Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Q1. REACTOR It is desired to design a packed bed reactor to produce 100000 ton Allyl Chloride (C3H5Cl) per year. Although a multiple reaction system

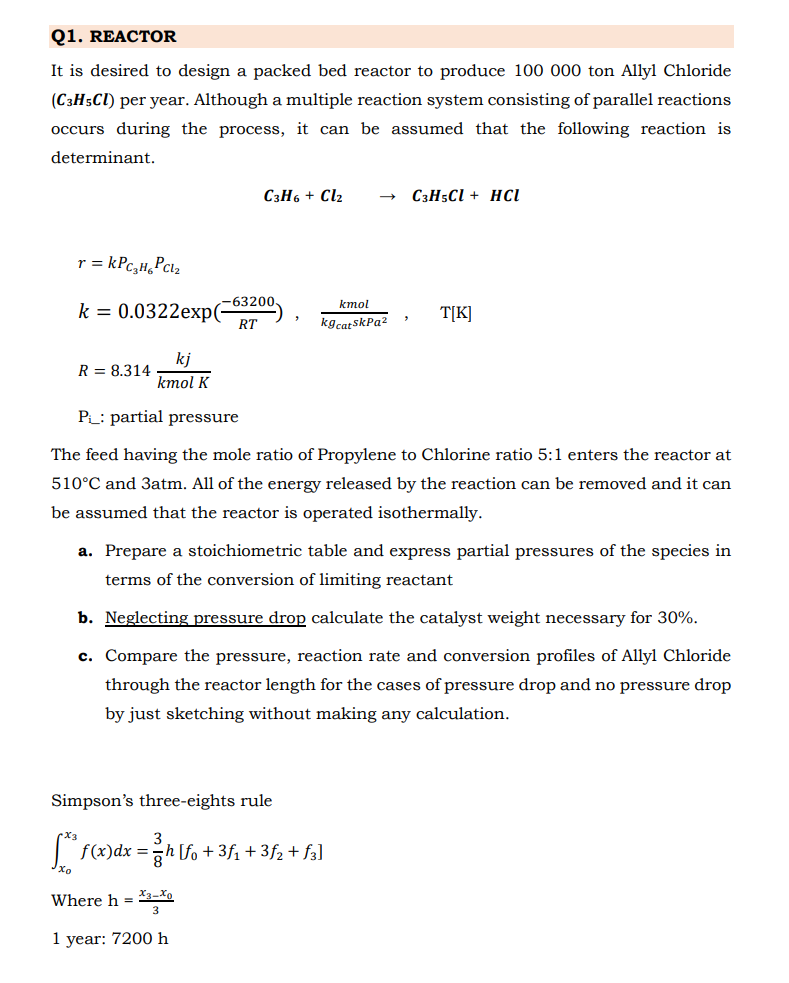

Q1. REACTOR It is desired to design a packed bed reactor to produce 100000 ton Allyl Chloride (C3H5Cl) per year. Although a multiple reaction system consisting of parallel reactions occurs during the process, it can be assumed that the following reaction is determinant. C3H6+Cl2C3H5Cl+HCl r=kPC3H6PCl2k=0.0322exp(RT63200),kgcatskPa2kmol,T[K]R=8.314kmolKkjPi_:partialpressure The feed having the mole ratio of Propylene to Chlorine ratio 5:1 enters the reactor at 510C and 3atm. All of the energy released by the reaction can be removed and it can be assumed that the reactor is operated isothermally. a. Prepare a stoichiometric table and express partial pressures of the species in terms of the conversion of limiting reactant b. Neglecting pressure drop calculate the catalyst weight necessary for 30%. c. Compare the pressure, reaction rate and conversion profiles of Allyl Chloride through the reactor length for the cases of pressure drop and no pressure drop by just sketching without making any calculation. Simpson's three-eights rule xox3f(x)dx=83h[f0+3f1+3f2+f3] Where h=3x3x0

Q1. REACTOR It is desired to design a packed bed reactor to produce 100000 ton Allyl Chloride (C3H5Cl) per year. Although a multiple reaction system consisting of parallel reactions occurs during the process, it can be assumed that the following reaction is determinant. C3H6+Cl2C3H5Cl+HCl r=kPC3H6PCl2k=0.0322exp(RT63200),kgcatskPa2kmol,T[K]R=8.314kmolKkjPi_:partialpressure The feed having the mole ratio of Propylene to Chlorine ratio 5:1 enters the reactor at 510C and 3atm. All of the energy released by the reaction can be removed and it can be assumed that the reactor is operated isothermally. a. Prepare a stoichiometric table and express partial pressures of the species in terms of the conversion of limiting reactant b. Neglecting pressure drop calculate the catalyst weight necessary for 30%. c. Compare the pressure, reaction rate and conversion profiles of Allyl Chloride through the reactor length for the cases of pressure drop and no pressure drop by just sketching without making any calculation. Simpson's three-eights rule xox3f(x)dx=83h[f0+3f1+3f2+f3] Where h=3x3x0 Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started