Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Q7. (10%) A chemical plant stores raw materials, finished goods and intermediate products in tanks. The materials are pumped to and from the various processing

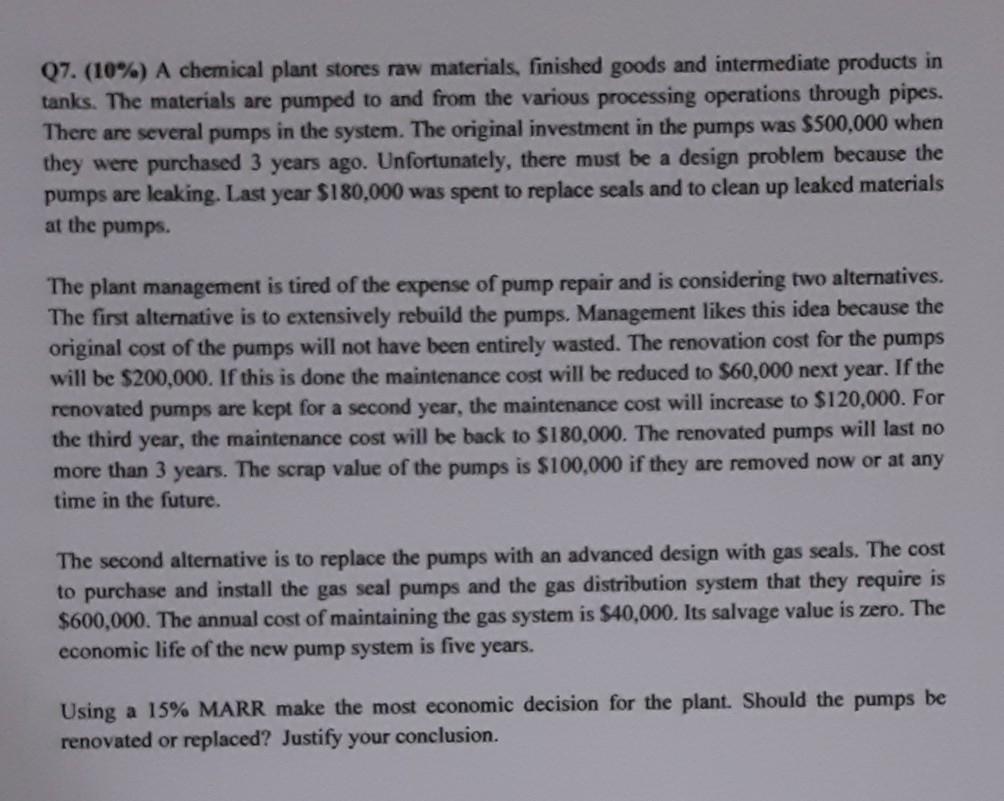

Q7. (10%) A chemical plant stores raw materials, finished goods and intermediate products in tanks. The materials are pumped to and from the various processing operations through pipes. There are several pumps in the system. The original investment in the pumps was $500,000 when they were purchased 3 years ago. Unfortunately, there must be a design problem because the pumps are leaking. Last year $180,000 was spent to replace seals and to clean up leaked materials at the pumps. The plant management is tired of the expense of pump repair and is considering two alternatives. The first alternative is to extensively rebuild the pumps. Management likes this idea because the original cost of the pumps will not have been entirely wasted. The renovation cost for the pumps will be $200,000. If this is done the maintenance cost will be reduced to $60,000 next year. If the renovated pumps are kept for a second year, the maintenance cost will increase to $120,000. For the third year, the maintenance cost will be back to S180,000. The renovated pumps will last no more than 3 years. The scrap value of the pumps is $100,000 if they are removed now or at any time in the future. The second alternative is to replace the pumps with an advanced design with gas seals. The cost to purchase and install the gas seal pumps and the gas distribution system that they require is $600,000. The annual cost of maintaining the gas system is $40,000. Its salvage value is zero. The economic life of the new pump system is five years. Using a 15% MARR make the most economic decision for the plant. Should the pumps be renovated or replaced? Justify your conclusion Q7. (10%) A chemical plant stores raw materials, finished goods and intermediate products in tanks. The materials are pumped to and from the various processing operations through pipes. There are several pumps in the system. The original investment in the pumps was $500,000 when they were purchased 3 years ago. Unfortunately, there must be a design problem because the pumps are leaking. Last year $180,000 was spent to replace seals and to clean up leaked materials at the pumps. The plant management is tired of the expense of pump repair and is considering two alternatives. The first alternative is to extensively rebuild the pumps. Management likes this idea because the original cost of the pumps will not have been entirely wasted. The renovation cost for the pumps will be $200,000. If this is done the maintenance cost will be reduced to $60,000 next year. If the renovated pumps are kept for a second year, the maintenance cost will increase to $120,000. For the third year, the maintenance cost will be back to S180,000. The renovated pumps will last no more than 3 years. The scrap value of the pumps is $100,000 if they are removed now or at any time in the future. The second alternative is to replace the pumps with an advanced design with gas seals. The cost to purchase and install the gas seal pumps and the gas distribution system that they require is $600,000. The annual cost of maintaining the gas system is $40,000. Its salvage value is zero. The economic life of the new pump system is five years. Using a 15% MARR make the most economic decision for the plant. Should the pumps be renovated or replaced? Justify your conclusion

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started