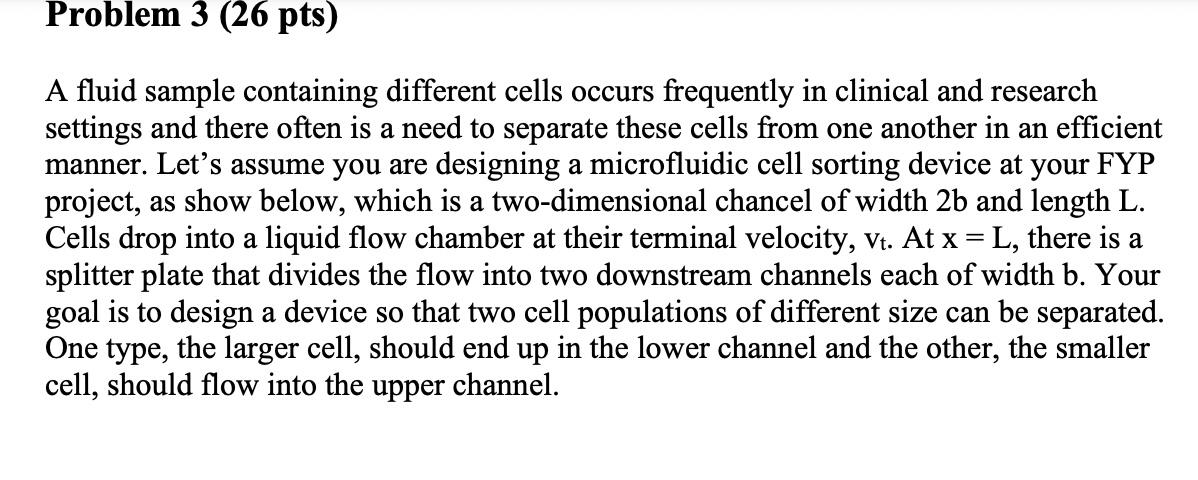

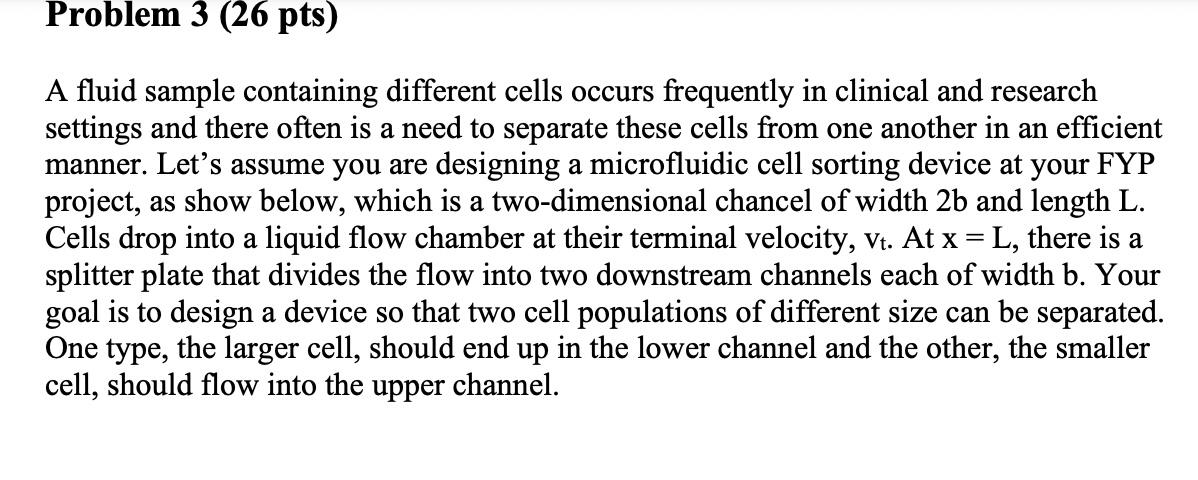

Problem 3 (26 pts) A fluid sample containing different cells occurs frequently in clinical and research settings and there often is a need to separate these cells from one another in an efficient manner. Let's assume you are designing a microfluidic cell sorting device at your FYP project, as show below, which is a two-dimensional chancel of width 2b and length L. Cells drop into a liquid flow chamber at their terminal velocity, Vt. At x=L, there is a splitter plate that divides the flow into two downstream channels each of width b. Your goal is to design a device so that two cell populations of different size can be separated. One type, the larger cell, should end up in the lower channel and the other, the smaller cell, should flow into the upper channel. : V. b. flow splitter L CBE's FYP Project: Designing a cell sorting device with a split channel. Like what we discussed in the class, the channel conveys a flow in the x direction which has a parabolic profile with respect to y. Um is the maximum velocity at the center of the channel. (i) Can you write down the velocity profile u as a function of y? Derivation is not necessary. (4 pts) (ii) You may assume that the cell maintains its constant y-velocity, Vt, but its x- velocity matches the fluid's x-velocity. Can you write down the governing equations for the cell positions (Xp, yp) in terms of ODE (ie dxp/dt=..., dyp/dt=...). Also specify initial conditions for this problem. In addition to the variables to be solved, your equations could contain parameters Um, b, Vt. As 3 soon the values of the parameters are given, your ODE should be in an expression that could be solved by using MATLAB or Polymath software. Although vt for large and small cells are different, you don't need to worry about it at this question. The ODEs you setup can be equally applicable for large or small cells as long as the terminal velocity Vt is given. (14 pts) (iii) a Now let's do the quantitative analysis. Top inlet of cell solutions enters the channel with a volumetric flow rate Q of 0.01 cm3/sec with a uniform cell mixture solution of cell density (104 cells/cm) and 60% large cells and 40% small cells, the channel length L is 5 cm and half width of the channel b is 5 mm. If large cells can all go underneath center line of the chancel before traveling to the flow splitter, what is the cell flow rate (cells/min) of the large cells in the bottom half of the flow splitter? If the large and small cells are all spherical shape with the same mass density and the diameter of the large cells is 2 times of the small cells, what is the terminal velocity of the large cells if the small cell has a terminal velocity Vt of 500 um/sec? Justify your answer. Hint: You may assume that microfluidic channel