Question

Quality Pretzels Inc. makes chocolate-covered pretzels and other snacks in its Waco plant. Its products are sold in 5-pound metal containers, which are also manufactured

Quality Pretzels Inc. makes chocolate-covered pretzels and other snacks in its Waco plant. Its products are sold in 5-pound metal containers, which are also manufactured at the Waco plant. In June 2014, the plant manager, Sarah Cassidy, was approached by Texas Canister Company with an offer to supply the canisters at a price of $1 each. Quality Pretzels assigns the following direct costs to canister production, corresponding to a volume of 760,000 canisters:

Direct Material: $300,000

Direct Labor (12,000 hours at $15 per hour ) : $180,000

Both direct costs are considered variable. The company assigns variable overhead at $10 per direct labor hour and fixed manufacturing overhead at $45 per direct labor hour. Cassidy views this decision as a long-term decision because she expects that her fixed costs will decrease should she decide to accept the offer from Texas Canister Company. Assume that cost is the only consideration in her decision-making process (i.e., dimensions such as quality and delivery reliability are not relevant).

Required

- Based on the direct-labor-based product costing system in place, would Cassidy be inclined to accept the order?

- Never a fan of the direct-labor-based system, Cassidy performs her own analysis and determines that only $80,000 of supervisor salaries and $28,000 of machinery depreciation can be avoided from the fixed manufacturing overhead if she buys the canisters from Texas Canister Company. Based on this information, would Cassidy be inclined to accept the order? Show your computations.

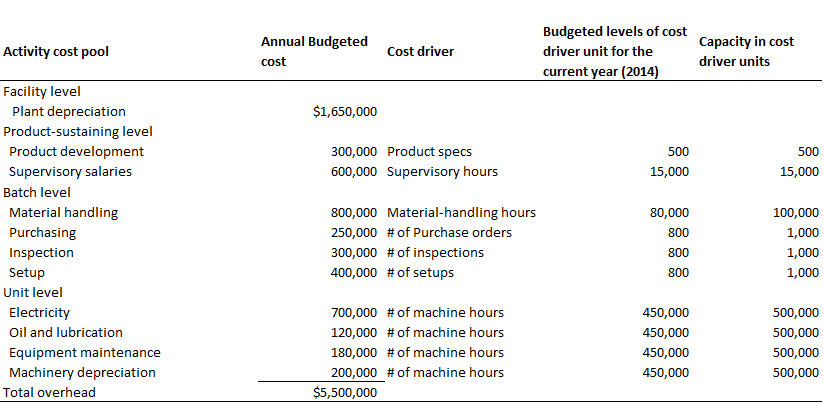

- Meanwhile, the controller of Quality Pretzels, Dave Paxon, had performed an activity-based costing analysis of Qualitys overall cost structure. His analysis is captured in the following exhibit:

Dave provides data both on capacity and on budgeted volume for 2014 because the volume in 2014 is unusually low, relative to a typical year in which capacity is used fully. Going forward, there is every expectation that capacity will be utilized fully. Assume now that Sarah consults Dave about the decision. Moreover, after further analysis, she concludes that the cost driver levels associated with canister production are as follows: 10 product specs, 2,000 supervisory hours, 6,000 material-handling hours, 30 inspections, 15 setups, 55 purchase orders, and 70,000 machine hours. Based on this information, would Sarah make or buy? How much would she save for the company with her decision? Show your computations.

- Many skeptics argue that activity-based costing is just a fancy way of allocating fixed costs. In your opinion, under what conditions would activity-based costing systems provide useful and appropriate cost bases for long-term product planning and capacity planning decisions?

Budgeted levels of cost Annual Budgeted Capacity in cost Activity cost pool Cost driver driver unit for the driver units cost current year (2014) Facility level Plant depreciation $1,650,000 Product-sustaining level Product development 300,000 Product specs 500 500 600,000 Supervisory hours Supervisory salaries 15,000 15,000 Batch level Material handling 800,000 Material-handling hours 80,000 100,000 Purchasing 250,000 of Purchase orders 800 1,000 300,000 #of inspections 400,000 #of setups Inspection 800 1,000 Setup 800 1,000 Unit level Electricity 700,000 of machine hours 450,000 500,000 Oil and lubrication 120,000 #of machine hours 450,000 500,000 180,000 #of machine hours Equipment maintenance 450,000 500,000 200,000 #of mach ine hours Machinery depreciation Total overhead 450,000 500,000 $5,500,000 Budgeted levels of cost Annual Budgeted Capacity in cost Activity cost pool Cost driver driver unit for the driver units cost current year (2014) Facility level Plant depreciation $1,650,000 Product-sustaining level Product development 300,000 Product specs 500 500 600,000 Supervisory hours Supervisory salaries 15,000 15,000 Batch level Material handling 800,000 Material-handling hours 80,000 100,000 Purchasing 250,000 of Purchase orders 800 1,000 300,000 #of inspections 400,000 #of setups Inspection 800 1,000 Setup 800 1,000 Unit level Electricity 700,000 of machine hours 450,000 500,000 Oil and lubrication 120,000 #of machine hours 450,000 500,000 180,000 #of machine hours Equipment maintenance 450,000 500,000 200,000 #of mach ine hours Machinery depreciation Total overhead 450,000 500,000 $5,500,000

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started