below. The descriptions on how the worksheet was filled are not required but would help if the filled numbers were incorrect. (15 pts) Item # 1 2 Name # of Items (b) Suggest a redesign of this assembly to reduce the number of parts and increase the assembly efficiency. Draw the "after" sketch of the parts in an exploded view like the figure above. Use callouts to indicate modified features (including part consolidation) after the redesign, and identify the design guidelines that suggested them. (10 pts) (c) Estimate the manual assembly time and design efficiency of the redesigned assembly by filling the DFA worksheet as shown in (a). The descriptions on how the worksheet was filled are not required but would help if the filled numbers were incorrect. (15 pts) Total Manual handling estimated times (sec) Parts are easy to grasp and manipulate Parts present handling difficulties (1) Thickness >2 mm Thickness 2 mm Thickness >2 mm Thickness 2 mm Key: Size >15 mm One hand 6 mm size >15 mm Size Size 6 mm Size 6 mm Size >15 mm 6 mm size Size Size 6 mm Size 6 mm 15 mm 0 1 2 3 4 5 6 7 8 9 0 1.13 1.43 1.88 1.69 2.18 1.84 2.17 2.65 2.45 2.98 (+) < 360 1 15 1.5 1.8 2.25 2.06 2.55 2.25 2.57 3.06 3 3.38 360 (+) 0.25 mm 0.25 mm >0.25 mm 0.25 mm >0.25 mm 0.25 mm grasp and manipulate handling Parts need standard tools other than tweezers or grasping Parts need special tools for and manipulation 0 180 0 1 2 3 4 5 6 7 8 9 4 3.6 6.85 4.35 7.6 5.6 8.35 6.35 8.6 7 7 B = 360 5 4 7.25 4.75 8 6 8.75 6.75 9 8 8 6 4.8 8.05 5.55 8.8 6.8 9.55 7.55 9.8 8 9 180 7 5.1 8.35 5.85 9.1 7.1 9.55 7.85 10.1 9 10 10 B = 360 Parts severely nest or Two hands for manipulation tangle or are flexible but can be grasped and lifted by one hand (with the use of grasping tools if necessary) (2) Parts present no additional handling difficulties Parts present additional handling difficulties (e.g. sticky, delicate, slippery, etc.) (1) = 1800 = 360 a180 = 360 6 mm 6 mm Size Size size >15 mm 6 mm Size 6 mm Size >15 mm Size Size size 6 mm Size 6 mm

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started