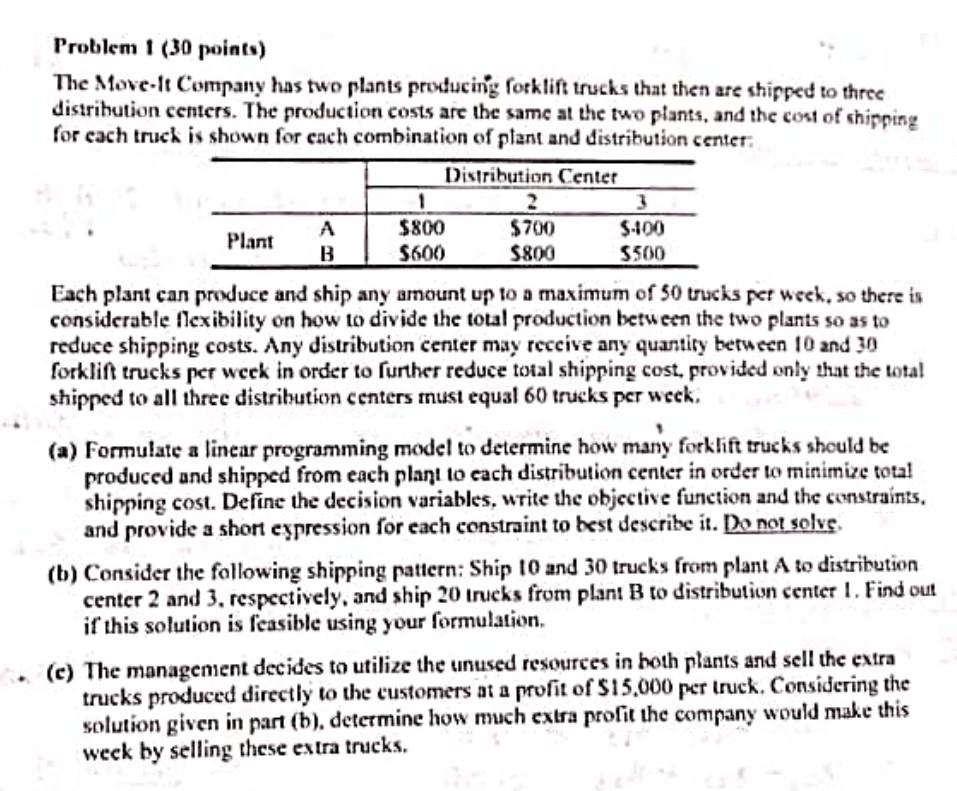

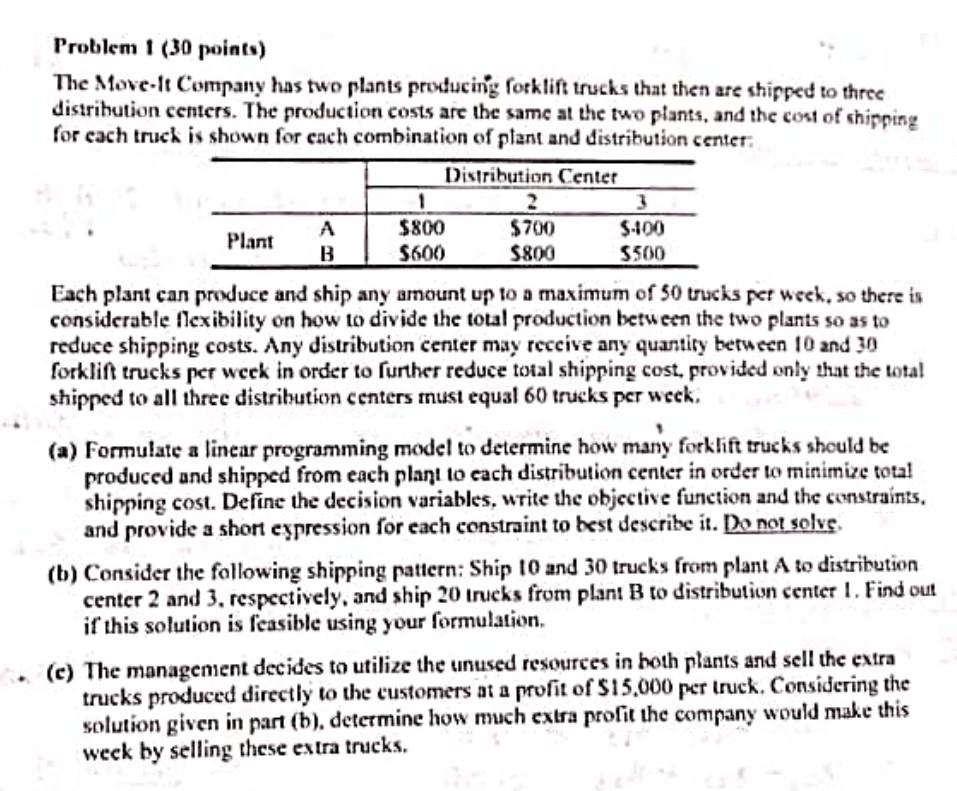

Problem I (30 pointv) The Move-It Company has two plants producing forklift trucks that then are shipped to three distribution centers. The production costs are the same at the two plants, and the cost of shipping for cach truck is shown for cach combination of plant and distribution center: Each plant can produce and ship any amount up to a maximum of 50 trucks per week, so there is considerable flexibility on how to divide the total production between the two plants so as to reduce shipping costs. Any distribution center may reccive any quantity between 10 and 30 forklift trucks per week in order to further reduce total shipping cost, provided only that the total shipped to all three distribution centers must equal 60 trucks per weck, (a) Formulate a linear programming model to determine how many forklift trucks should be produced and shipped from each plant to each distribution center in order to minimize total shipping cost. Define the decision variables, write the objective function and the constraints. and provide a short expression for each constraint to best describe it. Do not solve. (b) Consider the following shipping pattern: Ship 10 and 30 trucks from plant A to distribution center 2 and 3, respectively, and ship 20 trucks from plant B to distribution center 1 . Find out if this solution is feasible using your formulation. (c) The management decides to utilize the unused resources in hoth plants and sell the extra trucks produced directly to the customers at a profit of $15,000 per truck. Considering the solution given in part (b). determine how much extra profit the company would make this weck by selling these extra trucks. Problem I (30 pointv) The Move-It Company has two plants producing forklift trucks that then are shipped to three distribution centers. The production costs are the same at the two plants, and the cost of shipping for cach truck is shown for cach combination of plant and distribution center: Each plant can produce and ship any amount up to a maximum of 50 trucks per week, so there is considerable flexibility on how to divide the total production between the two plants so as to reduce shipping costs. Any distribution center may reccive any quantity between 10 and 30 forklift trucks per week in order to further reduce total shipping cost, provided only that the total shipped to all three distribution centers must equal 60 trucks per weck, (a) Formulate a linear programming model to determine how many forklift trucks should be produced and shipped from each plant to each distribution center in order to minimize total shipping cost. Define the decision variables, write the objective function and the constraints. and provide a short expression for each constraint to best describe it. Do not solve. (b) Consider the following shipping pattern: Ship 10 and 30 trucks from plant A to distribution center 2 and 3, respectively, and ship 20 trucks from plant B to distribution center 1 . Find out if this solution is feasible using your formulation. (c) The management decides to utilize the unused resources in hoth plants and sell the extra trucks produced directly to the customers at a profit of $15,000 per truck. Considering the solution given in part (b). determine how much extra profit the company would make this weck by selling these extra trucks