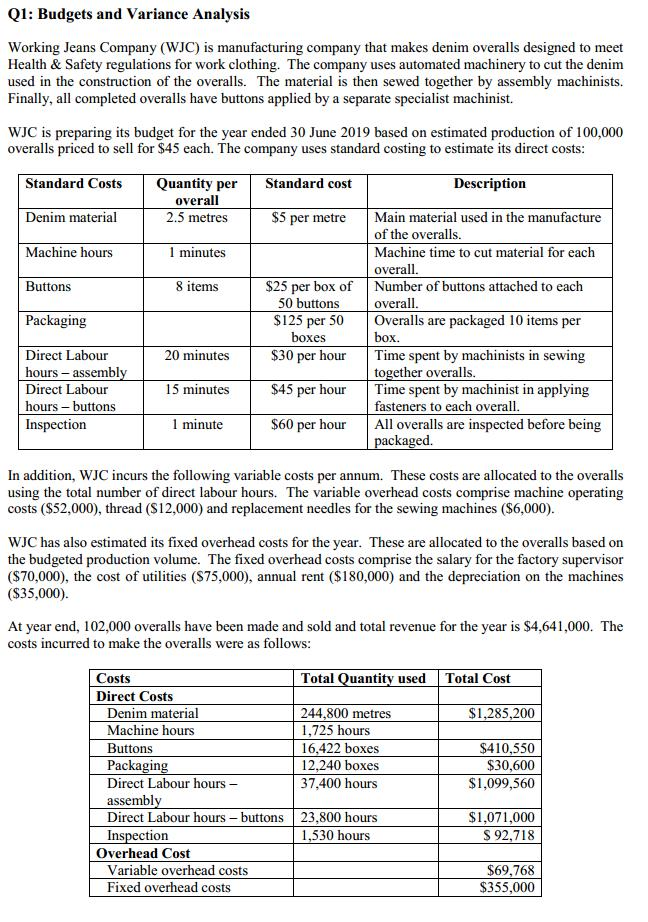

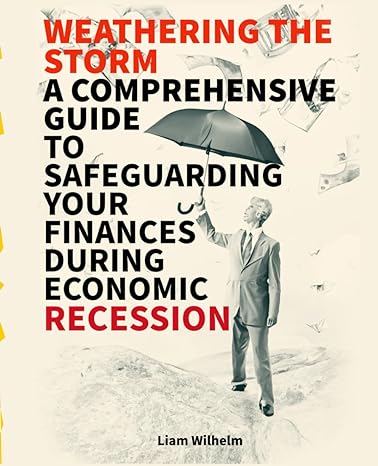

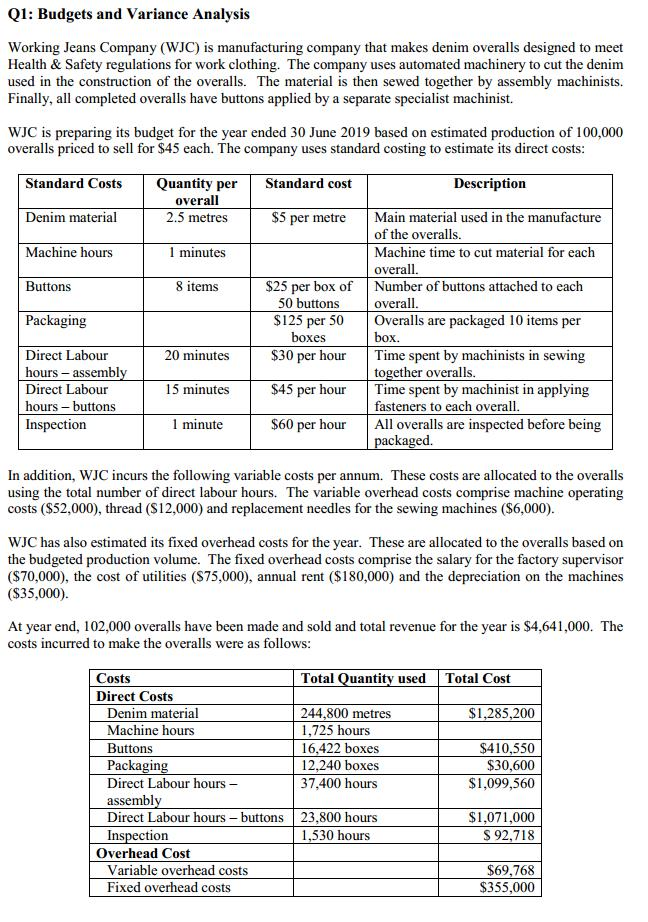

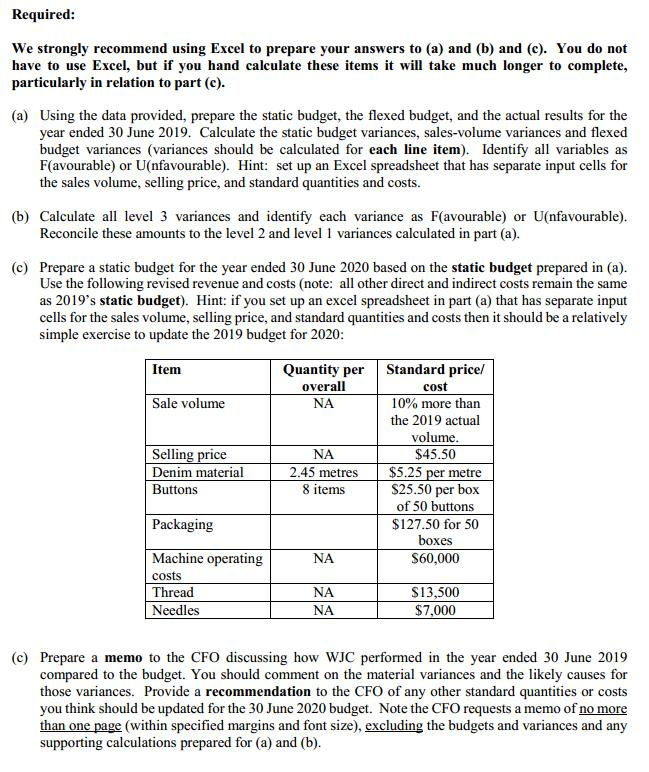

Q1: Budgets and Variance Analysis Working Jeans Company (WJC) is manufacturing company that makes denim overalls designed to meet Health & Safety regulations for work clothing. The company uses automated machinery to cut the denim used in the construction of the overalls. The material is then sewed together by assembly machinists. Finally, all completed overalls have buttons applied by a separate specialist machinist. WJC is preparing its budget for the year ended 30 June 2019 based on estimated production of 100,000 overalls priced to sell for $45 each. The company uses standard costing to estimate its direct costs: Standard Costs Standard cost Description Quantity per overall 2.5 metres Denim material $5 per metre Machine hours 1 minutes Buttons 8 items Packaging $25 per box of 50 buttons $125 per 50 boxes $30 per hour Main material used in the manufacture of the overalls. Machine time to cut material for each overall. Number of buttons attached to each overall Overalls are packaged 10 items per box. Time spent by machinists in sewing together overalls. Time spent by machinist in applying fasteners to each overall. All overalls are inspected before being packaged. 20 minutes Direct Labour hours - assembly Direct Labour hours - buttons Inspection 15 minutes $45 per hour 1 minute $60 per hour In addition, WJC incurs the following variable costs per annum. These costs are allocated to the overalls using the total number of direct labour hours. The variable overhead costs comprise machine operating costs ($52,000), thread ($12,000) and replacement needles for the sewing machines ($6,000). WJC has also estimated its fixed overhead costs for the year. These are allocated to the overalls based on the budgeted production volume. The fixed overhead costs comprise the salary for the factory supervisor ($70,000), the cost of utilities ($75,000), annual rent ($180,000) and the depreciation on the machines ($35,000). At year end, 102,000 overalls have been made and sold and total revenue for the year is $4,641,000. The costs incurred to make the overalls were as follows: Total Cost $1,285,200 Costs Total Quantity used Direct Costs | Denim material 244,800 metres Machine hours 1,725 hours Buttons 16,422 boxes Packaging 12,240 boxes Direct Labour hours - 37,400 hours assembly Direct Labour hours - buttons 23,800 hours Inspection | 1,530 hours Overhead Cost Variable overhead costs Fixed overhead costs $410,550 $30,600 $1,099,560 $1,071,000 $ 92,718 $69,768 $355,000 Required: We strongly recommend using Excel to prepare your answers to (a) and (b) and (c). You do not have to use Excel, but if you hand calculate these items it will take much longer to complete, particularly in relation to part (c). (a) Using the data provided, prepare the static budget, the flexed budget, and the actual results for the year ended 30 June 2019. Calculate the static budget variances, sales-volume variances and flexed budget variances (variances should be calculated for each line item). Identify