Question

Problem Statement In this design project, the complex problem of regulating the temperature of COVID vaccine ingredients at National Institute of Health (NIH) Islamabad plant

Problem Statement

In this design project, the complex problem of regulating the temperature of COVID vaccine ingredients at National Institute of Health (NIH) Islamabad plant has been investigated by determining the gain K through Routh Hurwitz and Root locus design techniques and then designing different type of compensators to regulate its transient response. By examining the design in several stages, the students can gain insight into the various aspects of the problem without being overwhelmed.

Temperature Regulator problem in COVID VACCINE MANUFACTURING PLANT

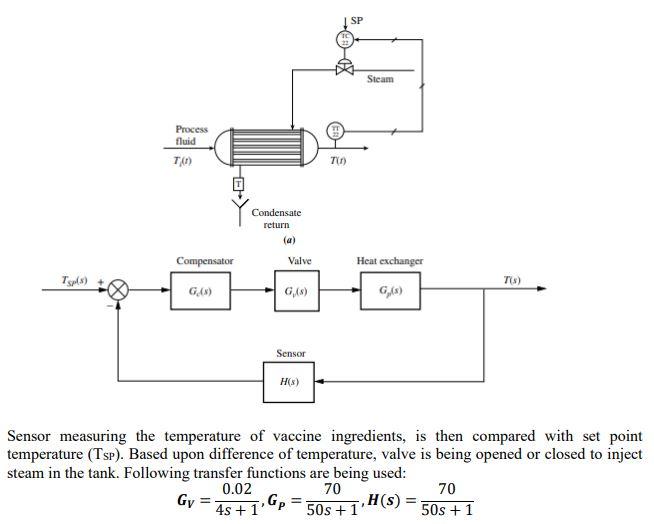

The first batch of bulk Cansino COVID vaccine is being processed at the National Institute of Health (NIH) Islamabad plant set up for this purpose last month. Vaccine ingredients are needed to be mixed at high temperature in the tank to get an effective vaccine. The tank includes temperature regulator that is being used to regulate the temperature of vaccine ingredients at set point temperature. Block diagram of the temperature regulator process is shown below.

Deliverables: (1) If GC(s) = K, Determine the value of K by Root Locus method (Draw Root Locus plot & do the calculations manually) that will yield dominant pole with zeta ( ) = 0.7. Find the value of settling time (Ts).

(2) Design a Proportional Derivative (PD) controller to obtain same damping factor but settling time should be 20% smaller than the value you found in part (1) (3) Develop a model in MATLAB/Simulink to verify your results of part (1) and (2).

(4) Design the model in part (2) and part (3) using Lead Compensator.

(5) Determine the gains for lag-lead compensator to achieve following design parameter values for step input: a. Overshoot = 10%. b. Steady State Error = 5%. c. Settling time = 60 s.

(6) Use MATLAB to validate your results of part (5)

SP Steam Process fluid TO) TIN Condensate return (a) Compensator Valve Heat exchanger Tspl) TU) () Sensor H() Sensor measuring the temperature of vaccine ingredients, is then compared with set point temperature (Tsp). Based upon difference of temperature, valve is being opened or closed to inject steam in the tank. Following transfer functions are being used: 0.02 70 70 ,Gp H(S) = 4s +1' 50s +1 50s +1 Gy SP Steam Process fluid TO) TIN Condensate return (a) Compensator Valve Heat exchanger Tspl) TU) () Sensor H() Sensor measuring the temperature of vaccine ingredients, is then compared with set point temperature (Tsp). Based upon difference of temperature, valve is being opened or closed to inject steam in the tank. Following transfer functions are being used: 0.02 70 70 ,Gp H(S) = 4s +1' 50s +1 50s +1 Gy

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started