Answered step by step

Verified Expert Solution

Question

1 Approved Answer

PROJECT: Ethylbenzene Production As a process engineer you are hired to design a chemical plant to produce 8 0 , 0 0 0 tons per

PROJECT: Ethylbenzene Production

As a process engineer you are hired to design a chemical plant to produce tons per annum a of ethylbenzene from benzene and ethylene. Benzene assumed pure and Ethylene containing mole fraction of ethylene, ethane feed are available at and Ethane is inert.

It may be assumed that the only reactions occurring are:

tableHREVTEETEEfiredethylbenzene,reactor,flash,benzene,benzene,benzene,ethylbenzene,ethylbenzene,ethylbenzeneheaterreactor,cooler,drum,tower,tower,tower,tower,tower,tower

Unit : Ethylbenzene Process

The molar ratio of benzene to ethylene are approximated at : in order to minimize yielding tri and higher ethyl benzene. The plant should operate for days in a year, to allow for shutdown and maintenance.

Calculate flow rates and composition of Benzene, Ethylene, Ethylbenzene and Diethylbenzene in each stream. Show all calculations:

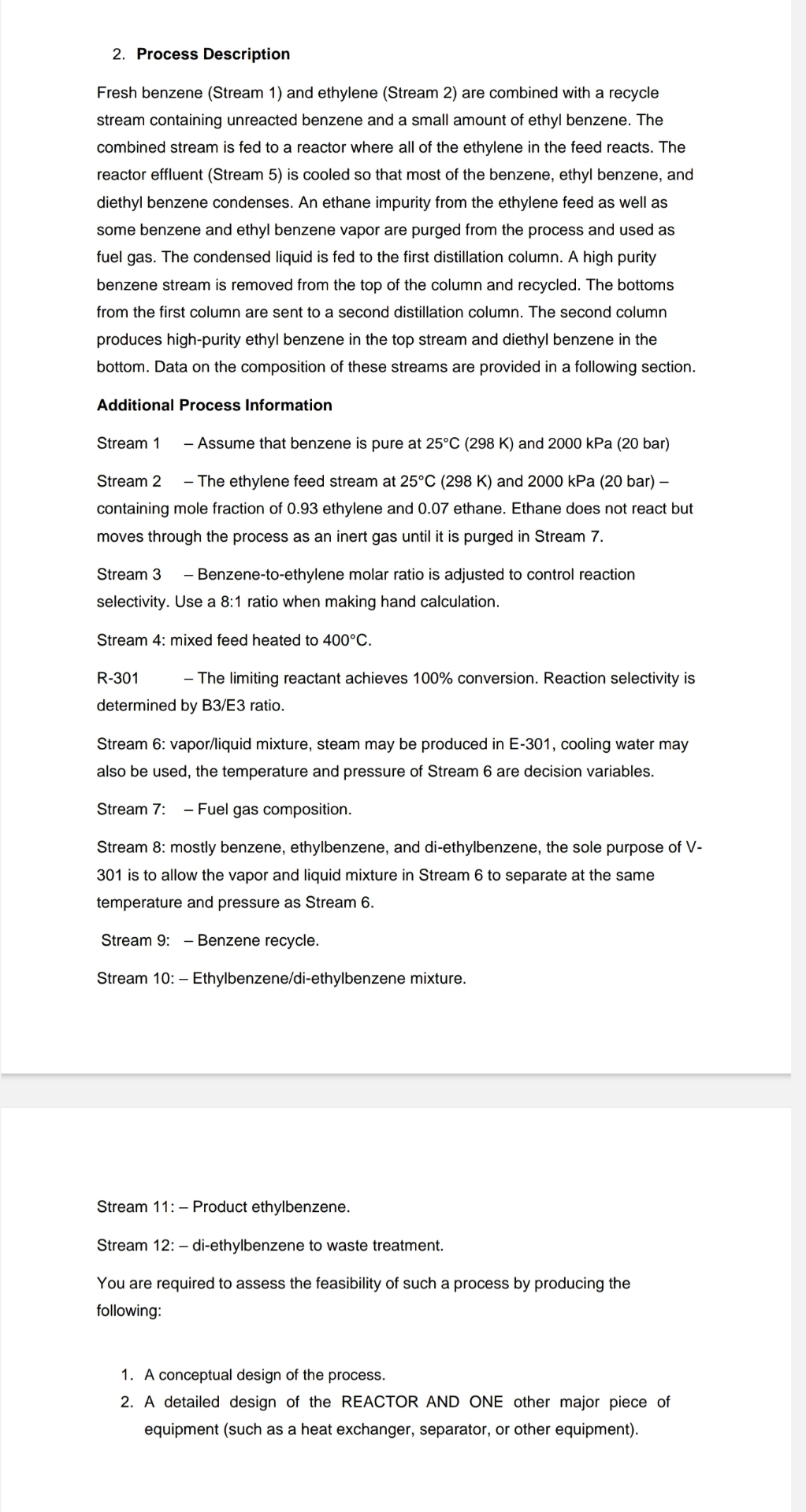

Process Description

Fresh benzene Stream and ethylene Stream are combined with a recycle stream containing unreacted benzene and a small amount of ethyl benzene. The combined stream is fed to a reactor where all of the ethylene in the feed reacts. The reactor effluent Stream is cooled so that most of the benzene, ethyl benzene, and diethyl benzene condenses. An ethane impurity from the ethylene feed as well as some benzene and ethyl benzene vapor are purged from the process and used as fuel gas. The condensed liquid is fed to the first distillation column. A high purity benzene stream is removed from the top of the column and recycled. The bottoms from the first column are sent to a second distillation column. The second column produces highpurity ethyl benzene in the top stream and diethyl benzene in the bottom. Data on the composition of these streams are provided in a following section.

Additional Process Information

Stream Assume that benzene is pure at and kPa bar

Stream The ethylene feed stream at and kPa bar containing mole fraction of ethylene and ethane. Ethane does not react but moves through the process as an inert gas until it is purged in Stream

Stream Benzenetoethylene molar ratio is adjusted to control reaction selectivity. Use a : ratio when making hand calculation.

Stream : mixed feed heated to

R The limiting reactant achieves conversion. Reaction selectivity is determined by BE ratio.

Stream : vaporliquid mixture, steam may be produced in E cooling water may also be used, the temperature and pressure of Stream are decision variables.

Stream : Fuel gas composition.

Stream : mostly benzene, ethylbenzene, and diethylbenzene, the sole purpose of V is to allow the vapor and liquid mixture in Stream to separate at the same temperature and pressure as Stream

Stream : Benzene recycle.

Stream : Ethylbenzenediethylbenzene mixture.

Stream : Product ethylbenzene.

Stream : diethylbenzene to waste treatment.

You are required to assess the feasibility of such a process by producing the following:

A conceptual design of the process.

A detailed design of the REACTOR AND ONE other major piece of equipment such as a heat exchanger, separator, or other equipment

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started