all variables as Favourable) or Unfavourable). Hint: set up an Excel spreadsheet that has separate input cells for the sales volume, selling price, and standard quantities and costs. (b) Calculate all level 3 variances and identify each variance as Favourable) or U(nfavourable). Reconcile these amounts to the level 2 and level 1 variances calculated in part (a). (c) Prepare a static budget for the year ended 30 June 2020 based on the static budget prepared in (a). Use the following revised revenue and costs (note: all other direct and indirect costs remain the same as 2019's static budget). Hint: if you set up an excel spreadsheet in part (a) that has separate input cells for the sales volume, selling price, and standard quantities and costs then it should be a relatively simple exercise to update the 2019 budget for 2020: Item Quantity per overall NA Sale volume Selling price Denim material Buttons Standard price/ cost 10% more than the 2019 actual volume. $45.50 $5.25 per metre $25.50 per box of 50 buttons $127.50 for 50 NA 2.45 metres 8 items Packaging boxes NA $60,000 Machine operating costs Thread Needles NA NA $13,500 $7,000 (C) Prepare a memo to the CFO discussing how WJC performed in the year ended 30 June 2019 compared to the budget. You should comment on the material variances and the likely causes for those variances. Provide a recommendation to the CFO of any other standard quantities or costs you think should be updated for the 30 June 2020 budget. Note the CFO requests a memo of no more than one page (within specified margins and font size), excluding the budgets and variances and any supporting calculations prepared for (a) and (b). Q1: Budgets and Variance Analysis Working Jeans Company (WJC) is manufacturing company that makes denim overalls designed to meet Health & Safety regulations for work clothing. The company uses automated machinery to cut the denim used in the construction of the overalls. The material is then sewed together by assembly machinists. Finally, all completed overalls have buttons applied by a separate specialist machinist. WJC is preparing its budget for the year ended 30 June 2019 based on estimated production of 100,000 overalls priced to sell for $45 each. The company uses standard costing to estimate its direct costs: Standard Costs Standard cost Description Quantity per overall 2.5 metres Denim material $5 per metre Machine hours 1 minutes Buttons 8 items Packaging $25 per box of 50 buttons $125 per 50 boxes $30 per hour Main material used in the manufacture of the overalls. Machine time to cut material for each overall. Number of buttons attached to each overall Overalls are packaged 10 items per box. Time spent by machinists in sewing together overalls. Time spent by machinist in applying fasteners to each overall. All overalls are inspected before being packaged. 