flow has a Re smaller than one. (8 pts) Problem 3 (26 pts) A fluid sample containing different cells occurs frequently in clinical and research settings and there often is a need to separate these cells from one another in an efficient manner. Let's assume you are designing a microfluidic cell sorting device at your FYP project, as show below, which is a two-dimensional chancel of width 2b and length L. Cells drop into a liquid flow chamber at their terminal velocity, Vt. At x=L, there is a splitter plate that divides the flow into two downstream channels each of width b. Your goal is to design a device so that two cell populations of different size can be separated. One type, the larger cell, should end up in the lower channel and the other, the smaller cell, should flow into the upper channel. : V. b. flow splitter L CBE's FYP Project: Designing a cell sorting device with a split channel. Like what we discussed in the class, the channel conveys a flow in the x direction which has a parabolic profile with respect to y. Um is the maximum velocity at the center of the channel. (i) Can you write down the velocity profile u as a function of y? Derivation is not necessary. (4 pts) (ii) You may assume that the cell maintains its constant y-velocity, Vt, but its x- velocity matches the fluid's x-velocity. Can you write down the governing equations for the cell positions (Xp, yp) in terms of ODE (ie dxp/dt=..., dyp/dt=...). Also specify initial conditions for this problem. In addition to the variables to be solved, your equations could contain parameters Um, b, Vt. As 3 soon the values of the parameters are given, your ODE should be in an expression that could be solved by using MATLAB or Polymath software. Although vt for large and small cells are different, you don't need to worry about it at this question. The ODEs you setup can be equally applicable for large or small cells as long as the terminal velocity Vt is given. (14 pts) (iii) a Now let's do the quantitative analysis. Top inlet of cell solutions enters the channel with a volumetric flow rate Q of 0.01 cm3/sec with a uniform cell mixture solution of cell density (104 cells/cm) and 60% large cells and 40% small cells, the channel length L is 5 cm and half width of the channel b is 5 mm. If large cells can all go underneath center line of the chancel before traveling to the flow splitter, what is the cell flow rate (cells/min) of the large cells in the bottom half of the flow splitter? If the large and small cells are all spherical shape with the same mass density and the diameter of the large cells is 2 times of the small cells, what is the terminal velocity of the large cells if the small cell has a terminal velocity Vt of 500 um/sec? Justify your answer. Hint: You may assume that microfluidic channel flow has a Re smaller than one. (8 pts)