20 minutes Direct Labour hours - assembly Direct Labour hours - buttons Inspection 15 minutes $45 per hour 1 minute $60 per hour In addition, WJC incurs the following variable costs per annum. These costs are allocated to the overalls using the total number of direct labour hours. The variable overhead costs comprise machine operating costs ($52,000), thread ($12,000) and replacement needles for the sewing machines ($6,000). WJC has also estimated its fixed overhead costs for the year. These are allocated to the overalls based on the budgeted production volume. The fixed overhead costs comprise the salary for the factory supervisor ($70,000), the cost of utilities ($75,000), annual rent ($180,000) and the depreciation on the machines ($35,000). At year end, 102,000 overalls have been made and sold and total revenue for the year is $4,641,000. The costs incurred to make the overalls were as follows: Total Cost $1,285,200 Costs Total Quantity used Direct Costs | Denim material 244,800 metres Machine hours 1,725 hours Buttons 16,422 boxes Packaging 12,240 boxes Direct Labour hours - 37,400 hours assembly Direct Labour hours - buttons 23,800 hours Inspection | 1,530 hours Overhead Cost Variable overhead costs Fixed overhead costs $410,550 $30,600 $1,099,560 $1,071,000 $ 92,718 $69,768 $355,000 Required: We strongly recommend using Excel to prepare your answers to (a) and (b) and (c). You do not have to use Excel, but if you hand calculate these items it will take much longer to complete, particularly in relation to part (c). (a) Using the data provided, prepare the static budget, the flexed budget, and the actual results for the year ended 30 June 2019. Calculate the static budget variances, sales-volume variances and flexed budget variances (variances should be calculated for each line item). Identify all variables as Favourable) or Unfavourable). Hint: set up an Excel spreadsheet that has separate input cells for the sales volume, selling price, and standard quantities and costs. (b) Calculate all level 3 variances and identify each variance as Favourable) or U(nfavourable). Reconcile these amounts to the level 2 and level 1 variances calculated in part (a). (c) Prepare a static budget for the year ended 30 June 2020 based on the static budget prepared in (a). Use the following revised revenue and costs (note: all other direct and indirect costs remain the same as 2019's static budget). Hint: if you set up an excel spreadsheet in part (a) that has separate input cells for the sales volume, selling price, and standard quantities and costs then it should be a relatively simple exercise to update the 2019 budget for 2020: Item Quantity per overall NA Sale volume Selling price Denim material Buttons Standard price/ cost 10% more than the 2019 actual volume. $45.50 $5.25 per metre $25.50 per box of 50 buttons $127.50 for 50 NA 2.45 metres 8 items Packaging boxes NA $60,000 Machine operating costs Thread Needles NA NA $13,500 $7,000 (C) Prepare a memo to the CFO discussing how WJC performed in the year ended 30 June 2019 compared to the budget. You should comment on the material variances and the likely causes for those variances. Provide a recommendation to the CFO of any other standard quantities or costs you think should be updated for the 30 June 2020 budget. Note the CFO requests a memo of no more than one page (within specified margins and font size), excluding the budgets and variances and any supporting calculations prepared for (a) and (b)